Journal of Advances in Physical Chemistry

Vol.

12

No.

02

(

2023

), Article ID:

65690

,

13

pages

10.12677/JAPC.2023.122012

柔性压力传感器及其应用研究进展

黄鹏举

上海理工大学机械工程学院,上海

收稿日期:2023年4月4日;录用日期:2023年5月15日;发布日期:2023年5月23日

摘要

随着科学技术的发展,可穿戴电子设备因其在健康监测、人机界面、软机器人等领域的巨大应用潜力而备受关注。相比于传统电子器件,柔性电子器件特有的柔韧性和延展性使其能够适应更多复杂的工作环境。柔性可穿戴传感系统是可穿戴电子设备的重要组成部分,其中,柔性压力传感器作为医疗电子设备的核心器件,可实现对外界信息的获取和转换,是整个系统与外界关联的窗口,因此确保传感器所获取信息的准确性至关重要。本篇综述介绍了近年来柔性压力传感器研究的进展,主要包括柔性压力传感器的传感原理、材料选择、性能参数及其在健康监测方面的应用,最后对柔性压力传感器的发展进行了展望。

关键词

柔性压力传感器,可穿戴传感器,健康监测

Research Progress on Flexible Pressure Sensors and Their Applications

Pengju Huang

School of Mechanical Engineering, University of Shanghai for Science and Technology, Shanghai

Received: Apr. 4th, 2023; accepted: May 15th, 2023; published: May 23rd, 2023

ABSTRACT

With the development of science and technology, wearable electronic devices have attracted much attention because of their great potential for applications in health monitoring, human-machine interface, soft robotics, and other fields. Compared with traditional electronics, the unique flexibility and ductility of flexible electronics enable them to adapt to more complex working environments. Flexible wearable sensing system is an important part of wearable electronic devices, among which, flexible pressure sensor, as the core device of medical electronic devices, can realize the acquisition and conversion of external information, and is the window of the whole system to the external world, so it is crucial to ensure the accuracy of the information acquired by the sensor. This review introduces the progress of flexible pressure sensor research in recent years, mainly including the sensing principle, material selection, performance parameters of flexible pressure sensors and their applications in health monitoring, and finally provides an outlook on the development of flexible pressure sensors.

Keywords:Flexible Pressure Sensor, Wearable Sensor, Health Monitoring

Copyright © 2023 by author(s) and Hans Publishers Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY 4.0).

http://creativecommons.org/licenses/by/4.0/

1. 引言

近年来,随着人们生活水平的提高和科学技术的发展,当代年轻人的老年病、慢性病和各种亚健康状态问题日益突出。同时,面对医疗资源紧缺、医疗费用不断上涨的现状,采用健康监测的方式不仅可以大大缓解这些问题,还可以提高医生问诊的便利性和病人的生活质量。因此,迫切需要研发更好、更快、更具可移动性的医疗电子设备,以监测人体健康各项指标,包括心率、呼吸、脉搏、血压、血氧和运动等信号。柔性压力传感器作为医疗电子设备的核心器件,可实现对外界信息的获取和转换,是整个系统与外界关联的窗口,因此确保传感器所获取信息的准确性至关重要。柔性压力传感器以其超薄、低模量、重量轻、高灵敏度和可伸缩性等独特的特性而受到人们的广泛关注,其在健康监测 [1] [2] [3] 、人机交互 [4] [5] [6] [7] 、可穿戴设备 [8] [9] [10] 和智能机器人 [11] [12] [13] 等领域具有广阔的发展前景。其中,柔性传感器在面向人体运动及生命体征信号监测方面的应用研究备受关注,它能对人体活动产生的电信号进行测量和量化。

本文根据压力传感器的传感机制对其进行分类,包括压阻式,电容式和压电式,分别对它们的工作机制,材料选择以及在健康监测方面的应用进行了描述。

2. 柔性压力传感器

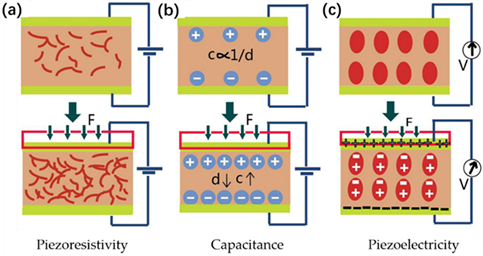

Figure 1. Schematic diagram of the three principles of sensors (a) Piezoresistive; (b) Capacitive; (c) Piezoelectric

图1. 传感器三种原理示意图(a) 压阻型;(b) 电容型;(c) 压电型

在柔性传感器中,压力传感器是柔性和可穿戴电子设备中最重要的部件之一,它可以将来自外界的机械刺激或变形转换成电信号。根据这些机械变形转化为电信号的机制不同,传感器主要可分为压阻式(piezoresistive)、电容式(capacitive)、压电式(piezoelectric)传感器。如图1为三种不同种类柔性压力传感器的工作原理图。

2.1. 压阻型传感器

压阻式压力传感器的工作原理是压阻效应。压阻效应是指当传感器收到外界的压力或拉力时,内部的敏感材料状态或者与电极的接触状态发生改变,从而导致电阻和电流产生变化。根据电阻的定义

(1.1)

其中, 是电阻率,L是长度,S是横截面积。压阻式压力传感器的工作机理较为简单,能量消耗小,因此受到了研究者们的广泛关注。

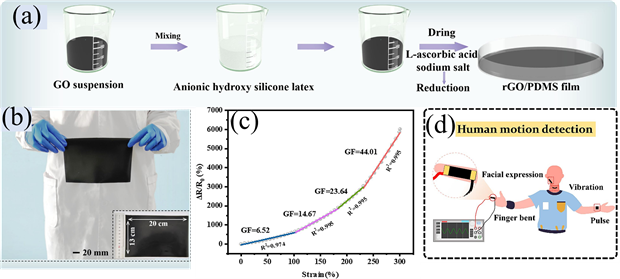

Wang课题组等人首次采用胶乳组装技术,研制了一种基于还原氧化石墨烯/聚二甲基硅氧烷(RGO/PDMS)导电弹性复合材料的三维导电网络柔性应变传感器 [14] ,如图2所示。利用胶乳颗粒的排除体积,使RGO选择性地位于它们之间的间隙中,从而形成了一个具有超低含量(0.44 vol%)的三维导电网络,从而使RGO/PDMS复合材料具有机械稳定性和柔性。值得注意的是,每一个PDMS胶乳颗粒都类似于一个“弹性气球”,在外界刺激下有助于导电网络的破坏和重建,从而赋予传感器极好的灵敏度。实验结果表明,所设计的应变传感器具有高灵敏度(GF = 44.01)和可循环性(2500次)以及高伸缩性(0~300%)的优点,在大规模人体运动检测中具有很强的应用前景。同时,该应变传感器能有效地检测人体细微的运动,如手指弯曲、面部表情变化、声带振动、脉搏和说话等。

