Applied Physics

Vol.08 No.05(2018), Article ID:25153,13

pages

10.12677/APP.2018.85032

Progress and Applications of Active Optical Fibers

Bingtao Zhang, Yue’e Chen, Zigang Zhao, Yong Wang*

Laser Research Institute, Qilu University of Technology (Shandong Academy of Sciences), Qingdao Shandong

Received: May 8th, 2018; accepted: May 22nd, 2018; published: May 29th, 2018

ABSTRACT

First in this paper, we introduce the concept and principle of rare-earth doped active optical fibers, and review the development of active fibers in recent years. Second, we introduce the design and preparation technology of active optical fiber. Third, we discuss the characteristics and development of various types of active optical fibers, and introduce the applications of active optical fiber in fiber lasers and sensors. Especially from our works, it is seen that the fiber quality and lasing performance can be significantly improved through the optimization of the fabrication process. Finally, we discuss some disadvantages of active optical fibers and provide insights into the overall situation, challenges and prospective of active optical fibers.

Keywords:Rare-Earth Doped Active Fiber, Photonic Crystal Fiber, Large-Mode-Area Fiber, High Power Fiber Laser, Active Fiber Sensor

有源光纤的进展与应用

张炳涛,陈月娥,赵兹罡,王勇*

齐鲁工业大学(山东省科学院),激光研究所,山东 青岛

收稿日期:2018年5月8日;录用日期:2018年5月22日;发布日期:2018年5月29日

摘 要

本文首先简要介绍了有源光纤的概念和原理,回顾了不同稀土掺杂有源光纤的近几年发展情况,然后简单介绍了有源光纤的设计与制造技术,并讨论了各类型有源光纤的特点和最近的发展,重点介绍了有源光纤在光纤激光器和传感器领域的应用,特别是我们所研发的掺杂光纤和光纤激光器,通过制造工艺优化可明显提高光纤质量和激光性能,最后阐述了现阶段有源光纤的缺点,对有源光纤的进一步发展和研究进行了展望。

关键词 :稀土掺杂有源光纤,光子晶体光纤,大模场光纤,高功率光纤激光器,有源光纤传感器

Copyright © 2018 by authors and Hans Publishers Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

1. 引言

光纤是光导纤维的简称,由纤芯和包层组成,因其体积小、重量轻、抗电磁干扰、光束质量好、耐高温及成本低等众多优点,在通信、医学、艺术、探测、激光器和传感等领域有着重要的应用 [1] [2] [3] [4] [5] 。最初,光纤主要是用来导光,纤芯中没有掺杂稀土元素,被称为无源光纤。随着研究的深入和需求的提高,开始在纤芯中掺杂稀土元素等激活离子,并通过泵浦使光纤发光,使无源光纤被“激活”,成为掺杂有源光纤。一般在有源光纤中掺入一种或多种稀土元素,如钕(Nd)、镱(Yb)、铒(Er)、铥(Tm)、钬(Ho)、镝(Dy)、镨(Pr)等,利用其产生新的光波或放大光信号。表1给出了上述几种常见的稀土元素对应的激光输出波段。可以看到,每个稀土元素的发射谱有多根谱线,甚至构成连续谱,多个稀土元素发射从可见光到中红外。

Table 1. Laser wavelengths of different rare earth doped fibers

表1. 各稀土元素掺杂光纤的激光波长

众所周知,有源光纤作为增益介质,是光纤激光器/放大器中不可或缺的一部分,使光纤激光器在可见光、近红外到中红外波段中都实现了一系列的激光输出,并且有源光纤在窄线宽、单频、连续或者脉冲激光器中的作用显得尤为突出。近些年,为了进一步提高激光器的输出功率、输出激光的品质和扩展光纤激光器的应用,在纤芯中掺杂更高浓度的稀土元素和设计有源光纤的新型结构成为解决问题的关键,并随之也出现了一些多边形、D型、单模、大模场、光子晶体和高浓度掺杂等有源光纤。另外,光纤传感器兴起已有40多年 [6] ,因具有高灵敏、低成本和小型化等优点备受关注,且很多光纤传感器都以无源光纤为基础,为了使得光纤传感技术进一步提升,发现在一些传感器中使用有源光纤代替无源光纤更有优势。

2. 多种有源光纤的最新进展

根据有源光纤中所掺稀土元素的种类,可将有源光纤细分为掺钕光纤、掺镱光纤、掺铒光纤、掺铥光纤、掺钬光纤、铒镱共掺光纤和铥钬共掺光纤等掺杂光纤。我们知道每种稀土元素的能级是固定的,但是在不同基质材料中的电场环境不同,能级分裂不一样,所以导致光谱输出会有所区别。而且基质材料的结构、吸收系数、导热系数和折射率等参数不同,不仅会限制激活离子的掺杂浓度,也会影响各波长光的传输特性,特别是光纤的不同结构,都会使光纤的性能不同。下面就几种稀土掺杂光纤的发展进行讨论。

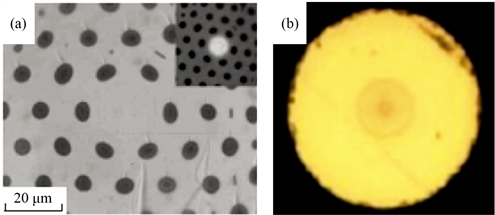

钕元素被研究的较早,也相对成熟,而掺钕光纤的研究也比较多 [7] 。利用掺钕石英光纤激光器已在许多波长处实现了激光输出,如910~925 nm的激光输出 [7] 、1064 nm附近的激光输出 [9] 以及900 nm以下的激光输出 [27] 。此外,磷酸盐玻璃可以掺杂较高浓度的稀土离子,一些不同类型的掺钕磷酸盐光纤(如传统光纤和光子晶体光纤)已被制备出来,并在1056 nm处实现了激光输出 [28] [29] 。图1(a)展示了掺钕的磷酸盐微结构光纤 [29] 。图1(a)展示了掺钕的磷酸盐微结构光纤。相比石英玻璃,硅酸盐玻璃具有较好的化学稳定性和机械性能,可以掺杂较多的稀土离子,所以掺钕的硅酸盐玻璃光纤常被使用。2018年,Wang等在硅酸盐玻璃中掺钕元素,制备了芯40 μm单模的多通道光纤,并获得了斜效率为54%、最大功率8.4 W的激光输出 [30] 。

在众多稀土元素中,镱离子(Yb3+)具有两个能级态、不存在激发态吸收、转换效率高、荧光寿命长、吸收带较宽和不易出现浓度猝灭等诸多优点而受人们的青睐。已用掺镱的石英光纤实现了高功率激光的输出,例如Liao等利用自制的单根20/400掺镱的石英光纤,在1080 nm处实现了500 W的连续激光输出,斜效率为76.4%,接近理论极限值 [14] 。近年,在传统石英光纤的基础上进行改良,发展了一种基座设计的掺镱铝硅酸盐光纤,使该光纤具备低光子暗化效应、高信噪比和高的效率 [31] 。但针对市面上石英

