Advances in Material Chemistry

Vol.

08

No.

02

(

2020

), Article ID:

34993

,

8

pages

10.12677/AMC.2020.82003

High Performance Super-Hydrophobic Flower-Like CeO2 Micro/Nano-Structure Fabricated by Hydro-Thermal Method

Jianxin Lai, Huimin Lei, Le Ouyang, Jiaqi Xu, Zisheng Chao

College of Materials Science and Engineering, Changsha University of Science and Technology, Changsha Hunan

Received: Mar. 21st, 2020; accepted: Apr. 6th, 2020; published: Apr. 13th, 2020

ABSTRACT

A novel type of super-hydrophobic coating was successfully prepared on the aluminum sheet substrate via hydro-thermal synthesis methods combined with chemical modification. The addition of cerium oxide supplies the surface not only well distributed structures, but also unparalleled super-repellency, the static water contact angle could reach 160˚, and the rolling angle is not less than 5˚. The special wetting materials prepared by hydro-thermal synthesis can be continuously obtained by the process of regulating hydro-thermal method, and the materials show good super-hydrophobicity in a variety of harsh environments, which is of great reference significance for the large-scale production and application of hydrophobic materials.

Keywords:Micro/Nano-Structure, Hydro-Thermal Methods, Cerium Oxide, Super-Hydrophobicity, Stability

水热法制备高性能超疏水花状CeO2微纳米结构

赖健昕,雷慧敏,欧阳乐,徐嘉琪,晁自胜

长沙理工大学,材料科学与工程学院,湖南 长沙

收稿日期:2020年3月21日;录用日期:2020年4月6日;发布日期:2020年4月13日

摘 要

通过水热合成法构筑微纳结构,结合表面化学改性,成功地在铝片基底载体上制备了一种新型的超疏水涂层。稀土氧化铈的加入使得表面结构不仅均匀分布,材料表面也展现出超强排斥性,静态接触角可达到160˚,同时滚动角不超过5˚。水热合成法制备的特殊浸润性界面材料,可以通过调节水热法的工艺持续获得,且该材料在多种恶劣环境中均表现出较好的超疏水稳定性,对于疏水材料的大规模生产和应用都具备非常重大的借鉴意义。

关键词 :微纳结构,水热法,氧化铈,超疏水性,稳定性

Copyright © 2020 by author(s) and Hans Publishers Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY 4.0).

http://creativecommons.org/licenses/by/4.0/

1. 引言

自从自然界中的特殊浸润性生物表面 [1] [2] [3] [4] [5] 被发现以来,超疏水材料逐渐被越来越多研究人员关注,并且随着超疏水材料的理论发展、制造设备的不断升级,超疏水材料的制备方法 [6] [7] [8] [9] [10] 也在不断多样化,但无论采用何种方法制备疏水材料,构筑单级 [11] 或者分级 [12] 的复杂微纳结构以及低表面能化学修饰 [13] [14] [15] 总是包含在内。目前不同种类的超疏水材料不断被报道出来,其中不乏疏水性能非常优异的表面,但超疏水材料的批量生产和应用仍是一个难题。首先,超疏水材料的制备过程总是复杂和难以控制;其次由于部分有机物或其他成分的引入,最终的材料可能对环境或人有害;最后,绝大多数的超疏水材料的组成成分都不能忍受高温气氛的环境,化学腐蚀、紫外照射、振动和摩擦处理等因素也能使得疏水性能失效。总之,疏水性能的稳定性一直是超疏水材料研究中最具挑战性的部分。

目前已有不同种类的优良疏水材料的静态水接触角可达150˚以上,然而接触角高达160˚的超疏水表面却不是很普遍。无机金属氧化物相比有机材料更具热稳定性、机械稳定性和耐久性,在以往的研究中发现,稀土氧化物的引入可以一定程度地改善材料的浸润性能 [16] [17] [18]。例如氧化铈等镧系稀土氧化物,被证明具备一定本征疏水性 [19]。随着研究的进展,人们逐渐了解稀土氧化物的性能,越来越多的研究尝试将稀土氧化物应用到疏水材料的制备上。考虑到稀土氧化物的优点,本研究的主要任务是将稀土氧化物与超疏水材料结合起来,特别是用简单经济的方法制备性能稳定的超疏水表面。

