Hans Journal of Nanotechnology

Vol.

12

No.

04

(

2022

), Article ID:

58502

,

13

pages

10.12677/NAT.2022.124037

过渡金属基电催化剂在全解水反应中的动力学调控策略

许国栋,冯明月,王诗雨,程煜,张莉芳*

南通大学化学化工学院,江苏 南通

收稿日期:2022年8月29日;录用日期:2022年11月20日;发布日期:2022年11月29日

摘要

过渡金属(TM)基催化剂因其在水分解中的独特优势而被广泛研究。尽管目前国内外取得了重大进展,但TM基材料在电催化中的有效动力学调控策略仍处于初始阶段。通过在TM基催化剂中引入异质成分,形成特定的界面,有利于调整催化剂界面环境和化学吸附行为,从而加速动力学过程。在这篇综述中,我们全面总结了TM基电催化剂的动力学调控策略,包括界面工程、缺陷工程、掺杂工程和晶面工程,并且在全文最后概述了这一新兴领域当前面临的机遇与挑战。

关键词

过渡金属基电催化剂,氢能,电催化水分解,高效动力学

Kinetic Regulation Strategies of Transition-Metal-Based Electrocatalysts in Water Splitting Reaction

Guodong Xu, Mingyue Feng, Shiyu Wang, Yu Cheng, Lifang Zhang*

School of Chemistry and Chemical Engineering, Nantong University, Nantong Jiangsu

Received: Aug. 29th, 2022; accepted: Nov. 20th, 2022; published: Nov. 29th, 2022

ABSTRACT

Transition Metal (TM)-based catalysts are widely studied for their unique advantages in water splitting. Despite significant progress, efficient kinetic regulation strategies for TM-based materials in electrocatalysis and real-time monitoring of the dynamic evolution of reaction processes are still in the initial stages. By introducing heterogeneous components into the TM-based catalyst and forming a specific interface, it is beneficial to adjust the catalyst interface environment and chemical adsorption behavior, thereby accelerating the kinetic process. In this review, the kinetic regulation strategies of TM-based electrocatalysts are timely and comprehensively summarized, including interface engineering, defect engineering, doping engineering and crystal face engineering. Finally, we outline the current challenges and identify the opportunities facing this emerging area.

Keywords:Transition-Metal-Based Electrocatalysts, Hydrogen Energy, Electrocatalytic Water Splitting, High Efficient Kinetic

Copyright © 2022 by author(s) and Hans Publishers Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY 4.0).

http://creativecommons.org/licenses/by/4.0/

1. 引言

高纯度氢气因其可再生性和碳中和性 [1],被认为是一种前景广阔的下一代能源,而高纯度绿色氢气的大规模生产是制约燃料电池产业发展和实现碳中和蓝图的关键因素 [2]。目前的氢气(H2)大多是通过化石资源的蒸汽重整产生的 [3],存在着很多资源与环境问题。清洁、可再生和高效的H2发电技术是成功实现氢经济、不增加更多环保问题的技术保障 [2] [3] [4]。光解水或电解水产生的H2和O2被认为是替代化石燃料的可持续、高效和清洁的战略 [3] [4] [5],因为在这过程中,水既是唯一的起始分子,也是氢经济循环中的副产品 [4] [5] [6],H2燃烧的同时,释放能量并重新产生水 [7]。1789年首次报道了水的分裂:H2O(l) → H2(g) +1/2O2(g),ΔG = +237.2 kJ∙mol−1 [8],ΔE = 1.23 V相对于正常氢气电极(NHE),其包括两个半反应:阳极析氧反应(OER, 2H2O(l) →4e− + 4H+(aq) + O2(g))和阴极析氢反应(HER, 2H+(aq) + 2e−→ H2(g)) [6] [7] [8] [9]。虽然理论上电解水的分解电压为1.23 V,但实际上需要更高的电压来克服电化学过程中的障碍,这被称为过电位(η) [2] [4] [8]。大的过电位来自于OER和HER:阳极缓慢的四电子转移动力学以及阴极相当容易的二电子转移动力学。因此,为HER和OER过程设计的高效电催化剂更有利于克服大的水分解过电位,促进水分解过程,优化能量损失。

为了满足工业电解水的应用,电催化剂的设计必须遵循两个原则:一方面,电催化剂必须具有优良的催化活性,即最小的过电位可以产生较大的电流密度 [2] [10]。另一方面,电催化剂应具有出色的长期稳定性,这意味着电催化剂可以承受长周期的电解水而不致于催化活性大大降低 [11]。铂族金属基催化剂及其衍生物被认为是目前催化效率最好的HER催化剂,因为它们具有最佳的氢结合能(HBE)和氢吸附吉布斯自由能(ΔGH*),能够提供高交换电流密度(j0)和极小的Tafel斜率,并产生~100%的法拉第效率 [12]。而铱(Ir)基和钌(Ru)基化合物拥有非常突出的OER特性。然而,在可持续能源技术的框架内,高昂的价格限制了这些催化剂的商业化进程 [10] [11] [12] [13]。因此,设计和合成经济高效的过渡金属(TM)基大尺度水裂解催化剂一直是研究的重点和难点 [14]。在探索高效OER和HER电催化剂的基础上,人们做出了很大程度的努力,如OER的氧化物、硒化物、磷化物和氢氧化物,以及HER的碳化物、硫化物、氮化物和合金 [12] [13] [14] [15]。令人惋惜的是,大多数TM基催化剂本质上不如贵金属材料活跃,因为它们的导电性相对较低,动力学过程缓慢。这就促使人们通过在TM基电催化剂中施加各种工程策略,以期加快HER/OER过程的动力学 [14] [15] [16]。

在这篇综述中,我们总结了基于TM的电催化剂的工程策略,包括界面效应、缺陷效应、元素掺杂、晶面调控。以下各小节将详细介绍每种策略如何调整电催化剂,以提高催化性能。此外,我们也描述了催化剂的设计策略,包括增加每个活性位点的内在活性和增加活性位点数量,用于开发高活性催化剂。最后,还讨论了基于TM的电催化剂在未来发展可持续清洁氢能方面的挑战、前景和研究趋势。

2. 动力学调节工程

对于工业应用来说,电催化剂应具有良好的稳定性,这意味着它们可以在保证电催化活性的同时,承受长时间的电解水循环过程。在过去的几年里,大量的研究工作致力于开发和设计廉价和高效的功能水分解电催化剂,进展卓著。但TM基催化剂的催化效果始终无法与贵金属基催化剂比拟。因此,通过合理的工程策略设计高效且稳定的TM基水分解电催化剂已成为当务之急。

2.1. 界面工程

自支撑型电催化剂的关键界面的多尺度工程对于改善催化性能至关重要。自支撑型电催化剂的电荷转移过程可分为三个界面过程:1) 电催化剂内部,2) 基材/催化剂界面,3) 电解质/催化剂界面 [17]。通过控制这些界面可以有效提高自支撑型电催化剂性能,因此研究分析三个关键界面的多尺度工程问题尤为重要。本文我们将详细讨论异质结设计(内部电催化剂)、催化剂/基底界面和催化剂/电解质界面。