Figure 1. Cross sections of optical fibers: (a) Nd-doped phosphate MOF, (b) Ho-doped tellurium tungstate fiber

图1. 几种有源光纤的横截面:(a) 掺钕的磷酸盐微结构光纤,(b) 掺钬的碲钨酸盐光纤

光纤的缺陷,一些掺镱特种光纤也被相继开发:如一种掺镱的磷酸盐纤芯的全固态光子晶体光纤,镱的掺杂量达到了16 wt% [11] ;一种掺镱的磷酸盐纤芯和硅酸盐包层的双包层混合光纤 [32] ;一种无光子暗化效应的掺镱马鞍形光纤 [33] 。

提及掺铒光纤,首先想到的是掺铒光纤放大器(EDFA),打破了光纤通信距离受光纤损耗的限制,近几十年,掺铒光纤也不局限于传统的石英材料作为基质,许多新的基质材料和新型的掺铒光纤不断涌现:Li等设计和制造了一种周围具有六个光敏子芯的掺铒石英光纤,克服了MCVD和溶解掺杂技术中的锗和铒元素不能同时高掺的困难 [34] ;Kuhn等报道了40 μm的芯径和<0.04的NA的大模场掺铒光子晶体光纤,在1556 nm处实现了超过70 W的单频输出功率 [35] ;大芯径和大的有效截面积的掺铒光纤的制备也常见报道 [36] [37] ;在掺铒光纤中,常常把镱和铒共掺进基质中,使镱起到敏化剂的作用,来增大铒泵浦吸收和铒的受激发射 [38] [39] [40] [41] 。

多用掺铥光纤获得1.6~2 μm的激光,特别是2 μm附近的激光位于人眼安全的波段,因此具有广泛的应用前景,目前以已商业化的石英基质的掺铥光纤的研究居多,但掺铥的氟化物光纤 [42] 、硅酸盐光纤 [43] 、锗酸盐光纤 [44] 、碲酸盐光纤 [45] 、碲钨酸盐光纤 [46] 和光子晶体光纤 [47] 等也都被报道。在掺铥的光纤中,也常把镱掺进去作为敏化剂,来获得更高的增益 [48] 。近年掺铥的光纤发展也较迅速,在2015年,掺铥的硅酸盐光纤在1945 nm处已获得了5.8 dB/cm的高增益 [49] ;2016年,掺铥的BGG玻璃单模光纤,铥的掺杂浓度高达7.6 × 1020/cm3 [50] 。

掺钬、镝和镨等元素的有源光纤的发射波段有些在红外区,而红外透过率低的石英基质不能再满足传输要求,所以一般选择具有红外传输性能好的硫系玻璃或者氟化物玻璃等作为基质制作光纤,由于这两种玻璃都较难制备,增加了制备掺杂上述元素光纤的难度。早在2003年就有关于在石英光纤中共掺镱和钬的报道 [19] 。后来铥和钬共掺的石英光纤也被报道 [51] 。近年,掺钬的铝锗硅玻璃光纤也被制作出来,并在890 nm、653 nm、551 nm和1726 nm处观察到了强烈的吸收峰 [52] 。最近,又第一次在掺钬的碲钨酸盐光纤上获得了2 μm的激光输出,光纤截面如图1(b) [53] 。2008年,Park等报道了掺镝的Ge-As-S玻璃光纤,并实现了2.96 μm的激光输出 [22] 。后来,Tsang和El-Taher又报道了掺镝的ZBLAN玻璃光纤,并用1088 nm的激光泵浦,得到了3 μm的激光输出 [54] 。掺镨的光纤在上世纪九十年代就有报道,并得到了蓝光的输出 [23] [55] 。近来,利用制作掺镨的防水氟铝酸盐玻璃光纤 [24] [25] 和GeAsGaSe玻璃光纤 [26] 分别在638 nm、522 nm和3.5~5.5 μm波段处实现了激光输出。

3. 有源光纤设计与制造技术

有源光纤的制备工艺基本与无源光纤的一样,只是多了掺杂稀土元素这一过程。目前最为成熟的制备工艺有:改进的化学汽相沉积法(Modified Chemical Vapour Deposition) [56] ;等离子化学汽相沉积法(Plasma Chemical Vapour Deposition) [57] ;管外汽相沉积法(Outside Vapour Deposition);汽相轴向沉积法(Vapour Phase Axial Deposition) [58] 。四种气相沉积法的工作原理基本一样:将液态SiCl4和起掺杂作用的液态卤化物,在一定条件下进行化学反应而生成掺杂的高纯石英玻璃。只是上述四种气相沉积法的热源、反应机理、沉积位置和生长方向不同。气相沉积法选用的原料纯度极高,气相沉积工艺中选用高纯度的氧气作为载气,将汽化后的卤化物气体带入反应区,从而可进一步提纯反应物的纯度,达到严格控制过渡金属离子和羟基的目的,并且可生产出高质量的光纤,生产速度也较快,所以目前商业化的光纤一般都使用气相沉积法生产。其实气相技术也有不足之处,如原料昂贵,工艺复杂,设备资源投资大,玻璃组成范围窄,掺杂浓度低,折射率调节范围小等。为克服这些缺陷,一些非气相沉积的光纤制备工艺被开发出来,并且因所需的设备成本低被广泛运用于科研当中。由于原料纯度和制作环境等因素的限制,非气相沉积工艺制作的光纤一般损耗较大,且不易在工业上实现大规模生产。常用的非气相沉积工艺有:熔融法(DM);溶胶–凝胶法(SOL-GEL);机械挤压成型法(MSP);界面凝胶法(BSG);玻璃分相法(PSG)和气相沉积–溶液法(MCVD-Solution Method)。

熔融法是将多种试剂粉末和稀土元素粉末混合,高温融化,冷却制得玻璃,然后加工成玻璃棒,拉制成光纤。该方法较常见,使用也比较广泛,稀土离子的掺杂浓度较高。

溶胶–凝胶法 [59] 是将酯类化合物或金属醇盐溶于有机溶剂中,形成均匀溶液,然后加入其它组分材料,在一定温度下发生水解、缩聚反应形成凝胶,最后经干燥、热处理、烧结制成光纤预制棒,最后通过管棒法拉制成光纤。该法掺杂稀土元素均匀,反应温度低。

气相沉积–溶液法 [60] [61] 是先用MCVD法制做出石英棒,然后放入含有稀土离子的溶液中浸泡,再进行烧结处理。图2是一种气相沉积原地溶液掺杂法的工艺步骤 [60] :首先,如传统的MCVD法一样,先在高纯石英管内沉积无掺杂的包层,然后降低温度沉积疏松芯层,保证芯层具有良好的多孔性;接着,无需取下石英管浸泡在掺杂溶液中,而是在高纯石英管的一端放置一个小直径的玻璃管,小玻璃管的一端通疏松芯层,另一端连接泵和稀土掺杂溶液,通过泵将掺杂溶液输送到疏松芯层内,一旦疏松芯层被整个浸泡,立即撤回传输玻璃管,并向石英管内填充惰性气流,整个过程中保持石英管旋转;完成干燥后,烧结掺杂的疏松芯层为玻璃层,烧缩石英管、包层和芯层,即得到实心预制棒。这种方法制作的光纤损耗小,稀土离子的掺杂浓度比传统MCVD法的高,而且可以通过多次浸泡进一步提高掺杂浓度,掺杂均匀性、灵活性较好,且可掺杂含稀土元素的纳米颗粒,使光纤具有较突出的光谱性质,因而在实验和商用稀土掺杂光纤的制作上得到广泛应用。