近几年来,许多研究成果报道了不同的超疏水金属氧化物材料,如ZnO [20] 、TiO2 [21] 、SnO2 [22] 和V2O5 [23],在紫外、机械、高温和其他腐蚀性环境中暴露后表面呈现亲水性。而潘帅军等人 [24] 开发了一种高性能透明涂层,对有机溶剂、酸碱盐、聚合物溶液以及其他超低表面张力液体都具有超强的排斥力。Adam T. Paxson、Kripa K. Varanasi及其同事 [19] 证实,独特的电子结构有助于实现CeO2的固有疏水性。到目前为止,CeO2等稀土氧化物在不同环境下的疏水性、热稳定性和其他抗干扰性方面具有巨大的优越性 [16]。同时部分金属以及合金 [25] [26] [27] [28] 也被开发作为基底载体来制备CeO2超疏水涂层,Liu和他的团队 [26] 开发出了一种具备低表面能的超疏水Ce基金属玻璃表面,在玻璃表面构筑微纳米级结构和低表面能涂层化学改性即可获得相应的疏水性能。而Ishizakiet [27] 在镁合金表面构筑的纳米CeO2涂层具备优异的耐腐蚀性和持久性。另一种耐腐蚀的超疏水CeO2涂层通过一步电沉积工艺制备得到,该材料表面的接触角为162˚,滚动角小于4˚ [28]。

本文通过水热合成法构筑了一种结构规则、疏水性能优异的新型CeO2涂层材料,该表面可以对不同PH值和不同腐蚀性的溶液展现良好的排斥性,且水滴的静态接触角可达160˚,滚动角不大于5˚。更重要的是水热法构筑的CeO2结构在氟硅烷化学改性后,不仅获得超疏水性能,且非常稳定。简单经济的制备方法,在不同环境下的超疏水稳定性使其在户外应用中具有明显的优势。

2. 实验

2.1. 水热反应构筑CeO2微纳结构

基底材料选用4 × 4 cm的铝片,利用1500目的细砂纸均匀打磨两侧,用0.1 mol/L的稀HNO3溶液浸泡5 min,对表面进行亲水化处理。以Ce(NO3)3·5H2O作为铈源,尿素充当水热反应的沉淀剂和导向剂,配置成一定浓度的水热生长液,100℃水热反应24 h后随炉冷却至室温。水热反应完成后进行充分干燥,置于马弗炉中以450℃保温3 h后的材料就完成微纳结构的构筑,实验过程中所用仪器和药品如表1所示。

Table 1. Reagent and instrument

表1. 试剂与仪器

2.2. 表面化学修饰

表面化学改性所用到的低表面能有机物为1H,1H,2H,2H-全氟十二烷基–三乙氧基硅烷,以正己烷作为有机溶剂,配置成质量浓度为0.1 wt%的有机溶液,磁力搅拌1h保证混合均匀。室温下将材料完全浸泡在有机溶液中,24 h后取出100℃干燥12 h后即可完成表面的化学修饰过程。

2.3. 稳定性检测

为了检测疏水材料表面在不同严苛环境下疏水性能的稳定性,对疏水材料的稳定性做了如下条件的检测:酸碱盐溶液、抗腐蚀环境、高热环境、紫外光照射等环境,观察这些因素对材料表面老化的影响。

3. 结果和讨论

3.1. 超疏水表面

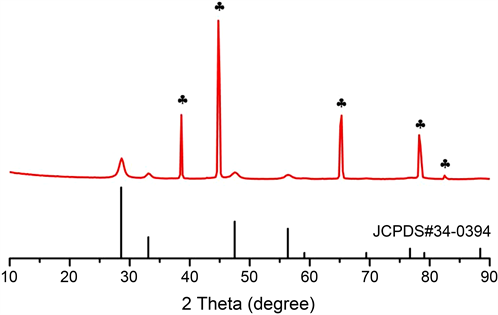

通过水热合成法在铝片表面顺利得到的白色涂层,轻轻漂洗干燥后放入马弗炉中进行高温烧结,铝片上最终得到一层淡黄色的涂层材料,为了有效了解其化学成分,通过X射线粉末衍射对表面涂层材料进行晶体组成的判断,结果如图1所示。