Figure 2. RGO/PDMS pressure sensor [14] (a) Preparation work of RGO/PDMS film; (b) Optical diagram of RGO/PDMS film prepared by process scaling (20 cm × 13 cm); (c) Variation of relative resistance of RGO/PDMS strain sensor with strain and GF in different linear regions; (d) Schematic diagram of human motion detection

图2. RGO/PDMS压力传感器 [14] (a) RGO/PDMS薄膜的制备工;(b) 工艺放大制备的RGO/PDMS薄膜的光学图(20 cm × 13 cm);(c) 不同线性区域RGO/PDMS应变传感器相对电阻随应变和GF的变化;(d) 人体运动检测示意图

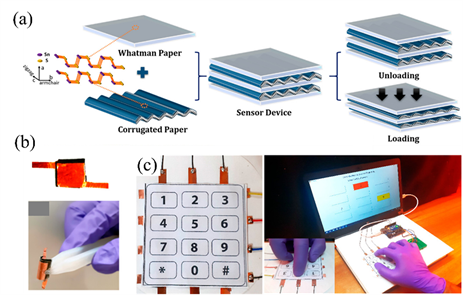

Neha Sakhuja课题组等人设计了一种新型多层纸结构的压力传感器 [5] ,如图3所示,该传感器结构是通过涂有2D单硫化锡(SnS)传感材料的平面和瓦楞纸片交替堆叠而成的。这种纸张压力传感器具有高达14.8 kPa−1的高灵敏度和0~120 kPa的宽工作范围,以及出色的循环稳定性(20000个循环),此外,该纸传感器还可以实时监测不同的人类活动(咬合、握拳、弯曲手指和轻击),并被开发出可折叠和可生物降解的人机交互键盘。

Figure 3. Multi-layer paper-based pressure sensor [5] (a) Flow chart of sensor preparation from alternating stacks of plain paper and corrugated paper; (b) Optical photograph of flexible foldable pressure sensor; (c) Demonstration of paper-based foldable keyboard

图3. 多层纸基压力传感器 [5] (a) 由平纹纸和瓦楞纸交替堆叠而成的传感器制备流程图;(b) 柔性可折叠压力传感器的光学照片;(c) 演示基于纸的可折叠键盘

2.2. 电容型传感器

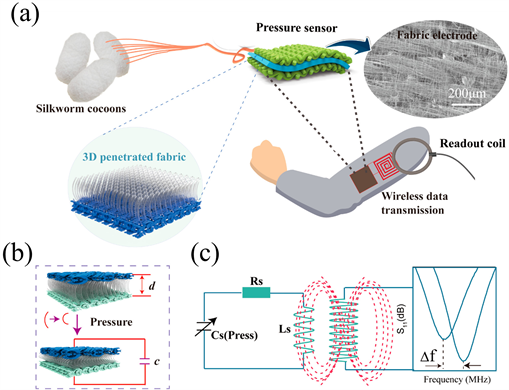

Figure 4. (a) Schematic diagram of LC monitoring pressure sensor [15] ; (b) Schematic diagram of 3D penetration of the fabric as a dielectric layer when the capacitive sensor changes under pressure; (c) Schematic diagram of the capacitive sensor wireless monitoring system.

图4. (a) LC监测压力传感器原理图 [15] ;(b) 电容传感器在压力下变化时作为介电层的3D穿透织物示意图;(c)电容传感器无线监测系统示意图。

电容式传感器一般由电极和介电层组成。电容式传感器的工作原理是:在外力作用下,传感器两块极板之间的距离发生变化,或者是表面积变化,从而导致电容量改变。电容(C)的计算公式为:

(1.2)

其中, 为真空介电常数, 为介电材料的相对介电常数,A为两导电层的有效面积,d为电容极板间距。拉伸后,电容式传感器的电容面积发生变化,介质层厚度减小,导致柔性传感器的电容值增大。

Wu课题组等人成功地制作了一种具有无线无电池监测系统的全织物压力传感器 [15] ,如图4所示,该传感器将三维穿透织物夹在两个高导电织物电极之间作为介电层。由于间隔织物具有良好的弹性和恢复性,电容压力传感器具有高灵敏度0.283 kPa−1,响应时间快,循环稳定性好(≥20000)。此外,还成功地设计和制作了共面织物传感器阵列,用于空间映射解析的压力信息。更重要的是,透气织物可以贴在皮肤上,通过谐振移频灵敏度为6.8 MHz/kPa的光纤电感线圈进行无线实时压力检测。

2.3. 压电性传感器

压电式传感器的传感机制是施加在压电介电材料上的力通过变形产生机械应力时,介电材料中偶极矩的变化产生电势。压电材料在外界刺激的影响下产生电荷,从而产生电响应的透过率和对外界变化的检测。由于施加的机械应力,在压电材料的内部偶极子的体积中发生电极化,在压电材料的两个相对表面之间出现电位差。由于所施加的外部机械应力是变化的,电信号的差异也是变化的。压电开路电压表达式为:

(1.3)

式中,A为面积,d33为压电系数, 为介电常数,h为厚度, 为机械应力。由于压电材料的特殊特性,压电传感器可以有效地响应高频信号,是一种非常适合于自供电的器件。

Figure 5. (a) Schematic diagram of IOF sensor structure [16] ; (b) Preparation process of BP film; (c) Preparation process of MXene material; (d) Temperature sensitivity; (e) Pressure sensitivity; (f) Piezoelectric sensitivity