在用以上几种方法制作预制棒后,预制棒表面可能会留下裂纹或者杂质离子,所以一般采用Etoh、Meoh、丙酮、MEK等有机溶剂或酸清洗预制棒表面,或者使用火焰抛光预制棒,或将以上几种方法结合使用。

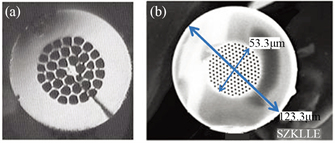

不同的制造技术对光纤的质量有很大影响,而且其中的制作工艺优化和光纤设计也很关键,如图3(a)所示是本实验室利用堆积法制作的掺铒光子晶体光纤的端面,从图中可看到包层空气孔的排列位置不整齐,空气孔大小不一且不圆,与设计不符,这都会影响到光纤的性能。经过对光纤重新设计和对制作工艺的优化,再次制作的掺铒光子晶体光纤得到很大的改善,性能也得到了很大的提升,其端面如图3(b),从图中可看出包层空气孔排列整齐,气孔呈圆形且大小均一,与设计相符。

Figure 2. Process steps of MCVD with solution doping

图2. 气相沉积原地溶液掺杂法

4. 各类型有源光纤简介

如果按照光纤的模式、芯径和模场面积等参数来分类,有源光纤可分为多模有源光纤、单模有源光纤、大芯径大模场有源光纤和少模有源光纤。每类有源光纤都有一定的优点和不足,下面讨论各类型有源光纤的特点。

有源多模光纤一般芯径较大,相比普通掺杂单模光纤具有较高的耦合效率,可掺杂较多的稀土元素 [62] ,掺杂的种类也很多,易于制作,容易实现大功率高能量的激光输出 [63] ,受到人们的青睐。多模光纤早已商业化,多家公司可以生产,如美国的Nufern、nLIGHT、加拿大的Coractive和中国的长飞和烽火等。

由于多模光纤的模式较多,光斑质量不高但利用单模有源光纤产生的激光,具有较好的光斑质量,且无模式色散,在激光器光源领域具有重要的应用 [64] [65] 。早在1986年,Poole等人就研制出第一根单模掺铒石英光纤,并利用该光纤制作了第一台掺铒光纤激光器 [56] 。近年来,利用稀土掺杂的单模光纤已实现了较高功率激光输出: Wang等利用掺镱的光纤实现了功率为2.04 kW的高功率近单模激光输出 [66] ;Beier等从掺镱的光纤放大器中获得了功率为4.3 kW的单模激光输出 [67] 。

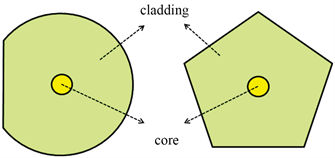

近数十年来,随着注入功率和掺杂浓度的不断提高,有源光纤的非线性效应(受激拉曼散射、受激布里渊散射、自相位调制等)成为了进一步提高功率的最大障碍,而解决这一问题的有效方法是制备大模场光纤。很快大模场光纤就被开发出来,nLIGHT公司研发了芯径10~30 μm的掺镱大模场光纤,NUFERN公司研发了芯径10~40 μm的掺镱、铒、铥和钬等的大模场光纤。一些研究机构采用特殊结构和材料的大模场有源光纤进行激光器的研究,获得了较高的能量脉冲和值功率。2010年,Paul等报道了芯径为30~35 μm掺镱的D形和五边形大芯径光纤 [61] ,图4为这两种光纤的端面示意图 [61] 。Shi等利用34 cm长高掺镱的大模场磷酸盐光纤,实现了重复率500 kHz、脉冲能量21.2 μJ、峰值功率0.96 MW的脉冲激光 [68] 。另外,也有学者利用光子晶体光纤的奇异特性,制备了大模场光子晶体光纤,获得较大的模场面积:2005年,Glas等设计了掺钕的大芯单环五孔的微结构光纤,该光纤单横模的模场面积超过了200 μm2 [69] 。

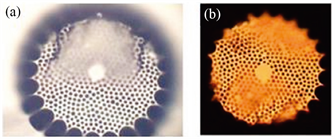

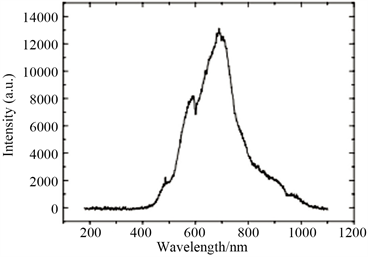

图5(a)是本实验室利用堆积法制作的掺镱双包层大模场光子晶体光纤,该光纤的纤芯径为14.12 μm,内包层空气孔直径d = 4.51 μm,Λ = 6.77 μm。通过CCD成像可得到光纤远场和近场的模场分布图。如图5(b)所示是用CCD观察了光在光纤传输时的光纤端面图,从图中我们可以看出光纤的结构很清晰的显现出来,说明实验中光纤和光学系统耦合的很好,大部分光被束缚在纤芯和包层中。对该光纤进行通光测试,用光谱仪记录200~1100 nm波长的透射光强,如图6所示为不同波长下光纤出射端面的光强分布。从图中可看出大约在700 nm处的光强最大,在<400 nm和>1100 nm处光强接近0,即表示该光纤使用范围是400~1100 nm,在700 nm附近有较高的透过率。

虽然稀土掺杂的大模场光纤解决了高功率带来的问题,但是随着芯径的增大,光纤输出模式也随之增多,导致输出的光束质量严重恶化,不再适用一些要求较高的精密加工等用途,所以单模大模场有源光纤引起了人们的极大关注。传统阶跃型单模光纤的传输条件如下:

(1)

其中V为归一化截止频率,a为光纤芯径,NA为数值孔径。根据(1)式我们知道,要想实现单模传输,a与NA成反比关系。大模场光纤要求大的芯径,那就必然要压缩NA,但由于气相沉积制备工艺的限制,商业化的石英单模有源光纤的NA一般大于0.06,致使芯径无法增大(一般为6~10 μm)。较小的芯径导致光纤耦合效率低和非线性效应严重,所以单模大芯径有源光纤的研究十分迫切。目前,单模大模场光纤

Figure 3. SEM photographs of Er-doped photonic crystal fiber cross sections: (a) before optimization, (b) after optimization

图3. 掺铒光子晶体光纤横截面的扫描电镜图片:(a) 优化前,(b) 优化后

Figure 4. Schematic diagrams of the end face of D-shaped and pentagon-shaped optical fibers

