Hans Journal of Chemical Engineering and Technology

Vol.

11

No.

04

(

2021

), Article ID:

43593

,

11

pages

10.12677/HJCET.2021.114026

管壳式换热器中高黏流体传热强化进展

汪健清1,施金玲2,施龙生2,王嘉骏1*,冯连芳1

1浙江大学化学工程与生物工程学院化学工程联合国家重点实验室,浙江 杭州

2启东市巨龙石油化工装备有限公司,江苏 启东

收稿日期:2021年5月17日;录用日期:2021年6月23日;发布日期:2021年6月30日

摘要

管壳式换热器是目前工业上应用最广泛的换热器类型之一。本文综述了管壳式换热器中高黏流体传热过程强化技术的研究进展,分析了各种传热强化技术的优势与不足。针对高黏流体在管程与壳程内呈层流或过渡流,在传热面处流速慢、扰动弱,传热过程存在传热效率低、传热不均等问题,指出减薄层流热边界层厚度或破坏其发展及增强径向流动混合是强化高黏流体传热的关键。使用管内插入物、对换热管进行螺旋、弯曲及紧凑排列或使用高效的折流板有利于减薄层流边界层厚度,强化径向混合,进而提升传热性能。但在有效提升传热性能的同时也会显著增加流动阻力,难以有效提升换热器的综合性能。高传热与低流阻特性兼备的高黏流体传热强化技术是研究的主要方向,同时向换热器结构简单化与综合性能更优化的方向发展。

关键词

管壳式换热器,传热强化,高黏流体,层流

Heat Transfer Enhancement Techniques for High-Viscosity Fluid in Shell-and-Tube Heat Exchanger

Jianqing Wang1, Jinling Shi2, Longsheng Shi2, Jiajun Wang1*, Lianfang Feng1

1State Key Laboratory of Chemical Engineering, College of Chemical and Biological Engineering, Zhejiang University, Hangzhou Zhejiang

2Qidong Julong Petrochemical Equipment Co., Ltd., Qidong Jiangsu

Received: May 17th, 2021; accepted: Jun. 23rd, 2021; published: Jun. 30th, 2021

ABSTRACT

The shell-and-tube heat exchanger is one of the most widely used heat exchangers in industry. The research progress of heat transfer enhancement techniques for high-viscosity fluid in shell-and-tube heat exchanger was reviewed. The advantages and disadvantages of various techniques were analyzed. The high-viscosity fluid presents laminar or transitional flow patterns in the tube side and the shell side. The small flow velocity close to the heat transfer surfaces and the weak flow disturbance lead to low efficiency and inhomogeneity of heat transfer. It is pointed out that thinning the thickness of thermal boundary layer or destroying its development, and strengthening the radial mixing are the keys to the heat transfer enhancement of high-viscosity fluid. The application of tube inserts, compactly arranged tubes or efficient baffles can reduce the thickness of the laminar boundary layer, strengthen the radial mixing and then improve the heat transfer performance. However, when the heat transfer performance is improved, the flow resistance significantly increases, which limits the improvement for the overall performance of heat exchangers. Therefore, the technique with high heat transfer performance and low flow resistance is the main research direction of heat transfer enhancement for high-viscosity fluid. Additionally, simplified structure and better comprehensive performance are the development trend of the shell-and-tube heat exchangers.

Keywords:Shell-and-Tube Heat Exchanger, Heat Transfer Enhancement, High-Viscosity Fluid, Laminar Flow

Copyright © 2021 by author(s) and Hans Publishers Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY 4.0).

http://creativecommons.org/licenses/by/4.0/

1. 引言

在换热设备中,管壳式换热器具有结构简单,维护方便,耐高温高压等优点,在工业上得到了广泛应用。低黏流体在管壳式换热器中能通过湍流机制有效提高换热效率,而对于高黏流体,由于黏度大、操作雷诺数低,流体处于层流或过渡流域,在对流传热过程中普遍存在着传热系数低、传热不均匀以及功耗大等缺点。因而探索高效的高黏流体传热过程强化方法有着重要的意义。本文分别从管程强化传热方法、壳程强化传热方法以及复合强化方法三个角度对目前管壳式换热器强化传热技术的研究进展进行综述,分析各方法针对高黏流体传热过程存在的优势与不足,并指出研究的重点与方向,为管壳式换热器中高黏流体的传热强化研究提供一定的理论基础。