图5. (a) IOF传感器结构示意图 [16] ;(b) BP薄膜的制备工艺;(c) MXene材料的制备工艺;(d) 温度灵敏度;(e) 压力敏感性;(f) 压电灵敏度

Yu课题组利用压电薄膜的热压方法和压电层的注入可变形模具的方法成功地设计和制备了压阻型压电/热变色传感器 [16] ,如图5所示。该传感器集成了热变色、压阻和压电三种功能,具有广泛的热变色范围、高灵敏度的压电响应和广泛的压阻检测范围。温度显示功能可在30℃至150℃白色范围内显示,在40 N的压力下最大温度-电压变化灵敏度约0.7 V∙C−1。压阻式传感器的最大探测范围为300 kPa,最大灵敏度为0.835 kPa−1。压电输出电压约为80 V,压电灵敏度为1.398 V∙kPa−1。此外,该传感器还具有实时监测吞咽咽喉、拍手和弯曲手指等人类行为的功能。因此,所研究的多功能传感器在人机交互方面具有重要的实际应用潜力。

在上述三种不同结构的传感器中,电容式压力传感器具有结构简单、准确度高、信号漂移少等优点,但其稳定性较差,在长期工作中易引起灵敏度下降。压电式压力传感器因其自身驱动的优势,可在某些苛刻条件下对信号进行长期监测,节约了大量的人力和物力,但需要特殊的材料、复杂的结构和繁琐的加工过程,且不能实现对动态力的测量。相对于其它类型的传感器,压阻式压力传感器具有制备工艺简单,能耗低,性能稳定,抗干扰能力强,灵敏度高,应用范围广,易于成阵,可实现系统集成和智能化。由于这些优点,压阻式柔性压力传感器成为近年来的研究热点,并广泛应用于可穿戴领域。

3. 压力传感器的组成

为了制备出性能优异的柔性压力传感器,材料选择和结构设计非常关键。一般地,柔性压力传感器主要由柔性基板、传感材料和电极组成。此外,传感器的性能由柔性基板、传感材料以及电极的功能和相互作用决定的,所以我们必须考虑每一部分的选择。

3.1. 柔性基板

柔性基板是压力传感器的主要部件,具有柔韧性和延展性,可以轻松地与人体的任何部位结合在一起。传统的刚性衬底材料,如二氧化硅(SiO2)、硅(Si)和石英,只有当这些材料的厚度减小到几十纳米时其才显示出机械柔性,同时机械强度也减弱。因此,需要具有优异的机械柔性和强度的可拉伸基底可以在复杂变形下保持系统的稳定性。许多聚合物材料,如聚二甲基硅氧烷(PDMS) [17] [18] [19] ,聚酯(聚对苯二甲酸乙二醇酯(PET) [20] [21] 和聚萘二甲酸乙二醇酯(PEN) [22] ),聚氨酯(PU) [23] [24] ,聚醚砜(PES),聚醚醚酮(PEEK)和聚酰亚胺(PI) [25] [26] ,由于其固有的机械柔性而被广泛选择作为压力传感器的柔性衬底。此外,大多数弹性聚合物无毒且易加工,减少了我们在制备传感器过程中的风险。其中,PDMS以其优异的拉伸性能、高的热稳定性和化学稳定性、低的成本等优势,成为一种极具应用前景的硅橡胶材料。由于其轻薄、透气和优良的生物相容性,可以直接附在人体皮肤上而不会引起过敏反应,也可以作为柔性组织工程材料植入体内。此外,由于PDMS在固化之前是液态的,因此可以简单加工成各种形状,例如半球形 [27] [28] [29] 、金字塔形 [30] [31] 、微柱形等微结构。此外,由于内部存在丰富的氢键,聚乙烯醇(PVA)具有自我修复特性 [32] ,这使得具有PVA基材的柔性压力传感器具有抗损伤性。纤维 [33] [34] 和纺织品 [35] [36] [37] 具有上述基材所缺乏的优良透气性,被认为是最接近人体皮肤的天然材料。由于蚕丝 [38] [39] [40] 具有生物相容性、透光性、机械坚固性等诸多优点,已被广泛报道为柔性和可穿戴电子产品的衬底。

3.2. 传感材料

传感材料是设备感知外界压力刺激的关键部分。传统上,压阻式传感器基于刚性和脆性无机材料(如多晶硅金属和单晶硅以及氮化物材料),然而这些材料的机械灵活性非常有限。对于柔性可穿戴器件的应用,压阻式传感器需要具有高延展性和一致性,以及在宽应变范围内检测细微载荷的能力。最常用的导电材料是金属基材料(金属基材料(金属纳米颗粒 [41] [42] 和金属纳米线)、碳基材料(如炭黑 [43] [44] [45] 、碳纳米管 [46] [47] 和石墨烯 [48] [49] [50] )、导电聚合物(如聚吡咯(PPy) [51] [52] [53] [54] 、聚苯胺(PANI) [55] [56] [57] 和聚(苯乙烯磺酸酯) [PEDOT:PSS] [58] [59] [60] )和其他材料(如MOF和MXene [61] [62] )。这些活性材料表现出优异的机械性能、导电性和长期稳定性。

碳纳米管(CNT)基于其优良的导电性、高强度的拉伸性、独特的介电性质以及能够实。

现较好的透明性使其在柔性压力传感器的研究中受到了广泛关注。Lipomi等人 [37] 在PDMS薄膜上喷涂碳纳米管实现了透明的可拉伸导电薄膜,该薄膜能够承受150%的应变,并且在拉伸情况下电导率高达2200 S/cm,还将该透明导电薄膜作为柔性电极应用于电容器,实现了电容式柔性压力传感器阵列的制备,实现了器件的透明性。

石墨烯作为一种新型二维碳基材料,具备优良的光学、电学和力学性能,并且可与碳纳米管混合以改善性能,常作为柔性压力传感器的候选材料。石墨烯通常由氧化石墨烯(GO)还原得到,称之为还原氧化石墨烯(rGO)。Lou等人 [63] 将PVDF纳米纤维和rGO结合制备了柔性导电薄膜,PVDF提供了粘弹性,rGO提供了导电性,用两块PDMS夹住导电薄膜实现传感器的封装。研究表明该传感器具有15.6 kPa−1的高灵敏度,压力检测下限为1.2 Pa,响应时间为5 ms,工作电压为1 V,并且具有较好的循环稳定性。