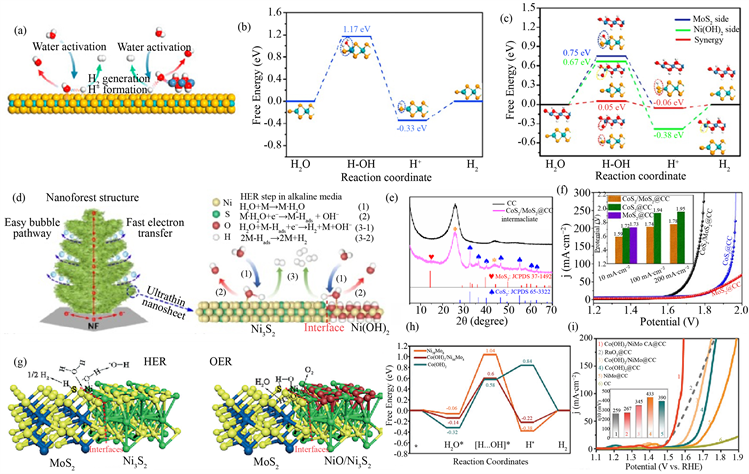

异质结的设计是界面工程的重要组成部分 [18]。异质结电催化剂由于其独特的物理化学特性,在电化学水分解中表现出优异的催化性能 [18] [19]。各种成分的组合将导致界面的协同效应、强烈的电子相互作用或在界面上的支持效应,从而使催化效率明显高于单独的成分。本文我们将深入讨论异质结电催化剂的结构优势,包括协同效应、电子相互作用和支持效应。协同效应为异质结电催化剂中的不同成分对催化反应有不同的影响,使异质结产生比单成分催化剂更好的催化活性 [19] [20]。不同的成分对不同的基元反应阶段显示出特殊的活性。因此,通过有效整合每种成分的多种优势,可以显著提高催化活性 [21]。例如,Ni(OH)2/MoS2电催化剂表现出很强的电催化活性,为了进一步阐明协同效应,研究者进行了基于密度泛函理论(DFT)的理论计算。图1(a)~(c)展示了基本HER的反应步骤,包括水解离生成吸附氢Hads和氢气生成。Ni(OH)2/MoS2界面处表现出有利的Hads结合自由能,接近于零,具有很强的反应性。因此,这种协同效应可以明显促进HER的动力学。Xu等人用超薄的Ni(OH)2/Ni3S2异质纳米片制备了一种新型的纳米森林电催化剂,对HER显示出良好的催化活性 [22]。实验研究表明(图1(d)),活性的提高主要是由于Ni(OH)2和Ni3S2之间的协同效应。异质结界面处电子的相互作用使得电子结构发生改变,电子从一个组分转移到另一个组分,穿过异质面,导致反应物/中间物的吸附和解吸的自由能大大改善,催化剂活性增强。例如,Zhou等人研究和设计了一种新型的异质结催化剂,对HER和OER具有良好的电催化性能 [23]。如图1(e)所示,从X射线衍射(XRD)图可知,在碳布基底上成功生成了六方相MoS2和低结晶度的立方相CoS2。异质结CoS2/MoS2@CC表现出优异的电催化性能,由CoS2/MoS2@CC组装的双电极电解质在10 mA∙cm−2时只需要1.59 V的电池电压(图1(f)) [24]。此外,异质结MoS2/Ni3S2具有丰富的界面(图1(g)),而X射线光电子能谱(XPS)结果验证了MoS2和Ni3S2之间强烈的电子相互作用。这一特性将有助于大幅提高HER和OER的性能。MoS2和Ni3S2/NiO之间建立的异质结界面可同时促进氢和含氧化物中间物的化学吸附,最终,电化学催化效率在整体水分解方面得到了明显提高。

基材和电催化剂之间的夹层也会影响电催化剂的一致性和催化效率。例如,直接生长在碳织物表面的CoS纳米片阵列比没有碳布的纳米颗粒表现出更好的HER活性 [25]。结果表明,基材的特性对催化性能有突出的影响。同时,通过调整自支撑电催化剂的界面间距,可以提高电催化的活性和稳定性,促进水分解效率。Gao等人报道了一种泡沫镍基电极,其在中性介质中对HER和OER都具有较高的电催化性能。实验结果表明,α-Ni(OH)2和金属镍之间没有明显的插层,证明活性成分和基底之间在原子水平上有强烈的关联性。这种特性赋予催化剂巨大的附着力,增强了电子传输能力和稳定性 [26]。

Figure 1. Interface engineering: (a) Schematic illustration of water activation; (b), (c) Free-energy diagram for HER on the MoS2, Ni(OH)2, and Ni(OH)2/MoS2 interface [21]; (d) Schematic illustration of the HER activity enhancing mechanism of the Ni(OH)2/Ni3S2 nanoforest in alkaline media [22]; (e) XRD patterns of pristine CC and CoS2/MoS2@CC intermediate; (f) Water splitting polarization curves of CoS2/MoS2@CC, CoS2@CC and MoS2@CC catalysts [23]; (g) Proposed mechanisms of water splitting on the MoS2/Ni3S2 interface [24]; (h) The corresponding free energy diagram for HER on the surface of Ni58Mo6 and Co(OH)2, and the interface of Co(OH)2/Ni44Mo4; (i) Polarization curves [38]

图1. 界面工程:(a) 水活化的示意图;(b),(c) MoS2、Ni(OH)2和Ni(OH)2/MoS2界面上的HER自由能图 [21];(d) 碱性介质中Ni(OH)2/Ni3S2纳米森林的HER活性增强机制示意图 [22];(e) 原始CC和CoS2/MoS2@CC中间体的XRD图案;(f) CoS2/MoS2@CC、CoS2@CC和MoS2@CC催化剂的极化曲线 [23];(g) MoS2/Ni3S2界面上的水分解机制 [24];(h) Ni58Mo6和Co(OH)2表面以及Co(OH)2/Ni44Mo4界面上的HER的相应自由能图;(i) 极化曲线 [38]

界面的微观形态(一维、二维或三维形态)的不同对催化剂的物理化学性质有着深远的影响,由此可以通过调控微观形态提高催化剂固有的催化活性 [27]。由于电子传输能力明显增强,大的比表面积促进了电解质的渗透和大量可用活性位点的形成,从而提高了催化活性 [28]。例如,一维纳米结构阵列能很好地保持其内在形态,不仅在内部和外部提供大的活性区域,而且还进一步增强了扩散速率 [29]。Li等人获得的NiCo2S4纳米棒表现出了极其显著的电化学性能 [30]。此外,NiMo氮化物纳米线阵列 [31]、菱形CoP2纳米线阵列 [32]、掺铜的CoP纳米棒阵列 [33]、氮化钴纳米线 [34] 和NiSe2纳米线阵列 [35] 都被证明是高度活跃的电催化剂 [36]。除了一般的纳米线阵列外,一维空心纳米结构阵列也得到了广泛的研究 [37]。