2. 管程强化传热

高黏流体在管道中呈层流或过渡流态,在耦合传热的情况下,在流动截面上存在速度与温度梯度。对高黏流体的传热强化必须增加近壁区流体的扰动、减薄近壁处热边界层厚度或破坏其发展,并使流体产生径向流动混合。管程的传热强化主要包括两个方面:一是通过机械加工开发出的异形强化传热管;二是在管内加入内插物。

2.1. 异形强化传热管

异形强化传热管主要通过增强壁面处扰动,减薄层流底层的厚度来强化传热和降低热阻,目前已开发出多种异形强化传热管如波纹管、螺旋槽管、横纹槽管、扭曲椭圆管等。研究表明,相比于普通直管,异形管能获得较小的场协同角 [1] (速度与温度梯度的夹角),即能够提高速度与温度梯度的协同程度,提高传热性能,在强化层流传热方面具有一定潜力,但摩擦损失也会显著提高 [2] [3]。一些学者研究了低雷诺数下异形管内的流动与传热特性,如Du等 [4] 研究了新型正弦型槽结构换热管内的流动与传热特性(400 < Re < 1800),发现相比于直管,正弦型槽结构具有较小的场协同角,使得传热速率能提高4.89倍,而摩擦损失提高了5.62倍。Cheng等 [5] 采用数值模拟方法研究了椭圆扭曲管在低雷诺数Re = 50~2000范围内的传热特性,发现由于二次流的形成,减小了协同角,提升了传热性能。

2.2. 管内插入物

在研究与应用中,异形管对低黏流体(如空气和水)的强化作用明显,但对高黏流体,尤其是像聚合物熔体这种高黏流体,作用则相对有限。这是因为管粗糙度或外形的变化对管中心处高黏流体影响很小,无法引起有效的径向流动混合。管内插入物能改变近壁区流体的流动行为,破坏热边界层发展,并使流体发生径向流动混合,达到增强管内高黏流体混合与传热的目的。一些管内插入物如图1所示。

Figure 1. Tube inserts

图1. 管内插入物

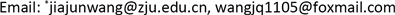

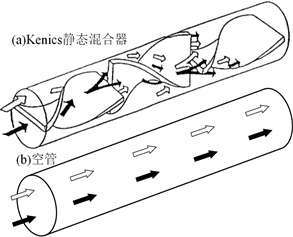

Figure 2. Fluid flow behavior in Kenics static mixer and empty tube

图2. 流体在Kenics静态混合器与空管内的流动行为

其中,Kenics和SMX是静态混合器中较典型且研究较多的两种。以Kenics静态混合器为例,与普通空管不同,高黏流体在Kenics静态混合器中呈现周期性剪切流动,通过不断地剪切、分流、混合以获得较好的混合效果与传热性能,如图2所示。这使得Kenics静态混合器在层流域可显著提高混合效率和传热性能 [6] [7],在工业中也得到了广泛应用。

纽带式插入物能使得流体不断发生转动,从而强化混合与传热。图3为流体在具有不同数量纽带和同向、反向两种方向放置情况下的管内流动机理示意图 [8]。可以发现,相比于单根纽带,插入多根纽带能形成多个涡流区和回流区;相比于同向旋转放置,反向旋转放置的部分回流变成撞击流,能进一步强化混合和传热,但流动阻力会显著增加 [9] [10]。Li等 [11] 采用数值模拟方法研究了空心纽带插入物在Re = 400~1200范围内对管内层流传热性能的影响,结果表明其传热性能比传统纽带提高28%,且能有效降低流动阻力。Zhang等 [12] 研究了在Re = 300~1800范围内多根纽带对管内流动和传热的影响,结果表明相比与空管,使用三根和四根纽带能使努塞尔数Nu增加171%~182%,而摩擦系数f约为空管的4.06~7.02倍。另有学者对纽带式插入物进行结构改进并研究其对管内流动和传热的影响,如三角翼纽带 [13]、方形切角纽带 [14]、锯齿状纽带 [15]、带孔纽带 [16]、V型切角纽带 [17],等等。不过这些研究针对的均是低黏流体在高雷诺数下的湍流传热过程,对于高黏层流传热的研究还有待补充。