3.3. 电极材料

柔性传感器件电极材料的选择必须考虑其机械柔性和稳定性。超薄电极适合于这种应用,因为它们可以承受弯曲力而不容易破坏导电路径。此外,为了消除断裂的可能性,有必要将电极结构设计成这样一种方式(如波浪结构、蛇形图案和螺旋弹簧),使其不会受到弯曲或扭曲作用力的影响。用作柔性电极的材料主要标准是高的导电性、与基底的良好粘附强度和对机械变形的很强的鲁棒性。通常,电极材料可分为四个部分,如金属、纳米材料、导电聚合物和导电织物。银(Ag)、金(Au)、镍(Ni)和铜(Cu)等金属是最常见的电极材料,而对于柔性应用,石墨烯、碳纳米管(CNTs)或金属纳米线(NWs)等纳米材料由于其高导电性和柔性而被广泛首选。互连的柔性和伸缩性也同样重要,因此,电路工程是必要的,以使器件在应变条件下稳定和长期持续。

4. 传感器的应用

4.1. 脉搏信号监测

Figure 6. (a) Structural and optical photograph of the conductive ion pressure sensor; (b) Photograph of the pressure sensor on the fingertip for pulse monitoring; (c) Pulse wave curves for different parts of the human body [66]

图6. (a) 导电离子压力传感器的结构和光学照片;(b) 压力传感器在指尖上用于脉搏监测的照片;(c) 人体不同部位的脉搏波曲线 [66]

脉搏波是在血液循环期间沿着动脉系统可检测到的重要生理现象,包含大量且可靠的信号。通过收集脉搏强度、频率和反射,专业医疗人员可以推断诸如血压(BP)、粘度、速度、血流阻力和血管壁状态的各种信息,从而提供心血管疾病的诊断和预防,可以在一定程度上映射出心脏与血管的健康状况 [64] [65] 。Lin课题组等人将工业织物浸泡在导电离子液体中5分钟,作为介电层,制备了一种灵敏度高、柔韧性强的导电离子压力传感器,如图6(a)所示,其线性灵敏度为13.5 kPa−1,响应迅速,在5000次加载/卸载循环中具有显著的稳定性。该工艺简单,高效,重复性好,适合工业化生产。如图6(b)所示,我们将制备的导电离子压力传感器用于监测手指处的脉搏信号,从脉搏信号的放大图能够清晰的在每个脉搏波周期中辨别出三个特征波形,可通过波形中的时值和幅值对动脉增强指数(AIr与P波和T波之间的时差(TDVP)进行计算以评估动脉健康状况。此外,我们还把压力传感器附着于人体不同的部位来进行脉搏信号的检测,如图6(c)所示,对人体不同部位脉搏信号的(肱动脉、胫骨后动脉、足动脉、颈动脉、颞动脉)测试曲线中均能检测到三个特征波形的存在。因此,柔性压力传感器在心血管疾病的辅助临床诊断中可发挥重要的作用 [66] 。

4.2. 足底压力检测和步态监测

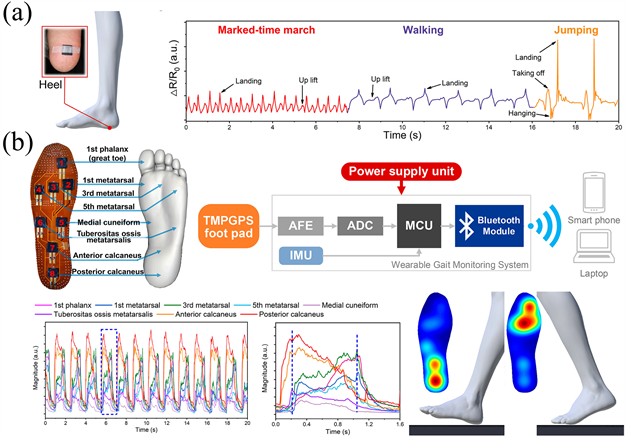

Figure 7. Triode like graphene pressure sensor for plantar pressure detection and gait monitoring [67] (a) Schematic and photograph of the sensor attached under the heel of the test subject and the detected foot pressure signal during various movements of marching, walking and jumping at the marked time; (b) Block diagram of the wearable gait monitoring system

图7. 用于足底压力检测和步态监测的仿三极管石墨烯压力传感器 [67] (a) 附在测试对象脚跟下的传感器的示意图和照片以及在标记时间的行进、行走和跳跃的各种运动期间检测到的脚压力信号;(b) 可穿戴步态监测系统框图

足部有人体第二心脏之称,具有多种特征信息。走路是人类的一个根本特征,是我们几乎每天都要做的事情。一个正常的走路步态,可以让人长时间舒适地行走,很容易在跑步和走路之间切换。但有些孩子在成长过程中存在步态问题(如扁平足、内/外八字、X/O腿、跟骨外翻等),需要做姿势评估和矫正,帮助孩子改善这些问题。此外,一些患有神经或肌肉疾病的人难以保持有规律的步幅。他们需要努力克服一些障碍,这样他们才能正常行走。因此,步行步态模式监测具有重要意义。如图7(a)所示,Wu等人将制备的传感器安装在脚后跟,可以实现在行走和跳跃的各种运动中检测到的足部压力信号 [67] 。此外,他们还开发了一种基于传感器的可穿戴鞋垫,以提供实时步态监测。如图7(b)所示,将几个仿三极管石墨烯压力传感器与柔性印刷电路板(PCB)连接到海绵鞋垫上,以制造压力传感阵列鞋垫。鞋垫的电阻变化通过模拟前端(AFE)中的惠斯通电桥转换为电压值,然后通过模数转换器(ADC)并与来自数字惯性监测单元(IMU)的信号一起由微控制单元(MCU)获取。数据经过处理后,将利用蓝牙模块和天线无线传输到手机、笔记本电脑等终端。由集成步态监测鞋垫收集的左脚足底压力数据显示为的连续部分和单循环部分。很明显,最大压力出现在志愿者的左脚跟骨下。