图4. D形和五边形光纤的端面示意图

Figure 5. Cross sections of a Yb-doped double-cladding large-mode-area photonic crystal fiber

图5. 镱掺杂的双包层大模面积光子晶体光纤端面图

Figure 6. Emission spectrum in 200~1100 nm

图6. 200~1100 nm波段光纤发射谱

主要有传统结构单模光纤、布拉格光纤和光子晶体光纤。早在1997年,英国的南安普顿大学就报道了模场面积为310 μm2的掺铒单模光纤,数值孔径接近0.06 [70] 。2016年,Peng等设计了掺镱的铝磷硅单模大模场光纤,该光纤拥有超低的数值孔径0.036,基模的模场面积为550 μm2 [71] 。而布拉格光纤目前仍处于理论优化和仿真研究阶段,商业化的有源布拉格光纤还很少。北京交通大学报道了一种高浓度掺铒的非均匀Bragg结构光纤 [72] 。Yehouessi等报道了一种芯径超过100 μm的布拉格光纤,在1035 nm处有效模场面积达到了3700 μm2 [73] 。由于单模大模场光子晶体光纤的模场面积可达到几千平方微米 [74] ,比传统单模大模场光纤更具优势,而光子晶体光纤的制备工艺相对成熟,所以单模大模场光纤的研究则转向了光子晶体光纤,同时发展了一些40 μm以上的大芯径单模光子晶体光纤,实现了较高的斜效率和转换效率。2015年,Li等制作了一种45 μm芯径单模掺钕的硅酸盐玻璃全固态光子晶体光纤,并获得了单模激光输出 [75] 。2016年,Wang等用镱-铝-磷共掺的石英玻璃作为纤芯,拉制了芯径50 μm的光子晶体光纤,由于泵浦功率的限制,最大输出功率为46 W,斜效率为61% [59] 。

过去的20多年里,我国光通信技术发展迅速,通信信道的容量接近香农极限,被寄予厚望的空分复用技术相匹配的传输介质——多芯光纤和少模光纤(few-mode fiber, FMF)备受瞩目,其中FMF与现有的单模光纤使用方式基本兼容,所以FMF有可能为光通信带来跨越式的发展。FMF是一种纤芯面积足够大、足以利用几个独立的空间模式传输并行数据的光纤。理想情况下,FMF的容量与模式的数量成正比,然而,为了延长传输距离,需要使用有源FMF制作放大器,来增强衰减的信号。2011年,Bai等人首次对掺铒FMF放大器进行研究,测试了不同抽运模式下LP01、LP11两模式的增益均衡情况 [76] ,后来他们将此双模掺铒FMF放大器成功应用于50 km的传输系统,实现了26.4 Tb/s的传输实验 [77] ;2013年,Jung等人制作了环形掺铒FMF,验证了该光纤可实现22 dB双模增益 [78] 。

5. 有源光纤的应用

利用有源光纤作为增益介质来制作光纤激光器具有较大的优势,例如光束质量好、能量转换效率高、重量轻、免维护、可风冷、结构紧凑及成本低等。光纤激光器应用于激光加工系统,具有加工精度高、加工速度快、使用寿命长和柔性好等优点,因此稀土掺杂光纤激光器已经在许多方面取代了传统的气体和固体激光器。而作为光纤激光器增益介质的有源光纤,对激光器的特性具有决定性的作用。

单频光纤激光器:2003年,NP Photonics公司的Spiegelberg等人利用2 cm长的高浓度Er3+/Yb3+共掺磷酸盐光纤作为增益介质,搭建了波长为1550 nm的DBR型单频激光器,首次实现了超过100 mW的功率输出,有源光纤的增益系数高达5 dB/cm [79] ;2010年,华南理工大学杨忠民课题组将Er3+/Yb3+共掺磷酸盐光纤的增益系数提高到了5.2 dB/cm,并依此实现了超过300 mW的DBR型单频光纤激光器 [80] ;之后该课题组又相继报道了基于高掺Yb3+磷酸盐光纤(增益系数为5.7 dB/cm)和高掺Tm3+锗酸盐光纤(增益系数为2.3 dB/cm)的短腔型百毫瓦级单频光纤激光器 [81] [82] 。

高功率激光器:2010年,IPG公司利用镱离子的优势,制作了10 kW的高功率单模掺镱光纤激光器,在当时是功率最高的;2012年,Xiao等人利用高质量的掺镱有源光纤作为增益介质,设计了波长为1080 nm的高功率全光纤单模激光器,实现了1 kW的连续输出,斜效率为71% [83] ;中国工程物理研究院激光聚变研究中心的研究人员经过三年科研攻关,于2016年,成功研制出纤芯30 μm/包层900 μm的掺镱铝磷硅(Yb-APS)三元体系有源光纤,实现了6.03 kW的高功率输出,并且在5 kW功率水平可长期稳定工作 [84] 。

脉冲激光器:2006年,Chong等人演示了全正常色散的掺镱光纤锁模激光器,实现了脉冲能量为3 μJ的170 fs短脉冲激光 [85] ;Antipov等为了克服掺铒的氟化物光纤产生的2.8 μm的激光容易被水吸收的问题,利用掺钬光纤作为增益介质,在近2.9 μm处演示了超快锁模飞秒激光,脉冲宽度为180 fs,峰值功率高达37 kW [86] 。

高能量激光器:Wan等人利用掺铥的有源光纤作为增益介质,设计了高能量飞秒光纤激光器,并获得了36.7 μJ、2.5 MHz、910 fs的脉冲 [87] ;之后他们在2015年又报道了3 μm中红外高能量超快ZBLAN光纤激光器,并利用掺铒的ZBLAN光纤制作了放大器,实现了脉冲能量为12.4 μJ、重复频率为100 kHz、103 fs的脉冲 [88] 。

近年还发现,利用有源光纤制作传感器,可扩大应用范围、减少系统的复杂性、缩小传感器的体积和提高精度,特别是在一些极端条件下,有源光纤传感器起到了很好的补充作用。2002年,Lai等人报道了利用铒镱共掺的有源光纤和光纤光栅制作的传感器,可同时测量温度和张力,使用有源光纤可很好地满足温度响应率高和传感器尺寸小的要求 [89] 。2014年,Kevin等人在高掺铒光纤上刻写再生型光纤Bragg光栅,利用该高掺杂光纤光栅来测量不同温度下N2的流速,并利用掺铒光纤放大器作为泵浦源和信号源。实验结果表明,该传感器可以在800℃下测量0.066~0.66 m/s低流速氮气的流量 [90] 。暨南大学报道了有源光纤氢传感器,利用铒镱共掺的有源光纤加热镀在表面的金属薄膜,使金属薄膜的温度达到常温,来提升其吸氢活性,在低温条件下实现氢气浓度的测量 [91] 。2017年,Liu等人设计了一种新颖的少模–单模–少模结构的掺铒光纤环形腔激光传感器,该传感器可实现高分辨率和高精度的折射率测量 [92] 。