Figure 3. Flow mechanism in pipes with different number of twisted tapes and rotation directions [8]

图3. 不同数量纽带和旋转方向下管内流动机理示意图 [8]

还有学者研究了其他一些高效的管内插入物来提升管程层流混合与传热性能。Yu等 [18] 对Q型静态混合器(QSM)在Re = 20~100范围内的层流流动与传热特性进行数值模拟研究,发现流体在QSM中流动时产生分流、反向流动与径向流动,形成二次流,使得QSM能有效提高传热系数,但摩擦系数f也较大,为直管的3.5~6.4倍。Pérez-García等 [19] 分析了插入螺旋线圈的圆管内的流动与传热特性,结果表明在Re = 200~2000范围内,螺旋线圈能够有效强化管内传热。Tusar等 [20] 利用计算流体力学方法(Computational fluid dynamics, CFD)模拟研究发现插入螺带式插入物的圆管比普通空管的Nu和f分别增大1.34~2.6倍和3.5~8倍(Re = 200~2300)。Omara等 [21] 研究了可旋转的螺带式插入物对管内流动与传热特性的影响,实验雷诺数范围为Re = 580~1582,在Re = 580,螺带间距为0,转速为6 rpm时,Nu和f分别较空管增加112%和75%。

综上,目前对管程流动与传热特性的研究多针对低黏湍流过程,少数研究了在低雷诺数下的传热特性,但对高黏流体的层流传热强化研究则较少。与空管相比,异形传热管对管程层流传热过程的传热强化有一定作用,但效果有限;使用管内插入物则能起到明显的传热强化作用,但同时也显著增大了流动阻力。因而对于管程高黏流体的传热过程强化,研究开发高传热与低流动阻力并重的管程强化传热技术具有重要的意义。

3. 壳程强化传热

传统的高黏管壳式换热器多采用光滑管设计制造,壳程流动阻力与传热阻力较大,整体效能较低 [22]。壳程的传热强化主要包括两个方面:一是改变管子外形或在管外加翅片,即通过管子外形或表面性质的改造来强化传热;二是改变壳程折流板或管间支撑物的形式。

3.1. 管型及表面性质改造

翅片可以增大换热面积和增强扰动,提高传热系数,能有效强化低黏流体的传热过程。但翅片对高黏流体的扰动作用弱,且高黏流体易在翅片间滞留,使换热器易结垢难清洁。通过改变管子外形可以增加壳程流体的扰动并提高混合和传热性能。一些异形强化传热管对壳程流体有一定的强化传热作用,如扭曲管,其管与管间可相互支撑,可以使壳程流体不断地旋转,进而提高壳程混合和传热效率。另有一种螺旋式换热管 [23],其结构如图4(a)所示,这种螺旋结构能够增强壳程流体扰动,提高混合与换热效率,其还可形成如图4(b)所示的紧凑的换热管束或组成换热管组 [24] (图4(c)),作为高效换热器应用于壳程高黏流体的换热过程。另有专利 [25] [26] 报道了类似中国结型式的强化混合与传热装置(如图5所示),应用于壳程高黏聚合液的混合传热过程可获得更加均匀的速度分布和温度分布。相比于扭曲管等异形强化传热管,这种大幅度螺旋弯曲并形成高效紧凑的换热管束对壳程高黏流体的传热强化作用更为显著。

Figure 4. Spiral heat exchange tube

图4. 螺旋式换热管

Figure 5. Chinese knot type enhanced mixing and heat exchange device

图5. 中国结型式强化混合与换热装置

3.2. 折流板或管间支撑物

弓形折流板、螺旋折流板与整圆形折流板是常见的折流板型式,壳程流体在它们影响下的流动行为如图6所示 [27]。弓形折流板可以通过增强壳程流体的扰动和局部混合来改善换热,但也存在着壳程侧压降大、折流板与壳壁拐角处易形成滞留死区等缺点 [28]。通过对弓形数(单/双/三弓形等)、挡板参数(如板间距、缺口高度等)、开孔型式等的设计和优化可以不同程度地改善这些问题。例如,将多弓形折流板以一定角度倾斜配置可形成百叶窗形折流板(图7a),研究表明,相比于传统弓形折流板能有效减少流动死区,提高换热效率,降低压降 [29];或形成一种新型的扭转流换热器折流板(图7b),压降较弓形折流板降低42.5%~46.9%,综合性能提高7.2%~14.1% [30]。