二维阵列纳米结构因其极高的理论比表面积,在界面工程控制方面也有很大的优势 [39]。一方面,二维纳米结构的横向尺寸和厚度对化学、物理和电子特性有决定性作用 [36] [37] [38] [39] [40]。另一方面,二维材料的大比表面积使它们有可能改善表面特性。因此,调整二维纳米结构的表面行为可以有效地获得用于电化学制氢的高活性电催化剂。例如,Ding等人制备了碳布上的CoP纳米片阵列(CoP/CC)表现出良好的稳定性 [39] [41],而其地毯状的形态有利于提高HER的性能 [41] [42]。Zhang等人报告了一种三维核壳结构 [38],由Co(OH)2空腔阵列包裹NiMo合金在柔性碳布基底上的三维核壳电催化剂(Co(OH)2/NiMo CA@CC)。如图1(h)所示,DFT计算表明NiMo与Co(OH)2的耦合可以更好地优化析氢反应中的水的解分和氢的吸附,加速OER的动力学。Co(OH)2/NiMo CA@CC的电流密度为10 mA∙cm−2,电池电压低至1.52 V (图1(i))。此外,在导电衬底上原位生长的纳米管阵列与衬底之间的紧密接触导致了较低的电荷转移电阻和减少了活性位点的阻塞。Wang等人报道了在碳布上自行形成空心无定形CoMoS4纳米管阵列(CoMoS4 NTA/CC) [43]。同样,Huang等人合成了超薄CoNi-MOF纳米片阵列(CoNi-MOFNA)作为高活性的OER电极 [44]。超薄的MOF纳米片可以完全覆盖三维CoNi合金泡沫。

2.2. 缺陷工程

缺陷的存在极大地改变了催化剂的电子结构和化学性质,导致新的物理化学性质或强烈的协同效应 [45]。从而提高电催化剂的催化性能 [45] [46]。缺陷可以被认为是材料中不均匀的成分,包括空位 [47]、掺杂物 [48]、边缘等 [46] [47] [48] [49]。因此,合理设计缺陷对于调整电催化剂的结构以提高催化活性至关重要。

空位是晶格缺陷的一种类型,晶格缺陷包括空位、间隙原子和替代原子缺陷 [50]。将空位(如O空位、S空位、N空位)引入电催化剂已被证明是一种有价值的缺陷工程,可以改善电催化行为。在最近几年,许多研究人员已经报道了产生阴离子空位(O、S、P、B等)的方法 [50] [51] [52]。

金属化合物中的空位缺陷,特别是氧空位缺陷,是比较容易获得的。根据早期的文献,到目前为止,除了热处理、还原和腐蚀等技术外,还有很多方法可以产生空位,例如,等离子体处理方法是一种快速而方便的获得空位缺陷的方法。等离子体处理技术可以在很短的时间内完成实验要求,而且成本低、效率高。Xu等人通过一步等离子体蚀刻技术合成具有氧空位的Co3O4基OER电催化剂(图2(a))。由于形成能量较低,在钴基催化剂中构建氧空位的方法也有多种。作为最常见的阴离子空位,氧空位可以调节半导体的能带间隙或在催化过程中在催化剂表面引起电子的重新分布,进一步改善催化性能。因此,空位点可以作为水吸附/解吸的活性点,减少能量壁垒并产生优化的反应动力学 [56]。例如,Li等人探索了一种全新的灵活的结构,能够有丰富的氧空位,为具有超快动力学的OER电催化剂提供了一个全新的途径 [54]。掺钴的四方钨青铜TTB结构Sr0.5Ba0.5Nb2−xCoxO6−δ样品的OER性能的明显改善可以归因于低价态的Co2+锚定在原本高价态的Nb5+位点上,从而产生了大量的O空位(图2(b)~(d))。Zhang等人研究了具有富氧空位的钠改性非晶/晶态RuO2 (a/c-RuO2) [55]。理论计算表明(图2(e)),Na掺杂和氧空位的引入削弱了OER中间物的吸附强度,从而降低了OER反应的势能。此外,a/c-RuO2表现出了显著的抗酸腐蚀和氧化性,具有非常高的催化稳定性(图2(f))。Liu等人通过水性等离子体剥离技术首次制备了具有多空位的超薄CoFe LDHs纳米片作为OER电催化剂 [57]。水性等离子体可以破坏基体金属层和层间阳离子之间的静电相互作用,导致基体的快速剥落。另一方面,等离子体的蚀刻作用可以有效地在剥落的超薄LDHs纳米片上同时产生多个空位,从而显著提高电催化活性。Zhang等人设计了一种通用的硒酸辅助刻蚀策略,以实现具有富硒空位的碳包覆三维金属硒化物M(Co0.85Se1−x, NiSe2−x, FeSe2−x)作为高性能无贵金属氧沉淀反应(OER)电催化剂 [58],研究结果揭示了丰富的硒空位在提高催化活性方面的重要作用。

2.3. 掺杂工程

异原子掺杂可以提高材料的导电性和诱导材料内部产生缺陷 [59],异原子掺杂会在电催化剂表面产生大量的催化活性位点 [60]。异原子掺杂发生在其他原子进入晶体的时候,可以分为两种类型:替代性异原子掺杂和间隙性异原子掺杂 [59] [60] [61]。非金属元素(如N、O、P、S、B)和金属元素(如Cr、Fe、Cu、Mn、Co)已被研究认为是有效的掺杂物 [62]。异原子掺杂不仅促进了电子转移,而且还调节了吸附/解吸行为 [62] [63],产生大量的活性点,使电催化性能得到明显的改善。其中,金属原子掺杂是最常见的一种。Sun等人在石墨板上设计合成了一种新型的超亲水Co4N-CeO2混合纳米片阵列(Co4N-CeO2/GP) [64]。

Figure 2. Defect engineering: (a) Illustration of the preparation of the Ar-plasma-engraved Co3O4 with oxygen vacancies and high surface area [53]; (b) Schematic illustration of the replacement of Nb5+ by Co in the tetragonal tungsten bronze TTB structure; (c) Spin configuration evolution from high-spin Co2+ to low-spin Co2+ in the octahedron due to further crystal field splitting caused by the generation of Ovac; (d) A possible oxygen intercalation mechanism, with the dashed box representing Ovac [54]; (e) Calculated free-energy diagram for OER on RuO2, Na-RuO2, RuO2-VO, and Na-RuO2-VO surfaces, rate-determining step is indicated by vertical dashed line for Na-RuO2-VO; (f) Polarization curves before and after CV cycling for a/c-RuO2 and commercial RuO2 in 0.1 M HClO4 [55]

图2. 缺陷工程:(a) 具有氧空位和高表面积的氩等离子体刻蚀的Co3O4的制备说明 [53];(b) 四方钨青铜TTB结构中用Co替代Nb5+的示意图;(c) 由于Ovac的产生导致进一步的晶场分裂,八面体中的自旋构型从高自旋Co2+演变为低自旋Co2+;(d) 潜在的氧插层机制,虚线框代表Ovac [54];(e) 在RuO2、Na-RuO2、RuO2-VO和Na-RuO2-VO表面进行OER的计算自由能图;Na-RuO2-VO的速率决定步骤由垂直虚线表示;(f) a/c-RuO2和商用RuO2在0.1M HClO4中的CV循环前后的极化曲线 [55]

