Instrumentation and Equipments

Vol.

11

No.

02

(

2023

), Article ID:

68317

,

5

pages

10.12677/IaE.2023.112024

GDX1铝箔纸传动轴油封故障分析与处理

朱柏橙,蒋红祥,曹斌,魏明,吴恒文

红塔烟草(集团)有限责任公司玉溪卷烟厂,云南 玉溪

收稿日期:2023年5月22日;录用日期:2023年6月23日;发布日期:2023年6月30日

摘要

GDX1卷烟包装机是一种高效、自动化的卷烟包装设备,它可以完成对卷烟的分类、整形、包装、封口等一系列工艺流程。该设备具有多项特点,如:生产效率高、稳定可靠、操作简单、维修方便等。此外,GDX1卷烟包装机还具有出色的包装质量,能够确保每个卷烟包装整齐、美观、卫生,符合卷烟行业的相关标准要求。该设备采用PLC控制技术,配备了触摸屏操作界面,可实现人机交互,方便快捷。同时,设备采用进口电器元件和高品质传动部件、气动元件等重要部分,确保了设备的稳定性和寿命,并且同时提高了整个包装过程的工作效率。因此GDX1包装机是目前玉溪卷烟厂较长时间以来的主流机型。随着时代的进步,包装机械的飞速发展,卷烟产品包装质量的要求越来越高,其中的好多机械零部件都需要进行改进,其中铝箔纸输送组件就由原来的摩擦输送改为现在的负压输送,而原来的组件拆除后,剩下旋转轴,其上的油脂密封件长时间使用后就会消磨掉,导致此处油脂漏油,而原有结构要更换此油脂密封件需要从内部拆卸,要打开整个传动箱从主传动箱内拆除紧固件、垫片、传动齿及密封垫圈,才能从前方拆卸出此处传动轴。针对此处油脂密封件的更换,本文提出在不影响其他零部件的基础上对传动轴进行改进加工,使得更换油脂密封件时直接从外部拆卸即可,节省更换油脂密封件的时间,提高机械设备效率。

关键词

GDX1,铝箔纸输送,油脂密封件漏油,拆卸方式

Analysis and Treatment of Transmission Shaft Oil Leakage Failure of GDX1 Liner Conveying Assembly

Bocheng Zhu, Hongxiang Jiang, Bin Cao, Ming Wei, Hengwen Wu

Hongta Tobacco (Group) Co., Ltd. Yuxi Cigarette Factory, Yuxi Yunnan

Received: May 22nd, 2023; accepted: Jun. 23rd, 2023; published: Jun. 30th, 2023

ABSTRACT

GDX1 cigarette packaging machine is an efficient and automatic cigarette packaging equipment, which can complete a series of technological processes such as classification, shaping, packaging and sealing of cigarettes. The equipment has a number of characteristics, such as: high production efficiency, stable and reliable, simple operation, easy maintenance and so on. In addition, the GDX1 cigarette packaging machine has excellent packaging quality, which ensures that each cigarette package is neat, beautiful and hygienic, in line with the relevant standards and requirements of the cigarette industry. The device adopts PLC control technology, equipped with touch screen operation interface, can realize man-machine interaction, convenient and fast. At the same time, the equipment adopts imported electrical components, high-quality transmission components, pneumatic components and other important parts, to ensure the stability and life of the equipment, and at the same time improve the efficiency of the whole packaging process. Therefore, GDX1 packaging machine is the mainstream model of Yuxi Cigarette Factory for a long time. With the progress of The Times, the rapid development of packaging machinery, cigarette product packaging quality requirements are becoming higher and higher, a lot of mechanical parts need to be improved, among which aluminum foil conveying components from the original friction conveying to the current negative pressure conveying, and the original components removed, the remaining rotating shaft, the grease seals will be worn away after a long time of use, Resulting in oil leakage here, and the original structure to replace the oil seals need to be removed from the inside, to open the whole transmission box from the main transmission box to remove fasteners, gaskets, transmission gear and sealing gaskets, in order to remove the drive shaft from the front. In view of the replacement of the grease seal here, this paper proposes to improve the processing of the drive shaft without affecting other parts, so that the replacement of the grease seal can be directly removed from the outside, saving the time of replacing the grease seal and improving the efficiency of mechanical equipment.

Keywords:GDX1, Inner Liner Conveying, Oil Seal Leaking, Disassembly Mode

Copyright © 2023 by author(s) and Hans Publishers Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY 4.0).

http://creativecommons.org/licenses/by/4.0/

1. 引言

GDX1卷烟包装机是一种高效、自动化的卷烟包装设备,它可以完成对卷烟的分类、整形、包装、封口等一系列工艺流程。该设备具有多项特点,如:生产效率高、稳定可靠、操作简单、维修方便等。此外,GDX1卷烟包装机还具有出色的包装质量,能够确保每个卷烟包装整齐、美观、卫生,符合卷烟行业的相关标准要求。该设备采用PLC控制技术,配备了触摸屏操作界面,可实现人机交互,方便快捷。同时,设备采用进口电器元件和高品质传动部件、气动元件等重要部分,确保了设备的稳定性和寿命,并且同时提高了整个包装过程的工作效率。GDX1卷烟包装机是卷烟生产企业提高生产效率、减少人工干预、提升产品包装质量的理想选择。GDX1包装机长时间运行后,铝箔纸传动轴上的油脂密封件时间长就会磨损,导致油脂密封件损坏,更换传动轴严重影响设备效率。

