Material Sciences

Vol.08 No.05(2018), Article ID:25113,8

pages

10.12677/MS.2018.85065

The Influence of Oxygen Pressure on Properties of Pulsed Laser Deposited BeMgZnO Quaternary Alloy Thin Films

Ronghuizi Yang, Mingkai Li, Gang Chang, Yinmei Lu*, Yunbin He

School of Materials Science and Engineering, Hubei University, Wuhan Hubei

Received: May 4th, 2018; accepted: May 20th, 2018; published: May 28th, 2018

ABSTRACT

BeMgZnO quaternary alloy thin films were grown on the c-plane sapphire substrates by pulsed laser deposition (PLD) method using BeMgZnO ceramics target. The films were grown at a fixed substrate temperature of 700˚C and various O2 pressures. X-ray diffraction, X-ray photoelectron spectroscopy and UV-Vis spectrophotometry were used to characterize the films. By Be-Mg co-substitution in ZnO, the solid solubility of Mg in the BeMgZnO quaternary alloy films was increased largely. Even when the Mg content reached 44.4%, no phase segregation was found in the BeMgZnO quaternary alloy thin film. Meanwhile, the band gap of the BeMgZnO film was enlarged to 4.19 eV, and its visible-light transmittance exceeded 85%.

Keywords:BeMgZnO, Quaternary Alloy, Thin Film, Co-Substitution, PLD

氧压变化对脉冲激光沉积法制备BeMgZnO 四元合金薄膜性能的影响

杨蓉慧子,黎明锴,常钢,卢寅梅*,何云斌

湖北大学材料科学与工程学院,湖北 武汉

收稿日期:2018年5月4日;录用日期:2018年5月20日;发布日期:2018年5月28日

摘 要

本工作采用脉冲激光沉积法,以BeMgZnO陶瓷为靶材、c面蓝宝石为衬底,在固定衬底温度700˚C、改变沉积氧压条件下制备BeMgZnO四元合金薄膜。采用X射线衍射、X射线光电子能谱、紫外-可见光谱法系统表征研究了这些薄膜。结果表明,通过Be-Mg共取代ZnO,有效提高了Mg在合金薄膜中的含量。当Mg的含量达到44.4%时,BeMgZnO薄膜中仍无相分离发生,并且此时BeMgZnO薄膜的带隙达到4.19 eV,在可见光波段的透过率也高达85%。

关键词 :BeMgZnO,四元合金,薄膜,共取代,脉冲激光沉积

Copyright © 2018 by authors and Hans Publishers Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

1. 引言

ZnO作为一种重要的II-VI族氧化物半导体,具有优异的光学和电学特性,从而在太阳能电池、传感器、探测器、发光二极管和激光器等领域 [1] [2] [3] 都有应用。虽然已经历了数十年的研究,ZnO依旧是当前宽禁带半导体领域研究的热点之一。

近年来,ZnO薄膜发光器件 [4] 和探测器件 [5] 正在向紫外和深紫外光器件发展。ZnO室温下的带隙宽度为3.37 eV,进一步提高ZnO的带隙是制备深紫外光器件的关键因素之一。许多研究者都选择了对ZnO薄膜进行掺杂取代的方法来调控ZnO薄膜的带隙宽度。一般掺杂取代的元素类型包括:同价阳离子掺杂(如:Be2+、Mg2+等 [6]),阴离子掺杂(如:S2−等 [7]),阴阳离子共掺 [8] [9] [10] 等。其中,Mg元素因其氧化物的禁带宽度(7.8 eV)大、化合价与Zn相同,以及Mg2+ (0.57Å)的离子半径与Zn2+ (0.60Å)的离子半径相近 [11] ,使得Mg掺杂取代ZnO得到的MgZnO三元合金薄膜具有更大的带隙宽度和较小的晶格失配,从而从众多的掺杂元素中脱颖而出。然而,由于MgO (岩盐矿)与ZnO (纤锌矿)具有不同的晶体结构,随着Mg含量的增加,MgZnO合金薄膜将发生由纤锌矿结构向岩盐矿结构的转变。Ohtomo等人首先发现当Mg含量高于33%时,MgZnO合金会发生相分离,此时Mg0.33Zn0.67O合金的带隙宽度达到了3.99 eV [12] 。为了进一步提高薄膜的带隙宽度,Su等人利用第一性原理计算方法对Be和Mg共取代ZnO的带隙调控进行了研究,理论上证明了Be-Mg共掺杂ZnO系统相较于Be掺杂ZnO系统具有更好的稳定性,并能得到更大的带隙宽度 [13] 。随后,Zhu等人在微观上解释了Be与Mg共掺杂相互稳定的机制 [14] 。这些研究表明,与MgZnO三元合金薄膜相比,四元合金薄膜BeMgZnO在高Mg含量的情况下仍可能保持单相纤锌矿结构,同时进一步增大薄膜带隙宽度。