4.3. 声带振动检测

声带是人类发声的主要器官,人之所以能够在说话时发出不同的声音,与声带的振动情况密切相关。高灵敏的柔性压力传感器能够实现对声带振动的检测并分辨出振动的微小变化,在声带神经和喉发音功能监测中可发挥出重要的临床应用价值。同时,声带振动中包含大量的语言信息,因此还可利用声带振动信号的差异进行语音识别。如图8所示,Li等人将压力传感器贴附于喉咙处,当测试者读不同单词和内容时,传感器检测出的信号表现出不同的特征波形,而对于相同的发声内容的测试曲线则具有相同的特征波形,由此证明了传感器在语音识别中的潜在应用 [68] 。

Figure 8. (a)~(c) Monitoring the vocal fold vibration signal during vocalization by attaching the pressure transducer to the throat area [68]

图8. (a)~(c) 将压力传感器贴附于喉咙部位监测发声时的声带振动信号 [68]

5. 结论与展望

近年来,许多科研工作者围绕柔性压力传感器展开了研究,并取得了重大进展。在此基础上我们总结了压力传感器的研究进展,重点阐述了电阻式压力传感器,电容式压力传感器和压电式压力传感器的传感机理以及制备柔性压力传感器所需要的柔性基板材料,传感材料和电极材料,又介绍了评价传感器性能参数,例如传感范围、灵敏度和稳定性,最后介绍了柔性压力传感器在脉搏信号监测、呼吸检测和关节运动监测等领域的实际应用。

随着研究的深入,将赋予柔性压力传感器更多的功能,包括自愈合和生物兼容性等。未来的主要问题是如何将多种传感功能和电源集成到一个单一的技术器件中,比如开发类似人类皮肤的多功能集成系统,需要将多种电子元件和传感器集成到小的软基板上,从而需要大面积、低成本的集成和制造技术。同时多功能化的传感器将产生大量电信号信息,如何收集和维护这些数量庞大的信号,以及如何保证集成式传感器的功能性和长期稳定性还需要进一步探讨。

文章引用

黄鹏举. 柔性压力传感器及其应用研究进展

Research Progress on Flexible Pressure Sensors and Their Applications[J]. 物理化学进展, 2023, 12(02): 99-111. https://doi.org/10.12677/JAPC.2023.122012

参考文献

- 1. Lin, X.Z., Gao, S., Fei, T., et al. (2019) Study on a Paper-Based Piezoresistive Sensor Applied to Monitoring Human Physiological Signals. Sensors and Actuators A: Physical, 292, 66-70. https://doi.org/10.1016/j.sna.2019.04.009

- 2. Lin, X.Z., Zhang, T., Cao, J.H., et al. (2020) Flexible Piezoresistive Sensors based on Conducting Polymer-Coated Fabric Applied to Human Physiological Signals Monitoring. Journal of Bionic Engineering, 17, 55-63. https://doi.org/10.1007/s42235-020-0004-9

- 3. Zhao, Y.N., Liu, L., Li, Z., et al. (2021) Facile Fabrication of Highly Sensitive and Durable Cotton Fabric-Based Pressure Sensors for Motion and Pulse Monitoring. Journal of Materials Chemistry C, 9, 12605-12614. https://doi.org/10.1039/D1TC02251B

- 4. Choi, S., Yoon, K., Lee, S., et al. (2019) Conductive Hierarchical Hairy Fibers for Highly Sensitive, Stretchable, and Water-Resistant Multimodal Gesture-Distinguishable Sensor, VR Applications. Advanced Functional Materials, 29, e1905808. https://doi.org/10.1002/adfm.201905808

- 5. Sakhuja, N., Kumar, R., Katare, P. and Bhat, N. (2022) Structure-Driven, Flexible, Multilayered, Paper-Based Pressure Sensor for Human—Machine Interfacing. ACS Sustainable Chemistry & Engineering, 10, 9697-9706. https://doi.org/10.1021/acssuschemeng.1c08491

- 6. Xu, Y.D., Sun, B.H., Ling, Y., et al. (2020) Multiscale Porous Elastomer Substrates for Multifunctional on-Skin Electronics with Passive-Cooling Capabilities. Proceedings of the National Academy of Sciences of the United States of America, 117, 205-213. https://doi.org/10.1073/pnas.1917762116

- 7. Yang, J., Li, H., Cheng, J.L., et al. (2021) Nanocellulose Intercalation to Boost the Performance of MXene Pressure Sensor for Human Interactive Monitoring. Journal of Materials Science, 56, 13859-13873. https://doi.org/10.1007/s10853-021-05909-y

- 8. Li, L., Fu, X.Y., Chen, S., et al. (2020) Hydrophobic and Stable MXene-Polymer Pressure Sensors for Wearable Electronics. ACS Applied Materials & Interfaces, 12, 15362-15369. https://doi.org/10.1021/acsami.0c00255

- 9. Shu, J., Gao, L., Li, Y., et al. (2022) MXene/Tissue Paper Composites for Wearable Pressure Sensors and Thermotherapy Electronics. Thin Solid Films, 743, Article ID: 139054. https://doi.org/10.1016/j.tsf.2021.139054

- 10. Tan, Y.S., Ivanov, K., Mei, Z.Y., et al. (2021) A Soft Wearable and Fully-Textile Piezoresistive Sensor for Plantar Pressure Capturing. Micromachines (Basel), 122. https://doi.org/10.21203/rs.3.rs-115752/v1

- 11. Chang, T.H., Tian, Y., Li, C.S., et al. (2019) Stretchable Graphene Pressure Sensors with Shar-Pei-Like Hierarchical Wrinkles for Collision-Aware Surgical Robotics. ACS Applied Materials & Interfaces, 11, 10226-10236. https://doi.org/10.1021/acsami.9b00166

- 12. Guo, Y., Guo, Z.Y., Zhong, M.J., et al. (2018) A Flexible Wearable Pressure Sensor with Bioinspired Microcrack and Interlocking for Full-Range Human-Machine Interfacing. Small, 14, e1803018. https://doi.org/10.1002/smll.201803018