Figure 6. Flow behavior of shell side fluid under the influence of: (a) segmental baffles, (b) spiral baffles, (c) longitudinal baffles [27]

图6. 不同折流板影响下壳程流体的流动行为:(a) 弓形折流板,(b) 螺旋折流板,(c) 纵流式折流板 [27]

螺旋折流板有效克服了弓形折流板存在的问题,流体能够连续流动,且在挡板附近不会出现流动死区,能够提高高黏流体的换热效率、减少壳程污垢和管束振动 [31]。朱冬生和蒋翔 [22] 通过实验研究比较了螺旋折流板换热器和弓形折流板换热器对高黏流体(0.03~0.05 Pa·s)的换热性能,发现前者的传热系数高于后者,且压降大幅减小。Zhang等 [32] 采用CFD方法研究并对比了连续螺旋折流板与非连续螺旋折流板的压降与传热性能,发现非连续螺旋折流板具有较高的传热性能与较小的压降。Du等 [33] 采用数值模拟方法研究了三分、四分与六分三种非连续螺旋折流板对换热器壳程流动与换热性能的影响,发现当流量增加时,场协同数Fc [1] (表明速度与温度梯度的协同程度,其值越大,表明传热强化作用越强)减小,单位体积传递热量减少;在相同流量下,Fc随着螺旋角增大而增加,传热性能得到提高,其中六分型式的螺旋折流板的传热性能最好,如图8所示。另外,Yang等 [34] 通过CFD研究发现非连续阶梯式螺旋折流板的强化传热作用优于弓形折流板和花格支撑板;Wang等 [35] 研究了非连续折叠式螺旋折流板对换热器壳程层流传热过程的强化作用,发现其综合性能优于弓形折流板,且Nu与f均随螺旋角的增大而增大。

Figure 7. (a) louver baffle, (b) torsion flow baffle

图7. (a) 百叶窗形折流板,(b) 扭转流折流板

Figure 8. Variation of Fc with Vs of trisection, quadrant and sextant helical baffles at different helix angles β [33]

图8. 三分、四分和六分螺旋折流板在不同螺旋角β下的场协同数Fc与壳程流量Vs的关系 [33]

整圆形折流板也被称为纵流式折流板,其特点是壳程流体通过板上的通孔纵向从管束间流过(图6c),在传热、减小压力损失和防垢等方面有较大的性能提高 [36] [37],但其相关研究基本都针对低黏物系,且值得注意的是,纵流式折流板也只有在大雷诺数的工况下才表现出较优的换热效果。另外折流杆在雷诺数较小或流速较低时综合性能也不明显 [38],对于壳程高黏流体的层流换热过程,折流杆和纵流式折流板则效果有限。

综上,壳程高黏流体的传热过程强化主要涉及管型的改进以及折流板或支撑物的结构设计与优化,以提升壳程混合与传热性能。与管程流体传热强化类似,提高壳程换热效率往往以提升壳程阻力为代价。之后的研究应在达到传热过程强化目的的同时,向着结构简单化与综合性能更优化的方向发展。

4. 复合强化传热技术

复合强化传热技术是将多种强化技术合理结合使用来增强传热的技术。Bharadwaj等 [39] 对在插入纽带的螺纹槽管中层流至湍流范围的压降和传热特性进行了实验研究,发现插入纽带能进一步增强由螺旋槽引起的传热增强效果。除此之外,还有纽带与缩放管结合 [40]、螺旋线圈与纽带插入物结合 [41]、波纹管结构与弹簧带插入物结合 [42]、波纹管结构与螺旋杆插入物结合 [43]、管槽结构与螺旋杆结合 [44] 等复合强化技术。另外,将异形管与大幅弯曲管型相结合也可进一步强化传热,如Rainieri等 [45] 实验研究了结合螺旋管与波纹管管型的复合式强化传热管在Re = 70~1200范围内的对流传热特性(Nu结果如图9所示),Chang等 [46] 采用CFD方法研究了结合扭曲管型与螺旋管型的复合式强化传热管内的传热特性。上述研究结果均表明,复合强化传热技术能获得比单一使用其中一种更好的传热性能,但同时也显著增加了流动阻力。