目前,有关BeMgZnO四元合金薄膜的研究报道还很少,除了Vettumperumal等采用了溶胶凝胶方法 [15] ,大部分研究都采用分子束外延(MBE) [16] [17] 和等离子体辅助分子束外延(PA-MBE) [18] [19] 等复杂昂贵的技术来制备BeMgZnO四元合金薄膜。本工作通过简单易行的脉冲激光沉积法(PLD: pulsed laser deposition),采用自制的BeMgZnO陶瓷靶材,直接在c面蓝宝石上沉积BeMgZnO四元合金薄膜。我们发现即使在没有任何缓冲层存在的情况下,BeMgZnO四元合金薄膜在高Mg含量时,仍然可以保持单相纤锌矿结构,并具有良好的结晶质量。

2. 实验

2.1. BeMgZnO四元合金薄膜的制备

我们采用脉冲激光沉积法,以传统陶瓷烧结技术自制的BeMgZnO陶瓷作为靶材,在c-Al2O3衬底上生长BeMgZnO四元合金薄膜。脉冲激光沉积法制备薄膜原理如图1所示。实验中使用的准分子激光器(Lambda Physik COMPEX PRO 205F)的脉冲激光波长为248 nm、能量为350 mJ/pulse、重复频率为5 Hz。首先,将c面蓝宝石衬底放入管式炉中在1100˚C条件下退火1小时,消除衬底中的应力及表面吸附杂质,以利于制备高质量的BeMgZnO四元合金薄膜。退火后的衬底在丙酮、无水乙醇及去离子水中依次清洗15分钟,以去除其表面油污及其它杂质,随后用高纯氮气吹干,并固定在衬底托上立即放入真空腔内。沉积薄膜前,将真空腔的真空度抽至10−4 Pa左右。设定工艺参数:靶材自转5 r/min、基片自转10 r/min、沉积温度为700˚C、沉积时间为60分钟,通过改变通入真空腔的氧气流量,在不同氧压下(0 Pa~4 Pa)制备不同成分的薄膜样品。

2.2. BeMgZnO四元合金薄膜的表征

本工作采用四圆高分辨X射线衍射仪(HRXRD, D8 discover, Bruker, CuKα1, λ = 1.540598 Å)来分析BeMgZnO四元合金薄膜的晶体结构。薄膜各成分的含量变化用X射线光电子能谱(XPS, Escalab 250Xi, Thermo Scientific)进行表征。紫外分光光度计(UV 3600, Shimadzu)用来表征薄膜在室温下的光学性能。

3. 结果与讨论

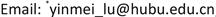

图2为BeMgZnO四元合金薄膜的X射线衍射(XRD)θ-2θ扫描图谱。从20˚到80˚的XRD全谱图(图2(a))中可以看到强度高且锐的蓝宝石衬底(006)面的衍射峰和BeMgZnO薄膜的(002)及(004)面的衍射峰,表明我们在0~4 Pa间的不同氧压条件下成功生长出了单相、具有纤锌矿结构和c面取向的BeMgZnO合金薄膜。

Figure 1. The schematic diagram for pulsed laser deposition of BeMgZnO quaternary alloy films

图1. 脉冲激光沉积法制备BeMgZnO四元合金薄膜原理示意图

(a)

(a)  (b)

(b) (c)

(c)  (d)

(d)

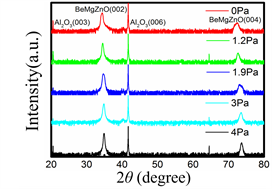

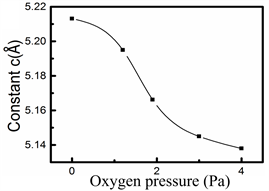

Figure 2. The θ-2θ scan XRD patterns of the BeMgZnO quaternary alloy films: (a) broad scan; (b) narrow scan; (c) The lattice constant c of the BeMgZnO quaternary alloy films as a function of the O2 pressure; (d) The XRD rocking curves of the (002)-plane of BeMgZnO quaternary alloy films

图2. (a) BeMgZnO四元合金薄膜的θ-2θ扫描XRD全谱图;(b) BeMgZnO四元合金薄膜的θ-2θ扫描XRD窄谱图;(c) BeMgZnO四元合金薄膜晶格常数c随氧压变化的曲线图;(d) BeMgZnO四元合金薄膜(002) 面的摇摆曲线图