由XRD结果可以得出,材料的XRD图谱中含有较明显的CeO2特征峰,主峰位置分别为28.6˚,33.1˚,47.4˚,56.4˚,而其余在位置38.5˚,45.2˚,65.3˚,78.5˚的峰则为铝的特征峰,且无其他明显杂质的存在,故可以判断水热生长和后期的高温烧结后,铝片上面的涂层主要成分是CeO2。

Figure 1. XRD spectrum of super-hydrophobic materials

图1. 超疏水材料的XRD图谱

对CeO2超疏水表面做了形貌的观察,可以从SEM图片中可以看出,通过水热合成法顺利在铝片表面制备了花状的CeO2微纳结构,且不同类型的结构呈现均匀分布,如图2所示。

Figure 2. SEM image of rose shaped CeO2 structures. a-d represent the structures from low to high magnification in SEM image

图2. 玫瑰花状CeO2微纳结构的SEM图片,a-d分别为玫瑰花状结构从低倍到高倍的电镜图片

由图2中的花状CeO2结构可以得出,它们具有明显的分级机制,可以对超疏水表面的滚动角减小有一定的推动作用,且不同结构在超疏水化后均可以得到较大的接触角。

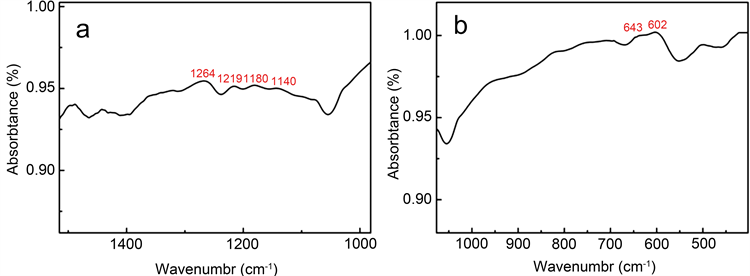

为了验证化学修饰的效果和解释CeO2微纳结构在化学修饰后获得超疏水性能的原因,对超疏水化后的材料表面进行红外能谱表征,观察表面官能团的附着情况,为PFAS嫁接后CeO2涂层的FTIR光谱,波长范围在550~650 cm−1和1150~1250 cm−1的峰证实了-CF3-和-CF2-官能团 [29] [30] [31] [32] 的存在。由此推测PFAS分子通过缩聚反应附着在微纳结构的表面,降低了材料表面的表面自由能,使得表面获得相应的超疏水性能,红外光谱分析结果如图3所示。

Figure 3. Infrared spectra of super-hydrophobic CeO2 coating. The peaks at ~1150 - 1250 cm−1 (a) and ~550 - 650 cm−1 (b) confirmed -CF3- and -CF2- functional groups, which reduced the free energy of the surfaces of ceramic balls

图3. 超疏水CeO2涂层的红外光谱,图a为红外光谱在1150~1250 cm−1区间的-CF2-特征峰,图b为红外光谱在550~650 cm−1区间的-CF3-特征峰

3.2. 超排斥性

众所周知,材料表面的静态接触角和滚动角是衡量其疏水性能的重要指标之一,对此我们也检测了不同CeO2微纳结构在疏水化后的浸润性能变化,经过检测发现,不同类型的超疏水CeO2涂层表面接触角最高可达160˚,滚动角不超过5˚,检测过程中水滴与材料表面很难发生有效的粘连,且水滴在该材料表面属于过渡模型的浸润状态,具体过程如图4所示。

Figure 4. Super-hydrophobicity of the rose shaped CeO2 structures. (a) represented water adhesive tests process on the coating surfaces; (b) injected water droplet rolling quickly when the surface tilted slightly at 2˚; (c) static water contact angle of CeO2 coating can attach 160˚; (d) the hydrophobic state happened on the surface

图4. 玫瑰花状CeO2微纳结构的超疏水性能,(a) 材料表面的粘附性能;(b) 水滴可以在稍微倾斜的材料表面滚落;(c) 水热合成法制备的材料表面疏水性能;(d) 材料表面的疏水状态属于Wenzel-Cassie过渡状态