2. 现状调查及原因分析

2.1. 现状调查

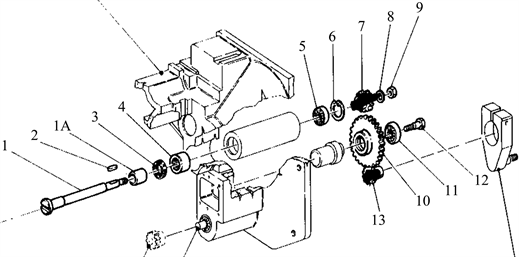

GDX1包装机长时间运行后,铝箔纸传动轴上的油脂密封件时间长就会磨损,导致油脂密封件损坏,更换传动轴严重影响设备效率。铝箔纸传递旋转轴结构 [1] [2] [3] [4] 如图1所示,对生产车间的GDX1包装机进行了详细跟踪与调查,2022年2月~4月设备更换铝箔纸传动旋转轴的油脂密封件次数进行统计如表1所示。

1——轴;2——键(4 × 6 × 12);3——油脂密封件(22 × 32 × 7);4——滚动轴承(NK22/16, 22 × 30 × 16);5——滚动轴承(RIV6201, 12 × 32 × 10);6——垫圈(32);7——齿轮;8——垫圈(10.5);9——螺母(M10 × 6)

1——轴;2——键(4 × 6 × 12);3——油脂密封件(22 × 32 × 7);4——滚动轴承(NK22/16, 22 × 30 × 16);5——滚动轴承(RIV6201, 12 × 32 × 10);6——垫圈(32);7——齿轮;8——垫圈(10.5);9——螺母(M10 × 6)

Figure 1. Breakdown diagram of the drive shaft of the lining conveying assembly

图1. 铝箔纸输送组件传动轴分解图

Table 1. Statistical table of replacement times of grease seals for aluminum foil conveying components

表1. 铝箔纸输送组件更换油脂密封件次数统计表

从统计表可以看出:3月份处理铝箔纸输送组件传动轴漏油2次,耗时12小时;4月份处理铝箔纸输送组件传动轴漏油1次,耗时6小时;5月份处理铝箔纸输送组件传动轴漏油2次,耗时12小时;更换该组件油脂密封件严重影响设备效率。

2.2. 原因分析

经分析,在拆卸更换漏油油脂密封件时,需要从主传动箱内拆除紧固件、垫片、传动齿及密封垫圈才能从前方拆除此传动轴,更换油脂密封件,更换好油脂密封件后安装紧固件、垫片、传动齿及密封垫圈后安装传动箱防护盖板耗时很长,主要原因在于需要从内部进行拆除。通过对传动轴进行改造加工处理,改变传动轴的拆卸方式,改造后从机器外面直接更换油脂密封件可以控制在20分钟内。

3. 解决方案及实施

油脂密封件所在的传动组件,其中传动轴因轴头有一轴阶(如图2),原来的油脂密封件只能在拆卸出整根传动轴后更换,为了实现从外面进行更换油脂密封件的目的,必须对传动组件上轴阶进行加工,以使油脂密封件能从外面传动轴端部方向直接套到轴上 [5] ,通过测量得知轴头直径25毫米,而油脂密封件尺寸为:22 × 32 × 7 mm,因此必须要把轴头加工至少到直径22毫米。这样轴头不再起传动作用,可调节的空间不受限制,这样油脂密封件更容易放入。

Figure 2. Transmission diagram before machining

图2. 加工前传动图

对GDX1包装机铝箔纸传送机构传动轴漏油,决定在GDX1包装机上实施以上方案。在拆除传动组件后,为了实现从外部进行更换油脂密封件的目的,对轴阶进行加工,使油脂密封件能从外面轴端方向直接套到轴上。通过测量得知轴头直径为25毫米,而油脂密封件尺寸为:22 × 32 × 7 mm,必须要把轴肩直径加工到不大于22毫米。加工后轴头不再起传动作用,这样油脂密封件更容易放入。加工后的轴如图3所示。

Figure 3. Transmission diagram after machining

图3. 加工前传动图

4. 实验验证

按照文中所确定的改造方式,对铝箔纸传递机构的传动轴改造完成后,对修理人员更换传动轴时间进行统计,如表2所示。

Table 2. Statistical table of the time for the repair personnel to replace the drive shaft

表2. 修理人员更换传动轴时间统计表

从上表可以看出:铝箔纸传递机构旋转轴按照文中所描述的方式改进后,更换传动轴油脂密封件,更换时间平均为20分钟,如表3所示。

Table 3. Comparison table of time for repair personnel to replace the drive shaft

表3. 修理人员更换传动轴时间对照表

5. 结论

通过对GDX1铝箔纸输送传动轴油脂密封件漏油故障的分析,对相应的传动轴结构进行改进,改善油脂密封件的拆装方式,有效地将油脂密封件漏油故障处理时间由原来的2小时缩短到20分钟,极大地提高了故障处理效率,对设备净效率的整体提升具有重要意义。

文章引用

朱柏橙,蒋红祥,曹 斌,魏 明,吴恒文. GDX1铝箔纸传动轴油封故障分析与处理

Analysis and Treatment of Transmission Shaft Oil Leakage Failure of GDX1 Liner Conveying Assembly[J]. 仪器与设备, 2023, 11(02): 177-181. https://doi.org/10.12677/IaE.2023.112024

参考文献

- 1. 董祥云. GDX1机组[M]. 中国科学技术出版社, 2001.

- 2. 王栋梁. 机械基础[M]. 北京: 中国劳动出版社, 1993.

- 3. 濮良贵, 纪明刚. 机械设计[M]. 北京: 高等教育出版社, 2006.

- 4. 孙桓, 陈作模. 机械原理[M]. 北京: 高等教育出版社, 2000.

- 5. 温亮, 吴德成, 李正伟. GDX1主机出口转盘传动轴的改进分析[J]. 中国设备工程, 2021(20): 95-97.