- 13. Wang, F.X., Wang, M.J., Liu, H.C., et al. (2020) Multifunctional Self-Powered E-Skin with Tactile Sensing and Visual Warning for Detecting Robot Safety. Advanced Materials Interfaces, 7, e2000536. https://doi.org/10.1002/admi.202000536

- 14. Wang, X.C., Tang, Y.K., Cheng, S.R., et al. (2022) PDMS-Based Conductive Elastomeric Composite with 3D Reduced Graphene Oxide Conductive Network for Flexible Strain Sensor. Composites Part A: Applied Science and Manufacturing, 161, Article ID: 107113. https://doi.org/10.1016/j.compositesa.2022.107113

- 15. Wu, R.H., Ma, L.Y., Patil, A., et al. (2019) All-Textile Electronic Skin Enabled by Highly Elastic Spacer Fabric and Conductive Fibers. ACS Applied Materials & Interfaces, 11, 33336-33346. https://doi.org/10.1021/acsami.9b10928

- 16. Yu, C.X., Liu, K., Xu, J.W., et al. (2023) High-Performance Multifunctional Piezoresistive/Piezoelectric Pressure Sensor with Thermochromic Function for Wearable Monitoring. Chemical Engineering Journal, 459, Article ID: 141648. https://doi.org/10.1016/j.cej.2023.141648

- 17. Michel, T.R., Capasso, M.J., Cavusoglu, M.E., et al. (2019) Evaluation of Porous Polydimethylsiloxane/Carbon Nanotubes (PDMS/CNTs) Nanocomposites as Piezoresistive Sensor Materials. Microsystem Technologies, 26, 1101-1112. https://doi.org/10.1007/s00542-019-04636-4

- 18. Riyajuddin, S., Kumar, S., Gaur, S.P., et al. (2020) Linear Piezoresistive Strain Sensor Based on Graphene/g-C3N4/ PDMS Heterostructure. Nanotechnology, 31, Article 295501. https://doi.org/10.1088/1361-6528/ab7b88

- 19. Zhang, Z.N., Weng, L., Guo, K., et al. (2022) Durable and Highly Sensitive Flexible Sensors for Wearable Electronic Devices with PDMS-MXene/TPU Composite Films. Ceramics International, 48, 4977-4985. https://doi.org/10.1016/j.ceramint.2021.11.035

- 20. Huang, C.B., Witomska, S., Aliprandi, A., et al. (2019) Molecule-Graphene Hybrid Materials with Tunable Mechanoresponse: Highly Sensitive Pressure Sensors for Health Monitoring. Advanced Materials, 31, e1804600. https://doi.org/10.1002/adma.201804600

- 21. Liu, W.J., Liu, N.S., Yue, Y., et al. (2018) Piezoresistive Pressure Sensor Based on Synergistical Innerconnect Polyvinyl Alcohol Nanowires/Wrinkled Graphene Film. Small, 14, e1704149. https://doi.org/10.1002/smll.201704149

- 22. Piro, L., Lamanna, L., Guido, F., et al. (2021) Flexible SAW Microfluidic Devices as Wearable pH Sensors Based on ZnO Nanoparticles. Nanomaterials (Basel), 11, Article ID: 1479. https://doi.org/10.3390/nano11061479

- 23. Wang, R.J., Tan, Z.Q., Zhong, W.B., et al. (2020) Polypyrrole (PPy) Attached on Porous Conductive Sponge Derived from Carbonized Graphene Oxide Coated Polyurethane (PU) and Its Application in Pressure Sensor. Composites Communications, 22, Article ID: 100426. https://doi.org/10.1016/j.coco.2020.100426

- 24. Chen, X.T., Liu, C.G., Liu, S., Lyu, B. and Li, D.L. (2018) A High Compressibility Pressure—Sensitive Structure Based on CB@PU Yarn Network. Sensors, 18, Article 4141. https://doi.org/10.3390/s18124141

- 25. Lv, Y.H., Min, L.Z., Niu, F.X., et al. (2022) Wrinkle-Structured MXene Film Assists Flexible Pressure Sensors with Superhigh Sensitivity and Ultrawide Detection Range. Nanocomposites, 8, 81-94. https://doi.org/10.1080/20550324.2022.2054211

- 26. Cheng, H.N., Zhang, N.Y., Yin, Y.J. and Wang, C.X. (2021) A High-Performance Flexible Piezoresistive Pressure Sensor Features an Integrated Design of Conductive Fabric Electrode and Polyurethane Sponge. Macromolecular Materials and Engineering, 306, e2100263. https://doi.org/10.1002/mame.202100263

- 27. Zheng, Y., Jin, Q., Chen, W.Y., Suna, Y. and Wang, Z.Q. (2019) High Sensitivity and Wide Sensing Range of Stretchable Sensors with Conductive Microsphere Array Structures. Journal of Materials Chemistry C, 27, 8423-8431. https://doi.org/10.1039/C9TC02698C

- 28. Ji, B., Zhou, Q., Wu, J.B., Gao, Y.B., Wen, W.J. and Zhou, B.P. (2020) Synergistic Optimization toward the Sensitivity and Linearity of Flexible Pressure Sensor via Double Conductive Layer and Porous Microdome Array. ACS Applied Materials & Interfaces, 12, 31021-31035. https://doi.org/10.1021/acsami.0c08910

- 29. Wang, H.H., Cen, Y.M. and Zeng, X.Q. (2021) Highly Sensitive Flexible Tactile Sensor Mimicking the Microstructure Perception Behavior of Human Skin. ACS Applied Materials & Interfaces, 13, 28538-28545. https://doi.org/10.1021/acsami.1c04079

- 30. Cheng, L.X., Wang, R.X., Hao, X.J. and Liu, G.C. (2021) Design of Flexible Pressure Sensor Based on Conical Microstructure PDMS-Bilayer Graphene. Sensors (Basel), 21, Article 289. https://doi.org/10.3390/s21010289

- 31. Yang, J.C., Kim, J.O., Oh, J.W., et al. (2019) Microstructured Porous Pyramid-Based Ultrahigh Sensitive Pressure Sensor Insensitive to Strain and Temperature. ACS Applied Materials & Interfaces, 11, 19472-19480. https://doi.org/10.1021/acsami.9b03261