6. 展望

目前,无论是普通的有源光纤还是光子晶体有源光纤,主要使用石英为基底材料。虽然利用气相沉积工艺制作的稀土掺杂的石英光纤的损耗很低,且机械、力学和化学性能都比较好,成本也低,但是由于制备工艺和石英本身的限制,导致稀土掺杂浓度不高,光谱透过范围有限,最终也限制了使用范围。另外,利用稀土掺杂的有源光纤制作的激光器种类很多,而且也获得了较高的输出功率、较好的光斑质量和多种波长的激光输出,但目前高功率激光的稳定性仍需提高,而且像紫外激光、红外激光、白激光等激光器的性能都有一定的欠缺,这与有源光纤的质量、损耗、耦合效率、稀土掺杂浓度、基质材料和制作工艺等因素有关。所以,继续探索新的制备工艺及新的基质材料来制备更低损耗、无光子暗化效应、高浓度掺杂、新型结构的高质量有源光纤十分必要。

文章引用

张炳涛,陈月娥,赵兹罡,王 勇. 有源光纤的进展与应用

Progress and Applications of Active Optical Fibers[J]. 应用物理, 2018, 08(05): 256-268. https://doi.org/10.12677/APP.2018.85032

参考文献

- 1. Liu, X.M., Yang, X.F., Lu, F.Y., et al. (2005) Stable and Uniform Dual-Wavelength Erbium-Doped Fiber Laser Based on Fiber Bragg Gratings and Photonic Crystal Fiber. Optics Express, 13, 142-147. https://doi.org/10.1364/OPEX.13.000142

- 2. Ramaswami, R. (2002) Optical Fiber Communication: From Transmission to Networking. IEEE Communications Magazine, 40, 138-147. https://doi.org/10.1109/MCOM.2002.1006983

- 3. Kapoor, V., Subach, F.V., Kozlov, V.G., et al. (2007) New Lasers for Flow Cytometry: Filling the Gaps .Nature Methods, 4, 678-679. https://doi.org/10.1038/nmeth0907-678

- 4. Tabassum, S., Kumar, R. and Dong, L. (2017) Nanopatterned Optical Fiber Tip for Guided Mode Resonance and Application to Gas Sensing. IEEE Sensors Journal, 17, 7262-7272. https://doi.org/10.1109/JSEN.2017.2748593

- 5. Wu, C.W., Kuo, C.Y., Lin, J.W., et al. (2017) Application of a WGM Optical Fiber Probe Fabricated by 3D Printing Technology for Glucose Concentration Measurement. Optical and Quantum Electronics, 49, 29. https://doi.org/10.1007/s11082-016-0842-1

- 6. 廖延彪, 苑立波, 田芊. 中国光纤传感40年[J]. 光学学报, 2018, 38(3): 1-29.

- 7. Fu, L.B., Ibsen, M., Richardson, D.J., et al. (2005) Compact High-Power Tunable Three-Level Operation of Double Clad-ding Nd-Doped Fiber Laser. IEEE Photonics Technology Letters, 17, 306-308. https://doi.org/10.1109/LPT.2004.840034

- 8. Murakami, M., Fujimoto, Y., Motokoshi, S., et al. (2014) Short-Length Fiber Laser Oscillation in 4-mm Nd-Doped Silica Fiber Fabricated by Zeolite Method. Optics Communications, 328, 121-123. https://doi.org/10.1016/j.optcom.2014.04.074

- 9. Swiderski, J., Zajac, A., Skorczakowski, M., et al. (2005) Q-Switched Nd-Doped Double-Clad Fiber Laser. Opto-Electronics Review, 13, 187-191.

- 10. Htein, L., Fan, W., Watekar, P.R., et al. (2013) Am-plification at 1400 - 1450 nm of the Large-Core Nd-Doped Fiber by White LED Pumping. IEEE Photonics Technology Letters, 25, 1081-1083. https://doi.org/10.1109/LPT.2013.2259587

- 11. Wang, L.F., He, D.B., Feng, S.Y., et al. (2015) Heavily Yb-Doped Phosphate Large-Mode Area All-Solid Photonic Crystal Fiber Operating at 990 nm. Laser Physics Letters, 12, 5. https://doi.org/10.1088/1612-2011/12/7/075102

- 12. Wang, J.H., Chen, G., Zhang, L., et al. (2012) High-Efficiency Fiber Laser at 1018 nm Using Yb-Doped Phosphosilicate Fiber. Applied Optics, 51, 7130-7133. https://doi.org/10.1364/AO.51.007130

- 13. Gao, C., Huang, Z.H., Wang, Y.Y., et al. (2016) Yb-Doped Aluminophosphosilicate Laser Fiber. Journal of Lightwave Technology, 34, 5170-5174. https://doi.org/10.1109/JLT.2016.2602372

- 14. Liao, L., Wang, Y.B., Xing, Y.B., et al. (2015) Fabrication, Measurement, and Application of 20/400 Yb-Doped Fiber. Applied Optics, 54, 6516-6520. https://doi.org/10.1364/AO.54.006516

- 15. Watekar, P.R., Goswami, M.L.N., Biswas, J.C., et al. (2004) Simultaneous Com-pensation of Dispersion and Losses Using Er-Doped Double-Core Optical Fiber. Optical and Quantum Electronics, 36, 405-411. https://doi.org/10.1023/B:OQEL.0000022944.70200.65

- 16. Newburgh, G.A., Zhang, J. and Dubinskii, M. (2007) Tm-Doped Fiber Laser Resonantly Diode-Cladding-Pumped at 1620 nm. Laser Physics Letters, 14, Article ID: 125101. https://doi.org/10.1088/1612-202X/aa8b80

- 17. Xia, C.M., Zhou, G.Y., Liu, J.T., et al. (2015) Optical and Laser Properties of Tm3+-Doped Air-Cladding Fiber Fabricated by Plasma Non-Chemical Vapor Deposition. Applied Physics B-Lasers and Optics, 121, 25-30. https://doi.org/10.1007/s00340-015-6197-7

- 18. Zhu, X.S., Zong, J., Miller, A., et al. (2012) Single-Frequency Ho3+-Doped ZBLAN Fiber Laser at 1200 nm. Optics Letters, 37, 4185-4187. https://doi.org/10.1364/OL.37.004185

- 19. Jackson, S.D. and Mossman, S. (2003) Diode-Cladding-Pumped Yb3+, Ho3+-Doped Silica Fiber Laser Operating at 2.1-μm. Applied Optics, 42, 3546-3549. https://doi.org/10.1364/AO.42.003546

- 20. Liu, X.Q., Kuan, P.W., Li, D.H., et al. (2016) Heavily Ho3+-Doped Lead Silicate Glass Fiber for Similar to 2 μm Fiber Lasers. Optical Materials Express, 6, 1093-1098. https://doi.org/10.1364/OME.6.001093

- 21. Tang, G., Yang, Z., Luo, L., et al. (2008) Dy3+-Doped Chalcohalide Glass for 1.3-μm Optical Fiber Amplifiers. Journal of Materials Research, 23, 954-961. https://doi.org/10.1557/jmr.2008.0139

- 22. Park, B.J., Seo, H.S., Ahn, J.T., et al. (2008) Dy3+-Doped Ge-As-S Fiber for 2.96 μm Fiber Laser. IEEE Conference on Opto-Electronics & Communications Conference, Australian, 7-10 July 2008, 1-2.