Figure 9. Variation of Nu with Re of spiral straight pipe (HSW) and spiral corrugated pipe (HCW) under different curvature ratio δ [45]

图9. 螺旋直管(HSW)和螺旋波纹管(HCW)在不同曲率比δ下的Nu与Re关系 [45]

5. 结语

与低黏流体的湍流机制强化传热不同,高黏流体的传热过程强化则需要通过设法减薄层流热边界层的厚度或破坏层流热边界层的发展,以及增强流体径向流动混合来实现。在提升高黏流体传热过程的同时,也会显著增大流动阻力,产生更多功耗,因而研究开发高传热与低流阻特性兼备的传热强化技术是研究与发展的趋势,同时考虑到经济性与安全性等因素,以获得更优的综合性能和更简单安全的结构是研究的重点。另外,使用复合强化传热技术获得的强化传热效果比单一技术更好,但会进一步增加流阻。如何将多种管程强化传热技术或将管程强化传热技术与壳程强化传热技术合理配合使用是一个重要的研究方向。

目前对管壳式换热器管程和壳程的传热过程强化研究大多针对的是低黏牛顿流体的湍流对流传热过程,仍需对高黏流体或超高黏流体(如聚合物熔体),尤其是具有复杂流变特性(剪切稀化特性、宾汉特性、粘弹性)的高黏流体的传热强化进行更多的深入研究。

基金项目

在此,谨向国家自然科学基金(22078284)的资助以及帮助过我的老师和同学表示诚挚的谢意,并向在百忙中抽出时间对本文进行评审并提出宝贵意见的各位专家老师表示衷心感谢!

文章引用

汪健清,施金玲,施龙生,王嘉骏,冯连芳. 管壳式换热器中高黏流体传热强化进展

Heat Transfer Enhancement Techniques for High-Viscosity Fluid in Shell-and-Tube Heat Exchanger[J]. 化学工程与技术, 2021, 11(04): 185-195. https://doi.org/10.12677/HJCET.2021.114026

参考文献

- 1. Guo, Z.Y., Li, D.Y. and Wang, B.X. (1998) A Novel Concept for Convective Heat Transfer. International Journal of Heat and Mass Transfer, 41, 2221-2225. https://doi.org/10.1016/S0017-9310(97)00272-X

- 2. Hong, Y.X., Du, J., Wang, S.F., et al. (2017) Heat Transfer and Flow Behaviors of a Wavy Corrugated Tube. Applied Thermal Engineering, 126, 151-166. https://doi.org/10.1016/j.applthermaleng.2017.07.135

- 3. 陈邦强, 李庆生. 横纹槽管管内流动与强化传热三维数值模拟[J]. 化学工程与装备, 2018(11): 14-18.

- 4. Du, J., Hong, Y.X., Huang, S.M., et al. (2018) Laminar Thermal and Fluid Flow Characteristics in Tubes with Sinusoidal Ribs. International Journal of Heat and Mass Transfer, 120, 635-651. https://doi.org/10.1016/j.ijheatmasstransfer.2017.12.047

- 5. Cheng, J.L., Qian, Z.Q. and Wang, Q. (2017) Analysis of Heat Transfer and Flow Resistance of Twisted Oval Tube in Low Reynolds Number Flow. International Journal of Heat and Mass Transfer, 109, 761-777. https://doi.org/10.1016/j.ijheatmasstransfer.2017.02.061

- 6. Murasiewicz, H. and Zakrzewska, B. (2019) Large Eddy Simulation of Turbulent Flow and Heat Transfer in a Kenics Static Mixer. Chemical and Process Engineering, 40, 87-99.