实验结果表明(图3(a)),这种超亲水结构促进了H2O的解离和氢的吸附,降低了OER中间反应的能垒,提高了成分的稳定性,从而在诱导增强OER活性的同时,显著提高HER性能(图3(b))。除了金属掺杂之外,非金属的引入也会影响电催化的活性。常见的非金属杂原子主要包括磷、硫、硼、氮和氧原子。随着非金属杂原子的存在,电催化剂的物理化学特性和电子结构将会发生变化。例如,Ouyang等人制备了磷掺杂的二硫化钴纳米片作为高效的HER电催化剂 [51],这些磷掺杂的钴基硫化物显示了出色的HER性能。同样地,Zhang等人通过简单的一步水热合成方法制备了掺磷的CoS2 [65],钴的价态与之前报道的P掺杂的CoS2 (P-CoS2)接近(图3(c))。此外,双掺杂电催化剂(如金属和非金属,金属和金属,非金属和非金属)也有报道。Dong等人报道了利用阳极氧化/电沉积/氮化过程在铁箔上原位合成含有Fe3N的CoNi纳米管(CoNiFe3N),以增强OER催化作用 [66]。DFT计算进一步表明(图3(d),图3(e)),CoNi-FeOOH中的Ni位点可以调节OER中间体的吸附,并提供比Fe和Co位点更低的过电位,使其成为具有最佳OER活性位点。Dong等人在三维镍泡沫上制备了Fe掺杂的CoF2纳米线阵列 [67]。实验结果表明,催化活性位点的增加和电荷转移速率的加快使自支撑的Fe掺杂的CoF2电极在碱性电解质中表现出优异的OER性能。Wang等人设计了一种杂原子掺杂的多相磷化镍/硫化镍(Mo-NiPx/NiSy)纳米线电催化剂,用于促进碱性溶液中的全水分解 [68]。

Figure 3. Doping engineering: (a) DFT calculated reaction energy diagram of water dissociation for Co4N(111) and Co4N(111)-CeO2(111); (b) Polarization curves of Co4N-CeO2/GP, Co4N/GP, Co(OH)2-CeO2/GP, Co(OH)2/GP, CeO2/GP, and the benchmark RuO2/GP in 1 M KOH [64]; (c) Free-energy diagram for H* adsorption at the Co site on the (001) surface of CoS2, and at the Co site, P site, and Co site after H* at P site on the (001) surface of P doped CoS2 and their optimal atomic structures [65]; (d) OER pathway on CoNi-FeOOH catalyst; (e) Calculated free energy diagram for OER on the metal active sites (M) of FeOOH ([Fe]_M), Co-FeOOH ([Co-Fe]_M), Ni-FeOOH ([Ni-Fe]_M), and CoNi-FeOOH ([CoNi-Fe]_M) catalysts [66]

图3. 掺杂工程:(a) DFT计算的Co4N(111)和Co4N(111)-CeO2(111)的水解反应能图;(b) Co4N-CeO2/GP、Co4N/GP、Co(OH)2-CeO2/GP、Co(OH)2/GP、CeO2/GP和基准RuO2/GP在1 M KOH中的极化曲线 [64];(c) H*在CoS2的(001)表面的Co位点,以及在P掺杂的CoS2的(001)表面的Co位点、P位点和H*后的Co位点的自由能图及其最佳原子结构 [65];(d) CoNi-FeOOH催化剂上的OER途径;(e) FeOOH ([Fe]_M)、Co-FeOOH ([Co-Fe]_M)、Ni-FeOOH ([Ni-Fe]_M)和CoNi-FeOOH ([CoNi-Fe]_M)催化剂的金属活性部位M上OER的计算自由能图 [66]

2.4. 晶面工程

不同的晶体表面具有不同的几何和电子结构,因此表现出不同的物理化学性质,这是改善表面电荷分裂的有效策略。晶体的表面特性,如表面切面和表面相,可以明显影响活性位点的数量和反应性 [69]。例如,Song等人提出了一种歧化分解策略(图4(a)),通过直接生成Ti和C原子来合成单晶(100)切面的TiC粉末 [70]。实验结果显示,TiC(100)晶面在析氢反应方面具有良好的电化学性能。此外,具有(110)面的NiCo2O4比具有(111)或(100)面的NiCo2O4表现出更高的HER/OER电催化活性(图4(b)) [71]。具有(002)晶体面的ZnO光电阳极比具有(002)或(100)晶体面的ZnO光电阳极显示出更好的水分裂活性 [72]。

通过一定手段暴露特定晶面,电催化剂的电催化性能可以得到明显的改善。因此,选择性地暴露高活性晶体表面可以极大地提高其电催化活性。Feng等人使用泡沫镍作为导电基体和镍源,成功地制造了一组具有不同暴露晶面的Ni3S2 [73]。所设计的电催化剂的反应分别由(2̅10)、(2̅10)/(001)和(001)主导。通过DFT计算进一步了解表面结构性能,如(图4(c))所示,在Ni3S2的(2̅10)平面和表面较粗糙的(001)平面中可以观察到明显的原子阶梯。计算结果表明,Ni-Ni键和Ni位点是(001)面的活性位点,而(2̅10)面比(001)面显示了更多的活性Ni和Ni-Ni位点。此外,(2̅10)平面上存在三种类型的S-活性位点,它们比(001)平面上的位点更活跃,因此,(2̅10)平面比(001)板表现出更好的HER活性。

Figure 4. Crystal face engineering: (a) Schematic diagram for the synthesis of cubic shaped TiC powders from the TiCl2-CH4 system [70]; (b) The surface atomic configurations of NiCo2O4 in (100), (110) and (111) crystal planes, and the HER free energy change diagram of NiCo2O4 (100), (110) and (111) crystal plane [71]; (c) Free-energy diagram for hydrogen (H*) adsorption over (2̅10) and (001) surfaces [73]; (d) Standard free energy diagram for the OER on different electrodes, inset at bottom right corner is the atomic structure of Ni3Nb embedded in NiFe-OOH [74]

图4. 晶面工程:(a) 从TiCl2-CH4系统合成立方体形状的TiC粉末的示意图 [70];(b) NiCo2O4在(100)、(110)和(111)晶面的表面原子构型,以及NiCo2O4 (100)、(110)和(111)晶面的HER自由能变化图 [71];(c) 氢气(H*)在(2̅10)和(001)表面吸附的自由能图 [73];(d) 不同电极上OER的标准自由能图,右下角的插图是嵌入NiFe-OOH中的Ni3Nb的原子结构 [74]

此外,Deng等人还制备了具有高度暴露的(2̅10)高指数面的新型核支架结构TiO2@Ni2S3 [75],(003)面暴露的Ni3S2 [76],(1̅20)高指数面的NiCx纳米片 [77],和面工程Ni-Co氢氧化物纳米阵列 [78],并对HER和OER都显示出明显的电催化活性。Chang等人开发了一种具有优良OER性能的高活性和导电的壳基细胞(shcellular)电极(图4(d)),DFT计算表明,纳米晶体Ni3Nb可以同时提高催化剂膜的导电性和活性 [74]。晶体切片的控制可以阐明对表面特性和电催化活性之间的关联性的深入理解,从而指导高性能电催化剂的设计。Cai等人采用了一种简便的各向异性表面改性和刻蚀策略,他们制备了中空结构的ZIF-67纳米框架 [79]。Pt含量仅为5.9 wt.%的Pt Co/C催化剂在酸性溶液中的HER表现出很高的催化活性和稳定性。

3. 总结与展望

过渡金属基催化剂由于其各种优势,在电化学水分解中得到了广泛的关注和应用。尽管在电催化剂设计工程方面已经取得了很大的进展,但在以提高过渡金属基材料作为新的高效和强大的电催化剂的动力学中,仍有一些关键的挑战没有得到解决。