3.3. 疏水稳定性

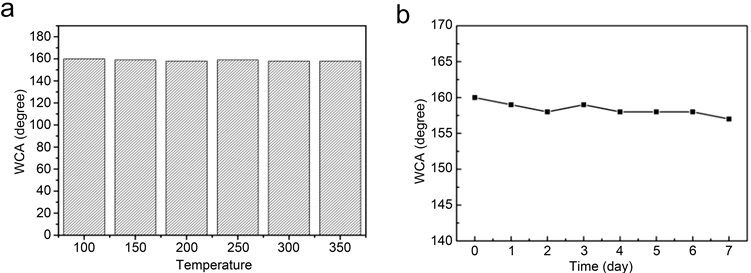

众所周知超疏水材料的制备和应用过程中,材料的疏水稳定性一直是最关键的部分之一。实验中我们模拟了紫外光照和高温环境用于观察材料的耐候性能和疏水性能的稳定性,过程中采用了10 v的紫外光灯,保证50 cm的照射距离,以及100℃~350℃的高温加热环境,结果如图5所示。

Figure 5. Super-stability of the rose shaped CeO2 structures. (a) Hydrophobicity of materials under thermal treatment; (b) Hydrophobicity of materials under UV irradiation treatment

图5. 超疏水CeO2材料的稳定性,(a) 材料表面的疏水性能在高温环境下的变化;(b) 材料在紫外光照射下疏水性能的变化

如图5所示,制备的超疏水CeO2涂层可以在高温和紫外光照环境下稳定维持较好的疏水性能,性能可以在350℃的高温下保温2 h不发生明显变化,而在紫外照射7天后材料表面的疏水接触角仍可以保持在158˚以上。

4. 结论

近年来,疏水材料作为一门基础科学,无论是理论认识还是实际应用都在逐渐走向成熟,不同类型的方法被用于超疏水材料的制备和研究,却始终没有办法回避特殊浸润材料的制备条件苛刻、批量化生产、功能多样化、性能不稳定等诸多应用问题。当前构建一个低成本、易制备、耐候好性的浸润性材料尤为关键,稀土氧化物的引入不仅可以增加微纳形貌的选择,还可以改善材料自身的耐候性能,在材料完成超疏水化后将疏水稳定性进一步优化,为材料的实际应用提供重要的借鉴。

水热合成法作为一种有效的制备方法,无需复杂的设备和加工方法,建立合理的工艺标准,不仅可以保证材料的微纳结构均匀分布,简单的化学修饰可以让材料获得疏水性能并保证在一般的外界环境不受破坏。以CeO2为代表的镧系无机金属氧化物具有无机氧化物没有的热稳定性、机械稳定性和耐候性,作为环境友好型材料的代表更是符合未来发展的趋势。

文章引用

赖健昕,雷慧敏,欧阳乐,徐嘉琪,晁自胜. 水热法制备高性能超疏水花状CeO2微纳米结构

High Performance Super-Hydrophobic Flower-Like CeO2 Micro/Nano-Structure Fabricated by Hydro-Thermal Method[J]. 材料化学前沿, 2020, 08(02): 15-22. https://doi.org/10.12677/AMC.2020.82003

参考文献

- 1. Barthlott, W. and Neinhuis, C. (1997) Purity of the Sacred Lotus, or Escape from Contamination in Biological Surfaces. Planta, 202, 1-8.

https://doi.org/10.1007/s004250050096 - 2. %Parker, A.R. and Lawrence, C.R. (2001). Water Capture by a Desert Beetle. Nature, 414, 33-34.

https://doi.org/10.1038/35102108 - 3. %Feng, X.Q., Gao, X., Wu, Z., Jiang, L. and Zheng, Q.S. (2007) Su-perior Water Repellency of Water Strider Legs with Hierarchical Structures? Experiments and Analysis. Langmuir, 23, 4892-4896.

https://doi.org/10.1021/la063039b - 4. %Zheng, Y., Gao, X. and Jiang, L. (2007) Directional Adhesion of Superhydrophobic Butterfly Wings. Soft Matter, 3, 178-182.

https://doi.org/10.1039/B612667G - 5. %Dai, X., Sun, N., Nielsen, S.O., Stogin, B.B. and Wong, T.S. (2018) Hydrophilic Directional Slippery Rough Surfaces for Water Harvesting. Science Advances, 4, eaaq0919.

https://doi.org/10.1126/sciadv.aaq0919 - 6. %Wang, S., Liu, K., Yao, X. and Jiang, L. (2015) Bioinspired Surfaces with Superwettability: New Insight on Theory, Design, and Applications. Chemical Reviews, 115, 8230-8293.