- 7. Zheng, N.B., Yan, F., Zhang, K., et al. (2020) A Review on Single-Phase Convective Heat Transfer Enhancement Based on Multi-Longitudinal Vortices in Heat Exchanger Tubes. Applied Thermal Engineering, 164, Article ID: 114475. https://doi.org/10.1016/j.applthermaleng.2019.114475

- 8. Vashistha, C., Patil, A.K. and Kumar, M. (2016) Experimental Investigation of Heat Transfer and Pressure Drop in a Circular Tube with Multiple Inserts. Applied Thermal Engineering, 96, 117-129. https://doi.org/10.1016/j.applthermaleng.2015.11.077

- 9. Kumar, B., Srivastava, G., Kumar, M., et al. (2018) A Review of Heat Transfer and Fluid Flow Mechanism in Heat Exchanger Tube with Inserts. Chemical Engineering and Processing: Process Intensification, 123, 126-137. https://doi.org/10.1016/j.cep.2017.11.007

- 10. Chokphoemphun, S., Pimsarn, M., Thainpong, C., et al. (2015) Thermal Performance of Tubular Heat Exchanger with Multiple Twisted-Tape inserts. Chinese Journal of Chemical En-gineering, 23, 755-762. https://doi.org/10.1016/j.cjche.2015.01.003

- 11. Li, P.X., Liu, Z.C., Liu, W., et al. (2015) Numerical Study on Heat Transfer Enhancement Characteristics of Tube Inserted with Centrally Hollow Narrow Twisted Tapes. International Journal of Heat and Mass Transfer, 88, 481-491. https://doi.org/10.1016/j.ijheatmasstransfer.2015.04.103

- 12. Zhang, X.Y., Liu, Z.C. and Liu, W. (2012) Numerical Studies on Heat Transfer and Flow Characteristics for Laminar Flow in a Tube with Multiple Regularly Spaced Twisted Tapes. International Journal of Thermal Sciences, 58, 157- 167. https://doi.org/10.1016/j.ijthermalsci.2012.02.025

- 13. Eiamsa-Ard, S., Wongcharee, K., Eiamsa-Ard, P., et al. (2010) Heat Transfer Enhancement in a Tube Using Delta-Winglet Twisted Tape Inserts. Applied Thermal Engineering, 30, 310-318. https://doi.org/10.1016/j.applthermaleng.2009.09.006

- 14. Murugesan, P., Mayilsamy, K. and Suresh, S. (2010) Turbulent Heat Transfer and Pressure Drop in Tube Fitted with Square- Cut Twisted Tape. Chinese Journal of Chemical Engineering, 18, 609-617. https://doi.org/10.1016/S1004-9541(10)60264-9

- 15. Eiamsa-Ard, S. and Promvonge, P. (2010) Thermal Characteristics in Round Tube Fitted with Serrated Twisted Tape. Applied Thermal Engineering, 30, 1673-1682. https://doi.org/10.1016/j.applthermaleng.2010.03.026

- 16. Bhuiya, M., Chowdhury, M., Saha, M., et al. (2013) Heat Transfer and Friction Factor Characteristics in Turbulent Flow through a Tube Fitted with Perforated Twisted Tape Inserts. International Communications in Heat and Mass Transfer, 46, 49-57. https://doi.org/10.1016/j.icheatmasstransfer.2013.05.012

- 17. Murugesan, P., Mayilsamy, K., Suresh, S., et al. (2011) Heat Transfer and Pressure Drop Characteristics in a Circular Tube Fitted with and without V-Cut Twisted Tape Insert. International Communications in Heat and Mass Transfer, 38, 329-334. https://doi.org/10.1016/j.icheatmasstransfer.2010.11.010

- 18. Yu, Y.F., Wang, H.Y., Song, M.Y., et al. (2016) The Effects of Element Direction and Intersection Angle of Adjacent Q-Type Inserts on the Laminar Flow and Heat Transfer. Applied Thermal Engineering, 94, 282-295. https://doi.org/10.1016/j.applthermaleng.2015.10.092

- 19. Pérez-García, J., García, A., Herrero, M.R., et al. (2018) Experimental Correlations on Critical Reynolds Numbers and Friction Factor in Tubes with Wire-Coil Inserts in Laminar, Transitional and Low Turbulent Flow Regimes. Experimental Thermal and Fluid Science, 91, 64-79. https://doi.org/10.1016/j.expthermflusci.2017.10.003