1) 每个电催化剂设计工程对催化活性的具体调节作用和精确影响。

2) 反应过程中,催化剂的界面成分和相态的复杂性使得监测表面和内在活性部位的实时演化行为变得极为困难。

3) 无论是电催化活性还是电流密度,目前基于TM的催化剂都远远不能满足工业化的需要。

未来,TM基材料的发展应主要集中在以下四个方向。

1) 探索高效TM基材料催化的精确调控策略,阐明电催化性能与材料结构之间的“结构–活性”关系。

2) 借助于机器学习、理论计算和三维有限元模拟,实现高效TM基电催化剂的顶层设计,模拟再现界面反应的动态过程。

3) 开发新的原位表征技术,揭示电催化剂表面的实时结构演化行为,对识别内在活性位点和澄清催化机制起着关键作用。

4) 从系统工程的角度来看,开发多功能耦合的集成电化学装置在TM基材料的水分解产业化中起着重要作用。

展望未来,毫无疑问,在这一充满希望的领域继续研究和开发将有效推进氢能的产业化,从而为早日实现碳中和蓝图做出贡献。

基金项目

江苏省自然科学基金(BK20210847),江苏省高校面上项目(21KJB430042,22KJB430039)。

文章引用

许国栋,冯明月,王诗雨,程 煜,张莉芳. 过渡金属基电催化剂在全解水反应中的动力学调控策略

Kinetic Regulation Strategies of Transition-Metal-Based Electrocatalysts in Water Splitting Reaction[J]. 纳米技术, 2022, 12(04): 371-383. https://doi.org/10.12677/NAT.2022.124037

参考文献

- 1. Zhang, L., Jang, H., Liu, H., Kim, M.G., Yang, D., Liu, S., Liu, X. and Cho, J. (2021) Sodium-Decorated Amorphous/Crystalline RuO2 with Rich Oxygen Vacancies: A Robust pH-Universal Oxygen Evolution Electrocatalyst. Angewandte Chemie International Edition, 60, 18821-18829. https://doi.org/10.1002/anie.202106631

- 2. Zhao, H. and Yuan, Z.Y. (2021) Surface/Interface Engineering of High-Efficiency Noble Metal-Free Electrocatalysts for Energy-Related Electrochemical Reactions. Journal of Energy Chemistry, 54, 89-104. https://doi.org/10.1016/j.jechem.2020.05.048

- 3. Liu, R., Wang, Y., Liu, D., Zou, Y. and Wang, S. (2017) Wa-ter-Plasma-Enabled Exfoliation of Ultrathin Layered Double Hydroxide Nanosheets with Multivacancies for Water Oxi-dation. Advanced Materials, 29, Article ID: 1701546. https://doi.org/10.1002/adma.201701546

- 4. Zhang, L., Lu, C., Ye, F., Pang, R., Liu, Y., Wu, Z., Shao, Z., Sun, Z. and Hu, L. (2021) Selenic acid Etching Assisted Vacancy Engineering for Designing Highly Active Electrocatalysts to-ward the Oxygen Evolution Reaction. Advanced Materials, 33, e2007523. https://doi.org/10.1002/adma.202007523

- 5. Wang, J., Ge, X., Liu, Z., Thia, L., Yan, Y., Xiao, W. and Wang, X. (2017) Heterogeneous Electrocatalyst with Molecular Cobalt Ions Serving as the Center of Active Sites. Journal of the American Chemical Society, 139, 1878-1884. https://doi.org/10.1021/jacs.6b10307

- 6. Liu, Y., Cheng, H., Lyu, M., Fan, S., Liu, Q., Zhang, W., Zhi, Y., Wang, C., Xiao, C., Wei, S., Ye, B. and Xie, Y. (2014) Low Overpotential in Vacancy-Rich Ultrathin CoSe2 Nanosheets for Water Oxidation. Journal of the American Chemical Society, 136, 15670-15675. https://doi.org/10.1021/ja5085157

- 7. Cobo, S., Heidkamp, J., Jacques, P.A., Fize, J., Fourmond, V., Guetaz, L., Jousselme, B., Ivanova, V., Dau, H., Palacin, S., Fontecave, M. and Artero, V. (2012) A Janus Cobalt-Based Catalytic Material for Electro-Splitting of Water. Nature Materials, 11, 802-807. https://doi.org/10.1038/nmat3385

- 8. Wang, Y., Xie, C., Liu, D., Huang, X., Huo, J. and Wang, S. (2016) Nano-particle-Stacked Porous Nickel-Iron Nitride Nanosheet: A Highly Efficient Bifunctional Electrocatalyst for Overall Water Splitting. ACS Applied Materials & Interfaces, 8, 18652-18657. https://doi.org/10.1021/acsami.6b05811

- 9. Zhang, R., Tang, C., Kong, R., Du, G., Asiri, A.M., Chen, L. and Sun, X. (2017) Al-Doped CoP Nanoarray: A Durable Water-Splitting Electrocatalyst with Superhigh Activity. Nanoscale, 9, 4793-4800. https://doi.org/10.1039/C7NR00740J

- 10. Sun, H., Tian, C., Fan, G., Qi, J., Liu, Z., Yan, Z., Cheng, F., Chen, J., Li, C.P. and Du, M. (2020) Boosting Activity on Co4N Porous Nanosheet by Coupling CeO2 for Efficient Electrochemi-cal Overall Water Splitting at High Current Densities. Advanced Functional Materials, 30, Article ID: 1910596. https://doi.org/10.1002/adfm.201910596

- 11. Zhang, J., Liu, Y., Xia, B., Sun, C., Liu, Y., Liu, P. and Gao, D. (2018) Facile One-Step Synthesis of Phosphorus-Doped CoS2 as Efficient Electrocatalyst for Hydrogen Evolution Reac-tion. Electrochimica Acta, 259, 955-961. https://doi.org/10.1016/j.electacta.2017.11.043

- 12. Dong, J., Lu, Y., Tian, X., Zhang, F.Q., Chen, S., Yan, W., He, H.L., Wang, Y., Zhang, Y.B., Qin, Y., Sui, M., Zhang, X.M. and Fan, X. (2020) Genuine Active Species Generated from Fe3N Nanotube by Synergistic CoNi Doping for Boosted Oxygen Evolution Catalysis. Small, 16, e2003824. https://doi.org/10.1002/smll.202003824

- 13. Dong, Q., Su, T., Ge, W., Ren, Y., Liu, Y., Wang, W., Wang, Q. and Dong, X. (2020) Atomic Doping and Anion Reconstructed CoF2 Electrocatalyst for Oxygen Evolution Reaction. Ad-vanced Materials Interfaces, 7, Article ID: 1901939. https://doi.org/10.1002/admi.201901939

- 14. Wang, J., Zhang, M., Yang, G., Song, W., Zhong, W., Wang, X., Wang, M., Sun, T. and Tang, Y. (2021) Heterogeneous Bimetallic Mo-NiPx/NiSy as a Highly Efficient Electrocatalyst for Robust Overall Water Splitting. Advanced Functional Materials, 31, Article ID: 2101532. https://doi.org/10.1002/adfm.202101532

- 15. Bai, S., Jiang,W., Li, Z. and Xiong, Y. (2015) Surface and Interface Engineering in Photocatalysis. ChemNanoMat, 1, 223-239. https://doi.org/10.1002/cnma.201500069

- 16. Song, M., Chen, D., Yang, Y., Xiang, M., Zhu, Q., Zhao, H., Ward, L. and Chen, X.B. (2020) Crystal Facet Engineering of Sin-gle-Crystalline TiC Nanocubes for Improved Hydrogen Evolution Reaction. Advanced Functional Materials, 31, Article ID: 2008028. https://doi.org/10.1002/adfm.202008028

- 17. Fang, L., Jiang, Z., Xu, H., Liu, L., Guan, Y., Gu, X. and Wang, Y. (2018) Crystal-Plane Engineering of NiCo2O4 Electrocatalysts towards Efficient Overall Water Splitting. Journal of Catalysis, 357, 238-246. https://doi.org/10.1016/j.jcat.2017.11.017

- 18. Pawar, A.U., Kim, C.W., Kang, M.J. and Kang, Y.S. (2016) Crystal Facet Engineering of ZnO Photoanode for the Higher Water Splitting Efficiency with Proton Transferable Nafion Film. Nano Energy, 20, 156-167. https://doi.org/10.1016/j.nanoen.2015.11.035

- 19. 王钟, 刘家岐, 刘琛, 袁双, 王强. 过渡金属磷化物用于电解水析氢反应的研究进展[J]. 中国有色金属学报, 2021, 31(11): 3344-3361.