- 32. Lin, X.Z., Li, F., Bing, Y., Fei, T., Liu, S., Zhao, H. and Zhang, T. (2021) Biocompatible Multifunctional E-Skins with Excellent Self-Healing Ability Enabled by Clean and Scalable Fabrication. Nano-Micro Letters, 13, Article No. 200. https://doi.org/10.1007/s40820-021-00701-8

- 33. Zhang, H., Sun, X.H., Hubbe, M. and Pal, L. (2019) Flexible and Pressure-Responsive Sensors from Cellulose Fibers Coated with Multiwalled Carbon Nanotubes. ACS Applied Electronic Materials, 1, 1179-1188. https://doi.org/10.1021/acsaelm.9b00182

- 34. Cho, S.Y., Yu, H., Choi, J., et al. (2019) Continuous Meter-Scale Synthesis of Weavable Tunicate Cellulose/Carbon Nanotube Fibers for High-Performance Wearable Sensors. ACS Nano, 13, 9332-9341. https://doi.org/10.1021/acsnano.9b03971

- 35. Chen, F.C., Liu, H.J., Xu, M.T., et al. (2022) Fast-Response Piezoresistive Pressure Sensor Based on Polyaniline Cotton Fabric for Human Motion Monitoring. Cellulose, 29, 6983-6995. https://doi.org/10.1007/s10570-022-04661-z

- 36. Zhang, X.P., Ke, L.W., Zhang, X.M., et al. (2022) Breathable and Wearable Strain Sensors Based on Synergistic Conductive Carbon Nanotubes/Cotton Fabrics for Multi-directional Motion Detection. ACS Applied Materials & Interfaces, 14, 25753-25762. https://doi.org/10.1021/acsami.2c04790

- 37. Li, Z., Chen, X., Chen, X., et al. (2022) Interfacial-Modified Graphene/Cotton Fabric for Durable Pressure Sensor via Electrostatic Self-Assembly. ACS Applied Polymer Materials, 4, 8604-8612. https://doi.org/10.1021/acsapm.2c01530

- 38. Liu, Z.L., Wang, J.X., Zhang, Q., et al. (2022) Electrospinning Silk Fibroin/Graphene Nanofiber Membrane Used for 3D Wearable Pressure Sensor. Polymers (Basel), 14, Article 3875. https://doi.org/10.3390/polym14183875

- 39. He, Y.X., Zhou, M.Y., Mahmoud, M.H.H., et al. (2022) Multifunctional Wearable Strain/Pressure Sensor Based on Conductive Carbon Nanotubes/Silk Nonwoven Fabric with High Durability and Low Detection Limit. Advanced Composites and Hybrid Materials, 5, 1939-1950. https://doi.org/10.1007/s42114-022-00525-z

- 40. Wang, Y.J., Wang, Y., Xu, M.T., Dai, F.Y. and Li, Z. (2022) Flat Silk Cocoon Pressure Sensor Based on a Sea Urchin-like Microstructure for Intelligent Sensing. ACS Sustainable Chemistry & Engineering, 10, 17252-17260. https://doi.org/10.1021/acssuschemeng.2c05540

- 41. Soe, H.M., Abd Manaf, A., Matsuda, A. and Jaafar, A. (2021) Performance of a Silver Nanoparticles-Based Polydimethylsiloxane Composite Strain Sensor Produced Using Different Fabrication Methods. Sensors and Actuators A: Physical, 329, Article ID: 112793. https://doi.org/10.1016/j.sna.2021.112793

- 42. Soe, H.M., Manaf, A.A., Matsuda, A. and Jaafar, A. (2020) Development and Fabrication of Highly Flexible, Stretchable, and Sensitive Strain Sensor for Long Durability Based on Silver Nanoparticles—Polydimethylsiloxane Composite. Journal of Materials Science: Materials in Electronics, 31, 11897-11910. https://doi.org/10.1007/s10854-020-03744-6

- 43. Chen, T.J., Wu, G.Z., Panahi-Sarmad, M., et al. (2022) A Novel Flexible Piezoresistive Sensor Using Superelastic Fabric Coated with Highly Durable SEBS/TPU/CB/CNF Nanocomposite for Detection of Human Motions. Composites Science and Technology, 227, Article ID: 109563. https://doi.org/10.1016/j.compscitech.2022.109563

- 44. Huang, L.T., Chen, J.W., Xu, Y.Q., et al. (2021) Three-Dimensional Light-Weight Piezoresistive Sensors Based on Conductive Polyurethane Sponges Coated with Hybrid CNT/CB Nanoparticles. Applied Surface Science, 548, Article ID: 149268. https://doi.org/10.1016/j.apsusc.2021.149268

- 45. Meng, J.J., Pan, P., Yang, Z.C., et al. (2020) Degradable and Highly Sensitive CB-Based Pressure Sensor with Applications for Speech Recognition and Human Motion Monitoring. Journal of Materials Science, 55, 10084-10094. https://doi.org/10.1007/s10853-020-04707-2

- 46. Su, X.J., Luo, C.L., Yan, W.G., Jiao, J.Y. and Zhong, D.Z. (2021) Microdome-Tunable Graphene/Carbon Nanotubes Pressure Sensors Based on Polystyrene Array for Wearable Electronics. Materials (Basel), 14, Article 7385. https://doi.org/10.3390/ma14237385

- 47. Hur, O.N., Ha, J.H. and Park, S.H. (2020) Strain-Sensing Properties of Multi-Walled Carbon Nanotube/Polydimethyl- siloxane Composites with Different Aspect Ratio and Filler Contents. Materials (Basel), 13, Article 2431. https://doi.org/10.3390/ma13112431

- 48. Li, Y., Cui, Y.G., Zhang, M.J., et al. (2022) Ultrasensitive Pressure Sensor Sponge Using Liquid Metal Modulated Nitrogen-Doped Graphene Nanosheets. Nano Letters, 22, 2817-2825. https://doi.org/10.1021/acs.nanolett.1c04976

- 49. Yin, Y.M., Wang, Y.L., Li, H.Y., et al. (2022) A Flexible Dual Parameter Sensor with Hierarchical Porous Structure for Fully Decoupled Pressure—Temperature Sensing. Chemical Engineering Journal, 430, Article ID: 133158. https://doi.org/10.1016/j.cej.2021.133158