- 20. Tusar, M., Ahmed, K., Bhuiya, M., et al. (2019) CFD Study of Heat Transfer Enhancement and Fluid Flow Characteristics of Laminar Flow through Tube with Helical Screw Tape Insert. Energy Procedia, 160, 699-706. https://doi.org/10.1016/j.egypro.2019.02.190

- 21. Omara, M. (2016) Heat Transfer Performance through a Flat Tube Using Rotary Helical Screw-Tape Inserts. Experimental Heat Transfer, 29, 691-706. https://doi.org/10.1080/08916152.2015.1086842

- 22. 朱冬生, 蒋翔. 管壳式换热器壳程高黏度流体的传热强化[J]. 化工学报, 2005; 56(8): 1451-1455.

- 23. Pawar, S.S. and Sunnapwar, V.K. (2014) Experimental and CFD In-vestigation of Convective Heat Transfer in Helically Coiled Tube Heat Exchanger. Chemical Engineering Research and Design, 92, 2294-2312. https://doi.org/10.1016/j.cherd.2014.01.016

- 24. Karimov, R.M., Zaplatin, A.V. and Tashbulatov, R.R. (2019) Coiled Heat Exchanger with Small Radius Bent Tubes for Controlled Heat Treatment of High-Viscosity Waxy Oil. IOP Conference Series: Earth and Environmental Science, 272, Article ID: 022193. https://doi.org/10.1088/1755-1315/272/2/022193

- 25. 施龙生, 张鸿晨, 俞金芳, 等. 一种强化传热混合换热装置[P]. 中国专利, 106225520 B. 2017-04-19.

- 26. 杨蕴辉, 陈东辉, 施龙生, 等. 一种塔式聚合反应器[P]. 中国专利, 203484150 U. 2014-03-19.

- 27. Maakoul, A.E., Laknizi, A., Saadeddine, S., et al. (2016) Numerical Comparison of Shell-Side Performance for Shell and Tube Heat Exchangers with Trefoil-Hole, Helical and Segmental Baffles. Applied Thermal Engineering, 109, 175- 185. https://doi.org/10.1016/j.applthermaleng.2016.08.067

- 28. 夏红卫. 换热和混合设备的CFD模拟[D]: [硕士学位论文]. 青岛: 中国海洋大学, 2009.

- 29. Lei, Y.G., Li, Y.Z., Jing, S.L., et al. (2017) Design and Performance Analysis of the Novel Shell-and-Tube Heat Exchangers with Louver Baffles. Applied Thermal Engineering, 125, 870-879. https://doi.org/10.1016/j.applthermaleng.2017.07.081

- 30. 古新, 罗元坤, 熊晓朝, 等. 扭转流换热器结构参数对流场和温度场的影响[J]. 化工学报, 2018, 69(8): 3390-3397.

- 31. Movassag, S.Z., Taher, F.N., Razmi, K., et al. (2013) Tube Bundle Replacement for Segmental and Helical Shell and Tube Heat Exchangers: Performance Comparison and Fouling Investigation on the shell Side. Applied Thermal Engineering, 51, 1162-1169. https://doi.org/10.1016/j.applthermaleng.2012.10.025

- 32. Zhang, J.F., He, Y.L. and Tao, W.Q. (2009) 3D Nu-merical Simulation on Shell-and-Tube Heat Exchangers with Middle-Overlapped Helical Baffles and Continuous Baffles Part II: Simulation Results of Periodic Model and Comparison between Continuous and Non-Continuous Helical Baffles. International Journal of Heat and Mass Transfer, 52, 5381- 5389. https://doi.org/10.1016/j.ijheatmasstransfer.2009.07.007

- 33. Du, W.J., Wang, H.F. and Cheng, L. (2014) Effects of Shape and Quantity of Helical Baffle on the Shell-Side Heat Transfer and Flow Performance of Heat Exchangers. Chinese Journal of Chemical Engineering, 22, 243-251. https://doi.org/10.1016/S1004-9541(14)60041-0