https://doi.org/10.1021/cr400083y - 7. %Liu, K., Yao, X. and Jiang, L. (2010) Recent Develop-ments in Bio-Inspired Special Wettability. Chemical Society Reviews, 39, 3240-3255.

https://doi.org/10.1039/b917112f - 8. %Liu, M., Wang, S. and Jiang, L. (2017) Nature-Inspired Superwetta-bility Systems. Nature Reviews Materials, 2, Article No. 17036.

https://doi.org/10.1038/natrevmats.2017.36 - 9. %Yin, K., Du, H., Dong, X., Wang, C., Duan, J.-A. and He, J. (2017) A Simple Way to Achieve Bioinspired Hybrid Wettability Surface with Micro/Nanopatterns for Efficient Fog Collection. Nanoscale, 9, 14620-14626.

https://doi.org/10.1039/C7NR05683D - 10. %Fadeeva, E., Truong, V.K., Stiesch, M., Chichkov, B.N., Craw-ford, R.J., Wang, J. and Ivanova, E.P. (2011) Bacterial Retention on Superhydrophobic Titanium Surfaces Fabricated by Femtosecond Laser Ablation. Langmuir, 27, 3012-3019.

https://doi.org/10.1021/la104607g - 11. %Tuteja, A., Choi, W., Ma, M., Mabry, J.M., Mazzella, S.A., Rutledge, G.C., McKinley, G.H. and Cohen, R.E. (2007) Designing Superoleophobic Surfaces. Science, 318, 1618-1622.

https://doi.org/10.1126/science.1148326 - 12. %Liu, T.L. and Kim, C.-J.C. (2014) Turning a Surface Su-perrepellent Even to Completely Wetting Liquids. Science, 346, 1096-1100.

https://doi.org/10.1126/science.1254787 - 13. %Feng, L., Li, S.H., Li, Y., Li, H.J. and Zhu, D.B. (2003) Su-per-Hydrophobic Surfaces: From Natural to Artificial. ChemInform, 14, 1857-1860.

https://doi.org/10.1002/chin.200307200 - 14. %Deng, X., Mammen, L., Butt, H.J. and Vollmer, D. (2012) Candle Soot as a Template for a Transparent Robust Superamphiphobic Coating. Science, 335, 67-70.

https://doi.org/10.1126/science.1207115 - 15. %Wong, T.S., Kang, S.H., Tang, S.K.Y., Smythe, E.J., Hatton, B.D., Grinthal, A., et al. (2011) Bioinspired Self-Repairing Slippery Surfaces with Pressure-Stable Omniphobicity. Nature, 477, 443-447.

https://doi.org/10.1038/nature10447 - 16. %Li, X.P., Sun, Y.L., Xu, Y.Y. and Chao, Z.S. (2018) UV-Resistant and Thermally Stable Superhydrophobic CeO2 Nanotubes with High Water Adhesion. Small, 14, e1801040.

https://doi.org/10.1002/smll.201801040 - 17. %Azimi, G., Kwon, H.M. and Varanasi, K.K. (2014) Superhydrophobic Surfaces by Laser Ablation of Rare-Earth Oxide Ceramics. MRS Communications, 4, 1-5.

https://doi.org/10.1557/mrc.2014.20 - 18. %Nakayama, K., Hiraga, T., Zhu, C., et al. (2017) Facile Preparation of Self-Healing Superhydrophobic CeO2 Surface by Electrochemical Processes. Applied Surface Science, 423, 68-976.

https://doi.org/10.1016/j.apsusc.2017.07.012 - 19. %Li, J., Jing, Z., Yang, Y., Wang, Q. and Lei, Z. (2014) From Cassie State to Gecko State: A Facile Hydrothermal Process for the Fabrication of Superhydrophobic Surfaces with Controlled Sliding Angles on Zinc Substrates. Surface and Coatings Technology, 258, 973-978.

https://doi.org/10.1016/j.surfcoat.2014.07.047 - 20. %Feng, X., Feng, L., Jin, M., Zhai, J., Jiang, L. and Zhu, D. (2004) Reversible Super-Hydrophobicity to Super-Hydrophilicity Transition of Aligned ZnO Nanorod Films. Journal of the American Chemical Society, 126, 62-63.