- 23. Baney, D.M., Rankin, G. and Chang, K.W. (1996) Blue Pr3+-Doped ZBLAN Fiber Upconversion Laser. Optics Letters, 21, 1372-1374. https://doi.org/10.1364/OL.21.001372

- 24. Nakanishi, J., Yamada, T., Murakami, M., et al. (2013) Watt-Order Direct Green Laser Oscillation at 522nm in Pr3+-Doped Waterproof Fluoro-Aluminate-Glass Fiber. Conference on Lasers and Electro-Optics, San Jose, 9-14 June 2013, JTu4A.02. https://doi.org/10.1364/CLEO_AT.2013.JTu4A.02

- 25. Nakanishi, J., Yamada, T., Fujitomo, Y., et al. (2011) High Power Red Laser Oscillation in Pr3+-Doped Waterproof Fluoro-Aluminate Glass Fiber Excited by a GaN Laser Diode. Solid State Lasers Xx: Technology and Devices, 7912, 1285-1286.

- 26. Sojka, L., Tang, Z., Furniss, D., et al. (2014) Broad-band, Mid-Infrared Emission from Pr3+Doped GeAsGaSe Chalcogenide Fiber, Optically Clad. Optical Materials, 36, 1076-1082. https://doi.org/10.1016/j.optmat.2014.01.038

- 27. Leconte, B., Cadier, B., Gilles, H., et al. (2015) Extended Tunability of Nd-Doped Fiber Lasers Operating at 872-936 nm. Optics Letters, 40, 4098-4101. https://doi.org/10.1364/OL.40.004098

- 28. Tang, Y.L., Yang, Y. and Xu, J.Q. (2008) Side-Pumped Short Rectangular Nd-Doped Phosphate Glass Fiber Lasers. Chinese Optics Letters, 6, 583-585. https://doi.org/10.3788/COL20080608.0583

- 29. Zhang, G., Luo, F.F., Liu, X.F., et al. (2010) Nd-Doped Phosphate Glass Mi-crostructured Optical Fiber Laser. Laser Physics, 20, 1425-1427. https://doi.org/10.1134/S1054660X10110344

- 30. Wang, L.F., He, D.B., Yu, C.L., et al. (2018) Compact Single-Mode Nd-Doped Silicate Glass Multitrench Fiber with 40 μm Core Diameter. IEEE Journal of Selected Topics in Quantum Electronics, 24, 4. https://doi.org/10.1109/JSTQE.2017.2655267

- 31. Saha, M., Das Chowdhury, S., Shekhar, N.K., et al. (2016) Yb-Doped Ped-estal Silica Fiber through Vapor Phase Doping for Pulsed Laser Applications. IEEE Photonics Technology Letters, 28, 1022-1025. https://doi.org/10.1109/LPT.2016.2524040

- 32. Wang, L.F., He, D.B., Zhang, L., et al. (2017) 5 W Output Power from a Dou-ble-Clad Hybrid Fiber with Yb-Doped Phosphate Core and Silicate Cladding. Optics Letters, 42, 3008-3011. https://doi.org/10.1364/OL.42.003008

- 33. Aleshkina, S.S., Levchenko, A.E., Medvedkov, O.I., et al. (2018) Photodarken-ing-Free Yb-Doped Saddle-Shaped Fiber for High Power Single-Mode 976-nm Laser. IEEE Photonics Technology Letters, 30, 127-130. https://doi.org/10.1109/LPT.2017.2778305

- 34. Li, J., Wang, J., Liu, P., et al. (2009) Design and Fabrication of an Er-Doped Silica Optical Fiber with Six Photosensitive Subcores. Chinese Physics Letters, 26, 3.

- 35. Kuhn, V., Kracht, D., Neumann, J., et al. (2011) Er-Doped Photonic Crystal Fiber Amplifier with 70 W of Output Power. Optics Letters, 36, 3030-3032. https://doi.org/10.1364/OL.36.003030

- 36. Nicholson, J.W., Desantolo, A., Kaenders, W., et al. (2006) Self-Frequency-Shifted Solitons in a Polarization-Maintaining, Very-Large-Mode Area, Er-Doped Fiber Amplifier.Optics Express, 24, 23396-23402. https://doi.org/10.1364/OE.24.023396

- 37. Nicholson, J.W., Ahmad, R., DeSantolo, A., et al. (2017) High Average Power, 10 GHz Pulses from a Very-Large-Mode-Area, Er-Doped Fiber Amplifier. Journal of the Optical Society of America B-Optical Physics, 34, A1-A6. https://doi.org/10.1364/JOSAB.34.0000A1

- 38. Egorova, O.N., Semjonov, S.L., Velmiskin, V.V., et al. (2014) Phosphate-Core Silica-Clad Er/Yb-Doped Optical Fiber and Cladding Pumped Laser. Optics Express, 22, 7632-7637. https://doi.org/10.1364/OE.22.007632

- 39. Ouyang, D.Q., Guo, C.Y., Ruan, S.C., et al. (2014) Optimized Flat Supercontinuum Generation in High Nonlinear Fibers Pumped by a Nanosecond Er/Yb Co-Doped Fiber Amplifier. Laser Physics, 24, 6. https://doi.org/10.1088/1054-660X/24/4/045104

- 40. Ouyang, D.Q., Guo, C.Y., Ruan, S.C., et al. (2014) Yb Band Parasitic Lasing Suppression in Er/Yb-Co-Doped Pulsed Fiber Amplifier Based on All-Solid Photonic Bandgap Fiber. Applied Physics B-Lasers and Optics, 114, 585-590. https://doi.org/10.1007/s00340-013-5564-5

- 41. Gurram, S., Kuruvilla, A., Singh, R., et al. (2017) Generation of 6.8 W of CW Output Power at 1550 nm Using Small Mode Field Diameter Er: Yb Co-Doped Double Clad Fiber in Laser Oscillator Configuration. Laser Physics, 27, 5.