- 34. Yang, S.F., Chen, Y.P., Wu, J.F., et al. (2020) Investigation on Shell Side Performance in Half-Cylindrical Desuperheating Zone of Ladder Type Helical Baffle Heat Exchangers. Ap-plied Thermal Engineering, 175, Article ID: 115334. https://doi.org/10.1016/j.applthermaleng.2020.115334

- 35. Wang, S.M., Xiao, J., Ye, S.P., et al. (2018) Numerical Investigation on Pre-Heating of Coal Water Slurry in Shell- and-Tube Heat Exchangers with Fold Helical Baffles. International Journal of Heat and Mass Transfer, 126, 1347- 1355. https://doi.org/10.1016/j.ijheatmasstransfer.2018.06.060

- 36. 魏国志, 李华峰, 柯双兵, 等. 三叶孔板强化换热性能及机理分析[J]. 化工进展, 2017, 36(2): 465-472.

- 37. Ma, L., Wang, K., Liu, M.S., et al. (2017) Numerical Study on Performances of Shell-Side in Trefoil-Hole and Quatrefoil-Hole Baffle Heat Exchangers. Applied Thermal Engineering, 123, 1444-1455. https://doi.org/10.1016/j.applthermaleng.2017.05.097

- 38. 王丽丽, 马贵阳. 纵流式换热器结构优化研究进展[J]. 当代化工, 2016, 45(8): 1937-1939.

- 39. Bharadwaj, P., Khondge, A.D. and Date, A.W. (2009) Heat Transfer and Pressure Drop in a Spirally Grooved Tube with Twisted Tape Insert. International Journal of Heat and Mass Transfer, 52, 1938-1944. https://doi.org/10.1016/j.ijheatmasstransfer.2008.08.038

- 40. Hong, Y.X., Deng, X.H. and Zhang, L.S. (2012) 3D Numerical Study on Compound Heat Transfer Enhancement of Converging-Diverging Tubes Equipped with Twin Twisted Tapes. Chinese Journal of Chemical Engineering, 20, 589- 601. https://doi.org/10.1016/S1004-9541(11)60223-1

- 41. Rout, P.K. and Saha, S.K. (2013) Laminar Flow Heat Transfer and Pressure Drop in a Circular Tube Having Wire-Coil and Helical Screw-Tape Inserts. Journal of Heat Transfer, 135, Article ID: 021901. https://doi.org/10.1115/1.4007415

- 42. Bhattaacharyya, S., Benim, A.C., Chattopadhyay, H., et al. (2019) Experimental Investigation of Heat Transfer Performance of Corrugated Tube with Spring Tape Inserts. Experimental Heat Transfer, 32, 411-425. https://doi.org/10.1080/08916152.2018.1531955

- 43. Emani, M.S., Ranjan, H., Bharti, A.K., et al. (2019) Laminar Flow Heat Transfer Enhancement in Square and Rectangular Channels Having: (1) A Wire-Coil, Axial and Spiral Corrugation Combined with Helical Screw-Tape with and without Oblique Teeth and a (2) Spiral Corrugation Combined with Twisted Tapes with Oblique Teeth. International Journal of Heat and Mass Transfer, 144, Article ID: 118707. https://doi.org/10.1016/j.ijheatmasstransfer.2019.118707

- 44. Shha, S. and Saha, S.K. (2013) Enhancement of Heat Transfer of Laminar Flow of Viscous Oil through a Circular Tube Having Integral Helical Rib Roughness and Fitted with Helical Screw-Tapes. Experimental Thermal and Fluid Science, 47, 81-89. https://doi.org/10.1016/j.expthermflusci.2013.01.003

- 45. Rainieri, S., Bozzoli, F. and Cattani, L. (2013) Compound Convective Heat Transfer Enhancement in Helically Coiled Wall Corrugated Tubes. International Journal of Heat and Mass Transfer, 59, 353-362. https://doi.org/10.1016/j.ijheatmasstransfer.2012.12.037

- 46. Chang, S.W., Wu, P.S., Cai, W.L., et al. (2020) Turbulent Flow and Heat Transfer of Helical Coils with Twisted Section. Applied Thermal Engineering, 180, Article ID: 115919. https://doi.org/10.1016/j.applthermaleng.2020.115919

NOTES

*通讯作者。