- 20. Feng, L.L., Yu, G., Wu, Y., Li, G.D., Li, H., Sun, Y., Asefa, T., Chen, W. and Zou, X. (2015) High-Index Faceted Ni3S2 Nanosheet Arrays as Highly Active and Ultrastable Electrocata-lysts for Water Splitting. Journal of the American Chemical Society, 137, 14023-14026. https://doi.org/10.1021/jacs.5b08186

- 21. Chang, S., Zhang, Y., Zhang, B., Cao, X., Zhang, L., Huang, X., Lu, W., Ong, C.Y.A., Yuan, S., Li, C., Huang, Y., Zeng, K., Li, L., Yan, W. and Ding, J. (2021) Conductivity Modulation of 3D-Printed Shellular Electrodes through Embedding Nanocrystalline Intermetallics into Amorphous Matrix for Ultra-high-Current Oxygen Evolution. Advanced Energy Materials, 11, Article ID: 2100968. https://doi.org/10.1002/aenm.202100968

- 22. 陈香平, 苏丽荣, 吴燕霞, 王庆涛, 任书芳. 过渡金属磷化物用于电解水析氢反应的研究进展[J]. 功能材料, 2021, 52(6): 6059-6068.

- 23. Deng, S., Zhang, K., Xie, D., Zhang, Y., Zhang, Y., Wang, Y., Wu, J., Wang, X., Fan, H.J., Xia, X. and Tu, J. (2019) High-Index-Faceted Ni3S2 Branch Arrays as Bifunctional Electrocata-lysts for Efficient Water Splitting. Nano-Micro Letters, 11, Article No. 12. https://doi.org/10.1007/s40820-019-0242-8

- 24. Dong, J., Zhang, F.-Q., Yang, Y., Zhang, Y.-B., He, H., Huang, X., Fan, X. and Zhang, X.-M. (2019) (003)-Facet-Exposed Ni3S2 Nanoporous Thin Films on Nickel Foil for Efficient Water Splitting. Applied Catalysis B: Environmental, 243, 693-702. https://doi.org/10.1016/j.apcatb.2018.11.003

- 25. 李媛媛. N掺杂MoxC/CoP复合材料的制备及电解水析氢性能研究[D]: [硕士学位论文]. 郑州: 郑州大学, 2021.

- 26. 史艳梅, 张兵. 过渡金属磷化物作为高效电解水析氢及加氢催化剂[J]. 科学观察, 2020, 15(6): 59-61.

- 27. Yang, H., Luo, S., Li, X., Li, S., Jin, J. and Ma, J. (2016) Con-trollable Orientation-Dependent Crystal Growth of High-Index Faceted Dendritic NiC0.2 Nanosheets as High-Performance Bifunctional Electrocatalysts for Overall Water Splitting. Journal of Materials Chemistry A, 4, 18499-18508. https://doi.org/10.1039/C6TA07038H

- 28. Lu, Y., Zhang, H., Du, Y., Han, C., Nie, Z., Sun, Z., Rui, K., Zhu, J. and Huang, W. (2020) Structure Design of Ni-Co Hydroxide Nanoarrays with Facet Engineering on Carbon Chainlike Nanofibers for High-Efficiency Oxygen Evolution. ACS Applied Energy Materials, 3, 6240-6248. https://doi.org/10.1021/acsaem.0c00348

- 29. 杨雪莹. 过渡金属Ni、Co、Mo化合物电极的制备及其电解水析氢性能研究[D]: [硕士学位论文]. 哈尔滨: 哈尔滨工程大学, 2018.

- 30. Hou, J., Wu, Y., Zhang, B., Cao, S., Li, Z. and Sun, L. (2019) Rational Design of Nanoarray Architectures for Electrocatalytic Water Splitting. Ad-vanced Functional Materials, 29, Article ID: 1808367. https://doi.org/10.1002/adfm.201808367

- 31. Gao, Q., Zhang, W., Shi, Z., Yang, L. and Tang, Y. (2019) Structural Design and Electronic Modulation of Transition-Metal-Carbide Electrocatalysts toward Efficient Hydrogen Evolution. Advanced Materials, 31, Article ID: 1802880. https://doi.org/10.1002/adma.201802880

- 32. Morales-Guio, C.G., Stern, L.A. and Hu, X. (2014) Nanostructured Hydrotreating Catalysts for Electrochemical Hydrogen Evolution. Chemical Society Reviews, 43, 6555-6569. https://doi.org/10.1039/C3CS60468C

- 33. De Levie, R. (1999) The Electrolysis of Water. Journal of Electroana-lytical Chemistry, 476, 92-93. https://doi.org/10.1016/S0022-0728(99)00365-4

- 34. Chu, S. and Majumdar, A. (2012) Opportunities and Chal-lenges for a Sustainable Energy Future. Nature, 488, 294-303. https://doi.org/10.1038/nature11475

- 35. Wu, Z.P. and Zhong, C.J. (2021) Pd-Based Electrocatalysts for Oxygen Reduction and Ethanol Oxidation Reactions: Some Recent Insights into Structures and Mechanisms. Journal of Electro-chemistry, 27, 144-156.

- 36. Nie, Y., Li, L. and Wei, Z. (2015) Recent Advancements in Pt and Pt-Free Catalysts for Oxygen Reduction Reaction. Chemical Society Reviews, 44, 2168-2201. https://doi.org/10.1039/C4CS00484A

- 37. Qin, X., Li, Z.Q., Pan, J.B., Li, J., Wang, K. and Xia, X.H. (2021) Electrochemiluminescence Imaging Hydrogen Evolution Reaction on Single Platinum Nanoparticles Using a Bipolar Nanoelectrode Array. Journal of Electrochemistry, 27, 157-167.

- 38. Vij, V., Sultan, S., Harzandi, A.M., Meena, A., Tiwari, J.N., Lee, W.G., Yoon, T. and Kim, K.S. (2017) Nickel-Based Electrocatalysts for Energy-Related Applications: Oxygen Reduction, Oxygen Evolution, and Hydrogen Evolution Reactions. ACS Catalysis, 7, 7196-7225. https://doi.org/10.1021/acscatal.7b01800

- 39. Zhuang, Z.H. and Chen, W. (2021) Application of Atomically Pre-cise Metal Nanoclusters in Electrocatalysis. Journal of Electrochemistry, 27, 125-143.