- 42. Eichhorn, M. (2005) High-Peak-Power Tm-Doped Double-Clad Fluoride Fiber Amplifier. Optics Letters, 30, 3329-3331. https://doi.org/10.1364/OL.30.003329

- 43. Geng, J.H., Wang, Q., Luo, T., et al. (2009) Single-Frequency Narrow-Linewidth Tm-Doped Fiber Laser Using Silicate Glass Fiber. Optics Letters, 34, 3493-3495. https://doi.org/10.1364/OL.34.003493

- 44. Shi, W., Petersen, E.B., Nguyen, D.T., et al. (2011) 220 μJ Monolithic Single-Frequency Q-Switched Fiber Laser at 2 μm by Using Highly Tm-Doped Germanate Fibers. Optics Letters, 36, 3575-3577. https://doi.org/10.1364/OL.36.003575

- 45. Xu, R.R., Tian, Y., Hu, L.L., et al. (2011) 2 μm Spectroscopic Investigation of Tm3+-Doped Tellurite Glass Fiber. Journal of Non-Crystalline Solids, 357, 2489-2493. https://doi.org/10.1016/j.jnoncrysol.2010.11.059

- 46. Kuan, P.W., Li, K.F., Zhang, G., et al. (2013) Compact Broadband Ampli-fied Spontaneous Emission in Tm3+-Doped Tungsten Tellurite Glass Double-Cladding Single-Mode Fiber. Optical Materials Express, 3, 723-728. https://doi.org/10.1364/OME.3.000723

- 47. Coscelli, E., Molardi, C., Cucinotta, A., et al. (2014) Symmetry-Free Tm-Doped Photonic Crystal Fiber with Enhanced Mode Area. IEEE Journal of Selected Topics in Quantum Electronics, 20, 544-550. https://doi.org/10.1109/JSTQE.2014.2299636

- 48. Watekar, P.R., Ju, S. and Han, W.T. (2006) 800-nm Upconversion Emission in Yb-Sensitized Tm-Doped Optical Fiber. IEEE Photonics Technology Letters, 18, 1609-1611. https://doi.org/10.1109/LPT.2006.879584

- 49. Lee, Y.W., Ling, H.Y., Lin, Y.H., et al. (2015) Heavily Tm3+-Doped Silicate Fi-ber with High Gain Per Unit Length. Optical Materials Express, 5, 549-557. https://doi.org/10.1364/OME.5.000549

- 50. Wen, X., Tang, G.W., Yang, Q., et al. (2016) Highly Tm3+-Doped Germanate Glass and Its Single Mode Fiber for 2.0 μm Laser. Scientific Reports, 6, 10. https://doi.org/10.1038/srep20344

- 51. Jackson, S.D. (2006) The Effects of Energy Transfer Upconversion on the Performance of Tm3+, Ho3+-Doped Silica Fiber Lasers. IEEE Photonics Technology Letters, 18, 1885-1887. https://doi.org/10.1109/LPT.2006.881686

- 52. Watekar, P.R., Ju, S. and Han, W.T. (2008) Optical Properties of Ho-Doped Alumino-Germano-Silica Glass Optical Fiber. Journal of Non-Crystalline Solids, 354, 1453-1459. https://doi.org/10.1016/j.jnoncrysol.2007.08.068

- 53. Li, D.H., Xu, W.B., Kuan, P.W., et al. (2016) Spectroscopic and Laser Properties of Ho3+-Doped Lanthanum-Tungsten-Tellurite Glass and Fiber. Ceramics International, 42, 10493-10497. https://doi.org/10.1016/j.ceramint.2016.03.076

- 54. Tsang, Y.H. and El-Taher, A.E. (2011) Efficient Lasing at near 3 μm by a Dy-Doped ZBLAN Fiber Laser Pumped at Similar to 1.1 μm by an Yb Fiber Laser. Laser Physics Letters, 8, 818-822. https://doi.org/10.1002/lapl.201110068

- 55. Acioli, L.H., Gomes, A.S.L., deAraujo, C.B., et al. (1996) Infrared-to-Blue Fre-quency Upconversion in a Pr3+-Doped Silicate Fiber. Physical Review B, 54, 9126-9130. https://doi.org/10.1103/PhysRevB.54.9126

- 56. Poole, S., Payne, D., Mears, R., et al. (1986) Fabrication and Characterization of Low-Loss Optical Fibers Containing Rare-Earth Ions. Journal of Lightwave Technology, 4, 870-876. https://doi.org/10.1109/JLT.1986.1074811

- 57. Wang, H.H., Tu, F., Li, J., et al. (2008) Effect of Temperature and Bending on PANDA Polarization-Maintaining Fibers Fabricated by PCVD Method. IEEE Photonicsglobal, Singapore, 8-11 December 2008, 1-4. https://doi.org/10.1109/IPGC.2008.4781456

- 58. Choi, S.-S., Cho, H.-S., Koo, S.-S., et al. (2009) Fabrication and Characteris-tics Evaluation of Panda Polarization-Maintaining Optical Fibers with B2O3 SAP’s by VAD Method. 14th Optoelectronics and Com-munications Conference, Vienna, 13-17 July 2009, 1-2.

- 59. Wang, S., Xu, W., Lou, F., et al. (2016) Spectroscopic and Laser Proper-ties of Al-P Co-Doped Yb Silica Fiber Core-Glass Rod and Large Mode Area Fiber Prepared by Sol-Gel Method. Optical Materials Express, 6, 69-78. https://doi.org/10.1364/OME.6.000069

- 60. Webb, A.S., Boyland, A.J., Standish, R.J., et al. (2010) MCVD in-Situ Solution Doping Process for the Fabrication of Complex Design Large Core Rare-Earth Doped Fibers. Journal of Non-Crystalline Solids, 356, 848-851. https://doi.org/10.1016/j.jnoncrysol.2010.01.008

- 61. Paul, M.C., Kir’yanov, A.V., Das, S., et al. (2010) Development of Large-Core Yb2O3-Doped Yttria-Alumino-Silicate Nano-Particles Based Optical Fibers. 2nd Workshop on Specialty Optical Fibers and Their Applications, Oaxaca, 14 October 2010, 78391Y-1-4.

- 62. Kurkov, A.S., Sholokhov, E.M., Medvedkov, O.I., et al. (2009) Holmium Fiber Laser Based on the Heavily Doped Active Fiber. Laser Physics Letters, 6, 661-664. https://doi.org/10.1002/lapl.200910056

- 63. Liu, H.G., Huang, J.H., Li, J.H., et al. (2013) Above 100 nJ All-Normal-Dispersion Femtosecond Pulse Generation from a Large-Core Multi-Mode Fiber Laser. Laser Physics Letters, 10, Article ID: 055101. https://doi.org/10.1088/1612-2011/10/5/055101

- 64. Lizarraga, N., Puente, N.P., Chaikina, E.I., et al. (2009) Single-Mode Er-Doped Fiber Random Laser with Distributed Bragg Grating Feedback. Optics Express, 17, 395-404. https://doi.org/10.1364/OE.17.000395

- 65. Swiderski, J. and Michalska, M. (2013) Mid-Infrared Supercontinuum Generation in a Single-Mode Thulium-Doped Fiber Amplifier. Laser Physics Letters, 10, 6. https://doi.org/10.1088/1612-2011/10/3/035105

- 66. Wang, W.L., Huang, L.J., Leng, J.Y., et al. (2015) 2 kW CW near Single Mode All-Fiber Ytterbium-Doped Fiber Laser. Optik, 126, 1712-1715. https://doi.org/10.1016/j.ijleo.2015.05.009

- 67. Beier, F., Hupel, C., Kuhn, S., et al. (2017) Single Mode 4.3 kW Output Power from a Diode-Pumped Yb-Doped Fiber Amplifier. Optics Ex-press, 25, 14892-14899. https://doi.org/10.1364/OE.25.014892