- 50. Yao, W.Q., Mao, R.W., Gao, W.W., et al. (2020) Piezoresistive Effect of Superelastic Graphene Aerogel Spheres. Carbon, 158, 418-425. https://doi.org/10.1016/j.carbon.2019.11.005

- 51. Zhao, P.F., Zhang, R., Tong, Y.H., Zhao, X.L., Tang, Q.X. and Liu, Y.C. (2020) All-Paper, All-Organic, Cuttable, and Foldable Pressure Sensor with Tuneable Conductivity Polypyrrole. Advanced Electronic Materials, 6, e1901426. https://doi.org/10.1002/aelm.201901426

- 52. Tai, H.H., Chen, B.A., Liu, Y.H., Lu, Y.J. and Wang, J.C. (2022) Submillimeter-Scaled PEDOT: PSS/PPy Piezoresistive Pressure Sensor Array and Its Applications in Biomedicine. IEEE Sensors Journal, 22, 6418-6425. https://doi.org/10.1109/JSEN.2022.3153002

- 53. Veeralingam, S., Praveen, S., Vemula, M. and Badhulika, S. (2022) One-Step Synthesis of Carbon-Doped PPy Nanoparticles Interspersed in 3D Porous Melamine Foam as a High-Performance Piezoresistive Pressure, Strain, and Breath Sensor. Materials Chemistry Frontiers, 65, 570-579. https://doi.org/10.1039/D1QM01427G

- 54. Wang, X.J., Gao, X.Y., Wang, X.Y., et al. (2022) Development of High-Sensitivity Piezoresistive Sensors Based on Highly Breathable Spacer Fabric with TPU/PPy/PDA Coating. Polymers (Basel), 14, Article 859. https://doi.org/10.3390/polym14050859

- 55. Yin, T.T., Cheng, Y.F., Hou, Y.X., et al. (2022) 3D Porous Structure in MXene/PANI Foam for a High-Performance Flexible Pressure Sensor. Small, 18, e2204806. https://doi.org/10.1002/smll.202204806

- 56. Dong, X., Ge, Y., Li, K., et al. (2022) A High-Pressure Resistant Ternary Network Hydrogel Based Flexible Strain Sensor with a Uniaxially Oriented Porous Structure toward Gait Detection. Soft Matter, 18, 9231-9241. https://doi.org/10.1039/D2SM01286C

- 57. Xu, L., Liu, C., Ma, X., et al. (2023) Two-Birds-One-Stone: Flexible PANI Film with Bionic Microstructures for Multifunctional Sensing of Physical and Chemical Stimuli. Chemical Engineering Journal, 451, Article ID: 138820. https://doi.org/10.1016/j.cej.2022.138820

- 58. Ko, Y.S., Kim, J., Kim, D., et al. (2019) Fabrication of Highly Conductive Porous Cellulose/PEDOT: PSS Nanocomposite Paper via Post-Treatment. Nanomaterials (Basel), 9, Article 612. https://doi.org/10.3390/nano9040612

- 59. Yang, T. and Mativetsky, J.M. (2019) Paper-Based Mechanical Sensors Enabled by Folding and Stacking. ACS Applied Materials & Interfaces, 11, 26339-26345. https://doi.org/10.1021/acsami.9b06071

- 60. Zhang, M., Wang, Y.X., Liu, K., et al. (2023) Strong, Conductive, and Freezing-Tolerant Polyacrylamide/PEDOT: PSS/Cellulose Nanofibrils Hydrogels for Wearable Strain Sensors. Carbohydrate Polymers, 305, Article ID: 120567. https://doi.org/10.1016/j.carbpol.2023.120567

- 61. Zhao, J., Gao, J., Zhou, Z., et al. (2021) Highly Responsive Asymmetric Pressure Sensor Based on MXene/Reduced Graphene Oxide Nanocomposite Fabricated by Laser Scribing Technique. IEEE Sensors Journal, 21, 26673-26680. https://doi.org/10.1109/JSEN.2021.3124847

- 62. Lee, H.J., Yang, J.C., Choi, J., et al. (2021) Hetero-Dimensional 2D Ti3C2Tx MXene and 1D Graphene Nanoribbon Hybrids for Machine Learning-Assisted Pressure Sensors. ACS Nano, 15, 10347-10356. https://doi.org/10.1021/acsnano.1c02567

- 63. Lou, Z., Chen, S., Wang, L.L., Jiang, K. and Shen, G.Z. (2016) An Ultra-Sensitive and Rapid Response Speed Graphene Pressure Sensors for Electronic Skin and Health Monitoring. Nano Energy, 23, 7-14. https://doi.org/10.1016/j.nanoen.2016.02.053

- 64. He, J., Xiao, P., Lu, W., et al. (2019) A Universal High Accuracy Wearable Pulse Monitoring System via High Sensitivity and Large Linearity Graphene Pressure Sensor. Nano Energy, 59, 422-433. https://doi.org/10.1016/j.nanoen.2019.02.036

- 65. Omboni, S., Posokhov, I.N., Kotovskaya, Y.V., et al. (2016) Twenty-Four-Hour Ambulatory Pulse Wave Analysis in Hypertension Management: Current Evidence and Perspectives. Current Hypertension Reports, 18, Article No. 72. https://doi.org/10.1007/s11906-016-0681-2

- 66. Lin, Q.P., Huang, J., Yang, J.L., et al. (2020) Highly Sensitive Flexible Iontronic Pressure Sensor for Fingertip Pulse Monitoring. Advanced Healthcare Materials, 9, e2001023. https://doi.org/10.1002/adhm.202001023

- 67. Wu, Q., Qiao, Y.C., Guo, R., et al. (2020) Triode-Mimicking Graphene Pressure Sensor with Positive Resistance Variation for Physiology and Motion Monitoring. ACS Nano, 14, 10104-10114. https://doi.org/10.1021/acsnano.0c03294

- 68. Li, X., Fa, Y.J., Li, H.Y., et al. (2020) Ultracomfortable Hierarchical Nanonetwork for Highly Sensitive Pressure Sensor. ACS Nano, 14, 9605-9612. https://doi.org/10.1021/acsnano.9b10230