- 40. Yuan, C.Z., Hui, K.S., Yin, H., Zhu, S., Zhang, J., Wu, X.L., Hong, X., Zhou, W., Fan, X., Bin, F., Chen, F. and Hui, K.N. (2021) Regulating In-trinsic Electronic Structures of Transition-Metal-Based Catalysts and the Potential Applications for Electrocatalytic Water Splitting. ACS Materials Letters, 3, 752-780. https://doi.org/10.1021/acsmaterialslett.0c00549

- 41. Lee, M.Y., Ha, H., Cho, K.H., Seo, H., Park, S., Lee, Y.H., Kwon, S.J., Lee, T.W. and Nam, K.T. (2020) Importance of Interfacial Band Structure between the Substrate and Mn3O4 Nanocatalysts during Electrochemical Water Oxidation. ACS Catalysis, 10, 1237-1245. https://doi.org/10.1021/acscatal.9b03831

- 42. Wang, H., Fu, W., Yang, X., Huang, Z., Li, J., Zhang, H. and Wang, Y. (2020) Recent Advancements in Heterostructured Interface Engineering for Hydrogen Evolution Reaction Electroca-talysis. Journal of Materials Chemistry A, 8, 6926-6956. https://doi.org/10.1039/C9TA11646J

- 43. Zhao, G., Rui, K., Dou, S.X. and Sun, W. (2020) Boosting Electrochemical Water Oxidation: The Merits of Heterostructured Electrocat-alysts. Journal of Materials Chemistry A, 8, 6393-6405. https://doi.org/10.1039/D0TA00708K

- 44. Zhang, W.Q. and Yu, B. (2020) Development Status and Prospects of Hydrogen Production by High Temperature Solid Oxide Elec-trolysis. Journal of Electrochemistry, 26, 212-229.

- 45. Zhang, B., Liu, J., Wang, J., Ruan, Y., Ji, X., Xu, K., Chen, C., Wan, H., Miao, L. and Jiang, J. (2017) Interface Engineering: The Ni(OH)2/MoS2 Heterostructure for Highly Efficient Alkaline Hydrogen Evolution. Nano Energy, 37, 74-80. https://doi.org/10.1016/j.nanoen.2017.05.011

- 46. Xu, Q., Jiang, H., Zhang, H., Hu, Y. and Li, C. (2019) Hetero-geneous Interface Engineered Atomic Configuration on Ultrathin Ni(OH)2/Ni3S2 Nanoforests for Efficient Water Split-ting. Applied Catalysis B: Environmental, 242, 60-66. https://doi.org/10.1016/j.apcatb.2018.09.064

- 47. Zhou, G., Wu, X., Zhao, M., Pang, H., Xu, L., Yang, J. and Tang, Y. (2021) Interfacial Engineering-Triggered Bifunctionality of CoS2/MoS2 Nanocubes/Nanosheet Arrays for High-Efficiency Overall Water Splitting. ChemSusChem, 14, 699-708. https://doi.org/10.1002/cssc.202002338

- 48. Zhang, Z., Ji, X., Shi, J., Zhou, X., Zhang, S., Hou, Y., Qi, Y., Fang, Q., Ji, Q., Zhang, Y., Hong, M., Yang, P., Liu, X., Zhang, Q., Liao, L., Jin, C., Liu, Z. and Zhang, Y. (2017) Direct Chemical Vapor Deposition Growth and Band-Gap Characterization of MoS2/h-BN van der Waals Heterostructures on Au Foils. ACS Nano, 11, 4328-4336. https://doi.org/10.1021/acsnano.7b01537

- 49. Li, N., Liu, X., Li, G.-D., Wu, Y., Gao, R. and Zou, X. (2017) Ver-tically Grown CoS Nanosheets on Carbon Cloth as Efficient Hydrogen Evolution Electrocatalysts. The International Journal of Hydrogen Energy, 42, 9914-9921. https://doi.org/10.1016/j.ijhydene.2017.01.191

- 50. Gao, X., Chen, Y., Sun, T., Huang, J., Zhang, W., Wang, Q. and Cao, R. (2020) Karst Landform-Featured Monolithic Electrode for Water Electrolysis in Neutral Media. Energy & Environmental Science, 13, 174-182. https://doi.org/10.1039/C9EE02380A

- 51. Li, J. and Zheng, G. (2017) One-Dimensional Earth-Abundant Nano-materials for Water-Splitting Electrocatalysts. Advanced Science (Weinh), 4, Article ID: 1600380. https://doi.org/10.1002/advs.201600380

- 52. Li, X. and Wang, J. (2019) One-Dimensional and Two-Dimensional Synergized Nanostructures for High-Performing Energy Storage and Conversion. InfoMat, 2, 3-32. https://doi.org/10.1002/inf2.12040

- 53. Lu, Q., Hutchings, G.S., Yu, W., Zhou, Y., Forest, R.V., Tao, R., Rosen, J., Yonemoto, B.T., Cao, Z., Zheng, H., Xiao, J.Q., Jiao, F. and Chen, J.G. (2015) Highly Porous Non-Precious Bime-tallic Electrocatalysts for Efficient Hydrogen Evolution. Nature Communications, 6, Article No. 6567. https://doi.org/10.1038/ncomms7567

- 54. Li, X.X., Wang, X.T., Xiao, K., Ouyang, T., Li, N. and Liu, Z.Q. (2018) In Situ Formation of Consubstantial NiCo2S4 Nanorod Arrays toward Self-Standing Electrode for High Activity Super-capacitors and Overall Water Splitting. Journal of Power Sources, 402, 116-123. https://doi.org/10.1016/j.jpowsour.2018.09.021

- 55. Wang, Y., Sun, Y., Yan, F., Zhu, C., Gao, P., Zhang, X. and Chen, Y. (2018) Self-Supported NiMo-Based Nanowire Arrays as Bifunctional Electrocatalysts for Full Water Splitting. Journal of Materials Chemistry A, 6, 8479-8487. https://doi.org/10.1039/C8TA00517F

- 56. Zhou, Y., Yang, Y., Wang, R., Wang, X., Zhang, X., Qiang, L., Wang, W., Wang, Q. and Hu, Z. (2018) Rhombic Porous CoP2 Nanowire Arrays Synthesized by Alkaline Etching as Highly Active Hydrogen-Evolution-Reaction Electrocatalysts. Journal of Materials Chemistry A, 6, 19038-19046. https://doi.org/10.1039/C8TA06462H

- 57. Wen, L., Sun, Y., Zhang, C., Yu, J., Li, X., Lyu, X., Cai, W. and Li, Y. (2018) Cu-Doped CoP Nanorod Arrays: Efficient and Durable Hydrogen Evolution Reaction Electrocatalysts at All pH Values. ACS Applied Energy Materials, 1, 3835-3842. https://doi.org/10.1021/acsaem.8b00609

- 58. Xue, Z., Kang, J., Guo, D., Zhu, C., Li, C., Zhang, X. and Chen, Y. (2018) Self-Supported Cobalt Nitride Porous Nanowire Arrays as Bifunctional Electrocatalyst for Overall Water Splitting. Electrochimica Acta, 273, 229-238. https://doi.org/10.1016/j.electacta.2018.04.056

- 59. Guo, Y., Guo, D., Ye, F., Wang, K., Shi, Z., Chen, X. and Zhao, C. (2018) Self-Supported NiSe2 Nanowire Arrays on Carbon Fiber Paper as Efficient and Stable Electrode for Hydrogen Evolution Reaction. ACS Sustainable Chemistry & Engineering, 6, 11884-11891. https://doi.org/10.1021/acssuschemeng.8b02164

- 60. Qi, J., Lai, X., Wang, J., Tang, H., Ren, H., Yang, Y., Jin, Q., Zhang, L., Yu, R., Ma, G., Su, Z., Zhao, H. and Wang, D. (2015) Multi-Shelled Hollow Micro-/Nanostructures. Chemi-cal Society Reviews, 44, 6749-6773. https://doi.org/10.1039/C5CS00344J

- 61. Lu, H.S., He, X.B., Yin, F.X. and Li, G.R. (2020) Preparations of Nick-el-Iron Hydroxide/Sulfide and Their Electrocatalytic Performances for Overall Water Splitting. Journal of Electrochemis-try, 26, 136-147.