https://doi.org/10.1021/ja038636o - 21. %Feng, X., Zhai, J. and Jiang, L. (2005) The Fabrication and Switch-able Superhydrophobicity of TiO2 Nanorod Films. Angewandte Chemie, 117, 5245-5248.

https://doi.org/10.1002/ange.200501337 - 22. %Zhu, W., Feng, X., Feng, L. and Jiang, L. (2006) UV-Manipulated Wettability between Superhydrophobicity and Superhydrophilicity on a Transparent and Conduc-tive SnO2 Nanorod Film. Chemical Communications (Camb), 26, 2753-2755.

https://doi.org/10.1039/b603634a - 23. %Lim, H.S., Kwak, D., Lee, D.Y., Lee, S.G. and Cho, K. (2007) Uv-Driven Reversible Switching of a Roselike Vanadium Oxide Film between Superhydrophobicity and Superhy-drophilicity. Journal of the American Chemical Society, 129, 4128-4129.

https://doi.org/10.1021/ja0692579 - 24. %Pan, S.J., Guo, R., Björnmalm, M., Richardson, J.J., Li, L., Peng, C., Bertleff-Zieschang, N., Xu, W.J., Jiang, J.H. and Caruso, F. (2018) Coatings Super-Repellent to Ultralow Surface Tension Liquids. Nature Materials, 17, 1040-1047.

https://doi.org/10.1038/s41563-018-0178-2 - 25. %Yuan, Z., Bin, J., Wang, X., Peng, C., Wang, M., Xing, S., Xiao, J., Zeng, J., Xiao, X., Fu, X. and Chen, H. (2014) Fabrication of Superhydrophobic Surface with Hierarchical Multi-Scale Structure on Copper Foil. Surface and Coatings Technology, 254, 151-156.

https://doi.org/10.1016/j.surfcoat.2014.06.004 - 26. %Liu, K., Li, Z., Wang, W. and Jiang, L. (2011) Facile Creation of Bio-Inspired Superhydrophobic Ce-Based Metallic Glass Surfaces. Applied Physics Letters, 99, Article ID: 261905.

https://doi.org/10.1063/1.3672036 - 27. %Ishizaki, T., Masuda, Y. and Sakamoto, M. (2011) Corrosion Resistance and Durability of Superhydrophobic Surface Formed on Magnesium Alloy Coated with Nanostructured Cerium Oxide Film and Fluoroalkylsilane Molecules in Corrosive NaCl Aqueous Solution. Langmuir, 27, 4780-4788.

https://doi.org/10.1021/la2002783 - 28. %Liu, C., Su, F., Liang, J. and Huang, P. (2014) Facile Fabrication of Superhydrophobic Cerium Coating with Micro-Nano Flower-Like Structure and Excellent Corrosion Resistance. Surface and Coatings Technology, 258, 580-586.

https://doi.org/10.1016/j.surfcoat.2014.08.032 - 29. %Peng, C., Chen, Z. and Tiwari, M.K. (2018) All-Organic Superhydrophobic Coatings with Mechanochemical Robustness and Liquid Impalement Resistance. Nature Mate-rials, 17, 355-360.

https://doi.org/10.1038/s41563-018-0044-2 - 30. %Xu, W., Song, J., Sun, J., Lu, Y. and Yu, Z. (2011) Rapid Fabrication of Large-Area, Corrosion-Resistant Superhydrophobic Mg Alloy Surfaces. ACS Applied Materials & Interfaces, 3, 4404-4414.

https://doi.org/10.1021/am2010527 - 31. %Song, J., Xu, W., Liu, X., Lu, Y., Wei, Z. and Wu, L. (2012) Ultrafast Fabrication of Rough Structures Required by Superhydrophobic Surfaces on Al Substrates Using an Immersion Method. Chemical Engineering Journal, 211-212, 143-152.

https://doi.org/10.1016/j.cej.2012.09.094 - 32. %Guo, X., Li, X., Wei, Z., Li, X. and Niu, L. (2016) Rapid Fabrication and Characterization of Superhydrophobic Tri-Dimensional Ni/Al Coatings. Applied Surface Science, 387, 8-15.

https://doi.org/10.1016/j.apsusc.2016.06.068