- 68. Shi, G.N., Fu, S.J., Sheng, Q., et al. (2018) Mega-watt-Peak-Power Picosecond All-Fiber-Based Laser in MOPA Using Highly Yb3+-Doped LMA Phosphate Fiber. Optics Communica-tions, 411, 133-137. https://doi.org/10.1016/j.optcom.2017.11.026

- 69. Glas, P., Fischer, D., Moenster, M., et al. (2005) Large-Mode-Area Nd-Doped Single-Transverse-Mode Dual-Wavelength Microstructure Fiber Laser. Optics Express, 13, 7884-7892. https://doi.org/10.1364/OPEX.13.007884

- 70. Richardson, D.J., Britton, P. and Taverner, D. (1997) Diode-Pumped, High-Energy, Single Transverse Mode Q-Switch Fibre Laser. Electronics Letters, 33, 1955-1956. https://doi.org/10.1049/el:19971325

- 71. Peng, K., Zhan, H., Ni, L., et al. (2016) Single-Mode Large-Mode-Area Laser Fiber with Ultralow Numerical Aperture and High Beam Quality. Applied Optics, 55, 10133-10137. https://doi.org/10.1364/AO.55.010133

- 72. 林桢. 新型大模场直径弯曲不敏感单模及少模光纤的研究[D]: [博士学位论文]. 北京: 北京交通大学, 2014.

- 73. Yehouessi, J.P., Vanvincq, O., Cassez, A., et al. (2016) Extreme Large Mode Area in Single-Mode Pixelated Bragg Fiber. Optics Express, 24, 4761-4770. https://doi.org/10.1364/OE.24.004761

- 74. Iizawa, K., Varshney, S.K., Tsuchida, Y., et al. (2008) Bend-Insensitive Lasing Characteristics of Single-Mode, Large-Mode-Area Ytterbium-Doped Photonic Crystal Fiber. Optics Express, 16, 579-591. https://doi.org/10.1364/OE.16.000579

- 75. Li, W.T., Chen, D.P., Zhou, Q.L., et al. (2015) Large-Mode-Area Sin-gle-Mode-Output Neodymium-Doped Silicate Glass All-Solid Photonic Crystal Fiber. Scientific Reports, 5, Article No. 12547. https://doi.org/10.1038/srep12547

- 76. Bai, N., Ip, E., Wang, T., et al. (2011) Multimode Fiber Amplifier with Tunable Modal Gain Using a Reconfigurable Multimode Pump. Optics Express, 19, 16601-16611. https://doi.org/10.1364/OE.19.016601

- 77. Bai, N., Ip, E., Huang, Y.K., et al. (2012) Mode-Division Multiplexed Transmission with Inline Few-Mode Fiber Amplifier. Optics Express, 20, 2668-2680. https://doi.org/10.1364/OE.20.002668

- 78. Jung, Y., Kang, Q., Sleiffer, V.A., et al. (2013) Three Mode Er3+Ring-Doped Fiber Amplifier for Mode-Division Multiplexed Transmission. Optics Express, 21, Article No. 10383. https://doi.org/10.1364/OE.21.010383

- 79. Spiegelberg, C.P., Geng, Y., Hu, Y., et al. (2003) Compact 100 mW Fiber Laser with 2 kHz Linewidth. Optical Fiber Communication Conference, Atlanta, 23 March 2003, PD45-P1-3. https://doi.org/10.1109/OFC.2003.316027

- 80. Xu, S.H., Yang, Z.M., Liu, T., et al. (2010) An Efficient Compact 300 mW Narrow-Linewidth Single Frequency Fiber Laser at 1.5 μm. Optics Express, 18, 1249-1254. https://doi.org/10.1364/OE.18.001249

- 81. Xu, S., Yang, Z., Zhang, W., et al. (2011) 400 mW Ultrashort Cavity Low-Noise Single-Frequency Yb³⁺-Doped Phosphate Fiber Laser. Optics Letters, 36, 3708-3710. https://doi.org/10.1364/OL.36.003708

- 82. Qi, Y., Shanhui, X., Chan, L., et al. (2015) A Single-Frequency Linearly Polarized Fiber Laser Using a Newly Developed Heavily Tm3+-Doped Germanate Glass Fiber at 1.95 μm. Chinese Physics Letters, 32, 62-65.

- 83. Xiao, Y., Brunet, F., Kanskar, M., et al. (2012) 1-kilowatt CW All-Fiber Laser Oscillator Pumped with Wave-length-Beam-Combined Diode Stacks. Optics Express, 20, 3296-3301. https://doi.org/10.1364/OE.20.003296

- 84. Aoxiang, L., Xuan, T., Huan, Z., et al. (2016) 6kW Yb-Doped Aluminophosphosilicate Laser Fiber. High Power Laser And Particle Beams, 28, 168-168.

- 85. Chong, A., Buckley, J., Renninger, W., et al. (2006) All-Normal-Dispersion Femtosecond Fiber Laser. Optics Express, 14, 10095-10100. https://doi.org/10.1364/OE.14.010095

- 86. Antipov, S., Hudson, D.D., Fuerbach, A., et al. (2016) High-Power Mid-Infrared Femtosecond Fiber Laser in the Water Vapor Transmission Window. Optica, 3, 1373-1376. https://doi.org/10.1364/OPTICA.3.001373

- 87. Wan, P., Yang, L.M. and Liu, J. (2013) High Pulse Energy 2 μm Femtosecond Fiber Laser. Optics Express, 21, 1798-1803. https://doi.org/10.1364/OE.21.001798

- 88. Wan, P., Yang, L.M., Bai, S., et al. (2015) High Energy 3 μm Ultrafast Pulsed Fiber Laser. Optics Express, 23, 9527-9532. https://doi.org/10.1364/OE.23.009527

- 89. Lai, Y.C., Qiu, G.F., Zhang, W., et al. (2002) Amplified Spontaneous Emis-sion-Based Technique for Simultaneous Measurement of Temperature and Strain by Combining Active Fiber with Fiber Gratings. Re-view of Scientific Instruments, 73, 3369-3372. https://doi.org/10.1063/1.1499758

- 90. Chen, R., Yan, A., Wang, Q., et al. (2014) Fiber-Optic Flow Sensors for High-Temperature Environment Operation up to 800 ˚C. Optics Letters, 39, 3966-3938. https://doi.org/10.1364/OL.39.003966

- 91. Yu, Z.P., Jin, L., Chen, L.J., et al. (2015) Microfiber Bragg Grating Hydrogen Sen-sors. IEEE Photonics Technology Letters, 27, 2575-2578. https://doi.org/10.1109/LPT.2015.2478445

- 92. Liu, J.X., Wang, M.G., Liang, X., et al. (2017) Erbium-Doped Fiber Ring Laser Based on Few-Mode-Single- mode-Few-Mode Fiber Structure for Refractive Index Measurement. Optics and Laser Technology, 93, 74-78. https://doi.org/10.1016/j.optlastec.2017.02.008

NOTES

*通讯作者。