- 62. Zhang, Q., Xiao, W., Guo, W.H., Yang, Y.X., Lei, J.L., Luo, H.Q. and Li, N.B. (2021) Macroporous Array Induced Multiscale Modulation at the Surface/Interface of Co(OH)2/NiMo Self-Supporting Electrode for Effective Overall Water Splitting. Advanced Functional Materials, 31, Article ID: 2102117. https://doi.org/10.1002/adfm.202102117

- 63. Ding, Y.L., Kopold, P., Hahn, K., Van Aken, P.A., Maier, J. and Yu, Y. (2016) Facile Solid-State Growth of 3D Well-Interconnected Nitrogen-Rich Carbon Nanotube-Graphene Hybrid Ar-chitectures for Lithium-Sulfur Batteries. Advanced Functional Materials, 26, 1112-1119. https://doi.org/10.1002/adfm.201504294

- 64. Yang, X., Lu, A.Y., Zhu, Y., Hedhili, M.N., Min, S., Huang, K.W., Han, Y. and Li, L.J. (2015) CoP Nanosheet Assembly Grown on Carbon Cloth: A Highly Efficient Electrocatalyst for Hydrogen Generation. Nano Energy, 15, 634-641. https://doi.org/10.1016/j.nanoen.2015.05.026

- 65. Zhao, S., Wang, Y., Dong, J., He, C.T., Yin, H., An, P., Zhao, K., Zhang, X., Gao, C., Zhang, L., Lv, J., Wang, J., Zhang, J., Khattak, A.M., Khan, N.A., Wei, Z., Zhang, J., Liu, S., Zhao, H. and Tang, Z. (2016) Ultrathin Metal-Organic Framework Nanosheets for Electrocatalytic Oxygen Evolution. Nature Energy, 1, Article No. 16184. https://doi.org/10.1038/nenergy.2016.184

- 66. Li, F.L., Wang, P., Huang, X., Young, D.J., Wang, H.F., Braun-stein, P. and Lang, J.P. (2019) Large-Scale, Bottom-Up Synthesis of Binary Metal-Organic Framework Nanosheets for Efficient Water Oxidation. Angewandte Chemie International Edition, 58, 7051-7056. https://doi.org/10.1002/anie.201902588

- 67. Wang, W., Ren, X., Hao, S., Liu, Z., Xie, F., Yao, Y., Asiri, A.M., Chen, L. and Sun, X. (2017) Self-Templating Construction of Hollow Amorphous CoMoS4 Nanotube Array towards Efficient Hydrogen Evolution Electrocatalysis at Neutral Ph. Chemistry—A European Journal, 23, 12718-12723. https://doi.org/10.1002/chem.201702923

- 68. Huang, L., Gao, G., Zhang, H., Chen, J., Fang, Y. and Dong, S. (2020) Self-Dissociation-Assembly of Ultrathin Metal-Organic Framework Nanosheet Arrays for Efficient Oxygen Evolution. Nano Energy, 68, Article ID: 104296. https://doi.org/10.1016/j.nanoen.2019.104296

- 69. Zhu, Y., Liu, X., Jin, S., Chen, H., Lee, W., Liu, M. and Chen, Y. (2019) Anionic Defect Engineering of Transition Metal Oxides for Oxygen Reduction and Evolution Reactions. Journal of Materials Chemistry A, 7, 5875-5897. https://doi.org/10.1039/C8TA12477A

- 70. Zhang, H. and Lv, R. (2018) Defect Engineering of Two-Dimensional Materials for Efficient Electrocatalysis. Journal of Materiomics, 4, 95-107. https://doi.org/10.1016/j.jmat.2018.02.006

- 71. Wang, Y., Han, P., Lv, X., Zhang, L. and Zheng, G. (2018) Defect and Interface Engineering for Aqueous Electrocatalytic CO2 Reduction. Joule, 2, 2551-2582. https://doi.org/10.1016/j.joule.2018.09.021

- 72. Yan, D., Li, Y., Huo, J., Chen, R., Dai, L. and Wang, S. (2017) Defect Chemistry of Nonprecious-Metal Electrocatalysts for Oxygen Reactions. Advanced Materials, 29, Article ID: 1606459. https://doi.org/10.1002/adma.201606459

- 73. Tang, C. and Zhang, Q. (2017) Nanocarbon for Oxygen Reduction Electrocatalysis: Dopants, Edges, and Defects. Advanced Materials, 29, Article ID: 1604103. https://doi.org/10.1002/adma.201604103

- 74. Schaub, R., Wahlstrom, E., Ronnau, A., Lagsgaard, E., Stensgaard, I. and Besenbacher, F. (2003) Oxygen-Mediated Diffusion of Oxygen Vacancies on the TiO2(110) Surface. Science, 299, 377-379. https://doi.org/10.1126/science.1078962

- 75. Ouyang, C., Wang, X. and Wang, S. (2015) Phosphorus-Doped CoS2 Nanosheet Arrays as Ultra-Efficient Electrocatalysts for the Hydrogen Evolution Reaction. Chemical Communica-tions, 51, 14160-14163. https://doi.org/10.1039/C5CC05541E

- 76. Li, H., Tsai, C., Koh, A.L., Cai, L., Contryman, A.W., Fragapane, A.H., Zhao, J., Han, H.S., Manoharan, H.C., Abild-Pedersen, F., Norskov, J.K. and Zheng, X. (2016) Corrigendum: Activat-ing and Optimizing MoS2 Basal Planes for Hydrogen Evolution through the Formation of Strained Sulphur Vacancies. Nature Materials, 15, 84-53. https://doi.org/10.1038/nmat4564

- 77. Xu, L., Jiang, Q., Xiao, Z., Li, X., Huo, J., Wang, S. and Dai, L. (2016) Plasma-Engraved Co3O4 Nanosheets with Oxygen Vacancies and High Surface Area for the Oxygen Evolution Reaction. Angewandte Chemie International Editio, 55, 5277-5281. https://doi.org/10.1002/anie.201600687

- 78. Cai, Z.X., Wang, Z.L., Xia, Y.J., Lim, H., Zhou, W., Taniguchi, A., Ohtani, M., Kobiro, K., Fujita, T. and Yamauchi, Y. (2021) Tailored Catalytic Nanoframes from Metal-Organic Frame-works by Anisotropic Surface Modification and Etching for the Hydrogen Evolution Reaction. Angewandte Chemie In-ternational Edition, 60, 4747-4755. https://doi.org/10.1002/anie.202010618

- 79. Li, X., Liu, H., Sun, Y., Zhu, L., Yin, X., Sun, S., Fu, Z., Lu, Y., Wang, X. and Cheng, Z. (2020) High Oxygen Evolution Activity of Tungsten Bronze Oxides Boosted by Anchoring of Co2+ at Nb5+ Sites Accompanied by Substantial Oxygen Vacancy. Advanced Science, 7, Article ID: 2002242. https://doi.org/10.1002/advs.202002242

NOTES

*通讯作者。