图2(b)为BeMgZnO四元合金薄膜从33˚到36˚的XRD窄谱图。由图2(b)可以看出,随着氧压的增大,BeMgZnO薄膜(002)面的衍射峰位置逐渐向高角度方向移动,其中0 Pa氧压下制备薄膜的衍射峰2θ为34.37˚,4 Pa氧压下制备薄膜的衍射峰2θ为34.9˚。根据布拉格方程2dSinθ = nλ (n = 1),通过代入图2(b)中BeMgZnO薄膜(002)面的衍射峰2θ值,计算得到不同氧压条件下制备薄膜的晶格常数c的值,如图2(c)所示。结果显示,薄膜的晶格常数c随着氧压的增大而逐渐减小,从氧压为0 Pa时的5.213 Å逐渐减小至氧压为4 Pa时的5.138 Å。表1列出了生长过程中不同氧压条件下制备薄膜的晶格常数c的具体数值(纤锌矿ZnO晶格常数c = 5.23 Å,岩盐矿MgO晶格常数c = 4.216 Å,纤锌矿BeO晶格常数c = 4.24 Å)。图2(d)为不同氧压条件下制备BeMgZnO薄膜样品(002)面的摇摆曲线,其半高宽随着氧压的增大而减小,在4 Pa氧压时摇摆曲线的半高宽达到1.461˚,表明薄膜沿生长方向原子排列的有序度随着氧压的增大而增大,在高氧压条件下可以得到面外取向度更高的薄膜样品。表1中也列出了不同氧压条件下制备BeMgZnO薄膜样品(002)面的摇摆曲线半高宽的具体数值。

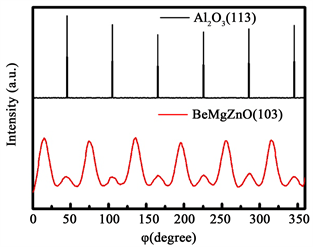

图3给出了c面蓝宝石(113)面和4 Pa氧压下生长的BeMgZnO四元合金薄膜(103)面的XRD Phi扫描图谱。根据图3可知蓝宝石衬底为六度对称结构,而BeMgZnO薄膜的Phi扫描出现了两套六度对称衍射峰,其中BeMgZnO薄膜(103)面弱峰的峰位与蓝宝石(113)面的峰位一致,这与ZnO薄膜在c面蓝宝石上生长时的结果类似,表明薄膜与蓝宝石衬底间的外延关系为BeMgZnO(100)//sapphire(110)。BeMgZnO(103)面强峰的峰位与蓝宝石(113)面的峰位相差30˚,表明此时BeMgZnO四元合金薄膜与衬底的外延关系为BeMgZnO(110)//sapphire(110)。根据上述θ-2θ扫描XRD数据(图2(a))可知,这些不同氧压条件下生长的BeMgZnO四元合金薄膜均为纤锌矿结构的单相薄膜,Phi扫描中两套六度对称峰的出现可归因为薄膜在面内出现两个相互旋转30˚的晶畴,即BeMgZnO四元合金薄膜中存在结构取向分离的现象。

Figure 3. The Phi-scans at sapphire (113) and (103) of the BeMgZnO quaternary alloy film deposited with 4 Pa of oxygen pressure

图3. 蓝宝石衬底(113)晶面和4 Pa氧压条件下制备的四元合金薄膜BeMgZnO (103)晶面的Phi扫描对比分析谱图

Table 1. The composition, lattice constant c, band gap energy, and half width of the rocking curve of BeMgZnO quaternary alloy films

表1. BeMgZnO四元合金薄膜的成分、晶格常数c、带隙宽度和XRD摇摆曲线的半高宽

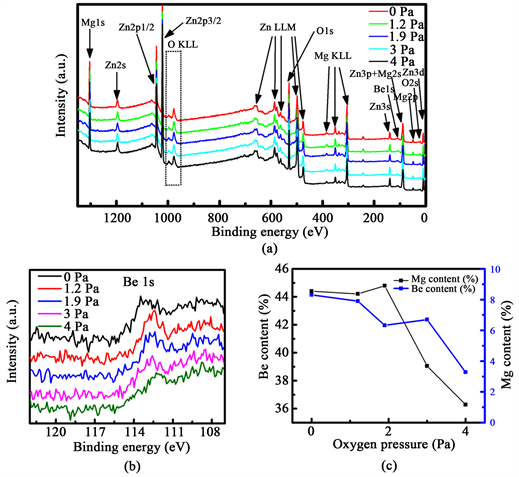

图4(a)是不同氧压下生长的BeMgZnO四元合金薄膜的XPS谱图。从图4(a)中可以看出薄膜中只有Be、Mg、Zn、O四种元素的存在,说明Be、Mg共同掺入薄膜的同时并没有引入其它杂质元素。图4(b)是在不同氧压条件下生长的BeMgZnO薄膜中Be元素的XPS窄扫描谱图。从图4(b)可看出,Be 1s的峰强很弱,且有随着沉积氧压增大而减弱的趋势。图4(c)展示了薄膜中Be、Mg含量随沉积氧压改变而变化的曲线。由图可以看出:随着氧压的增大,Be与Mg的含量都呈现减少的总趋势,其中Be、Mg含量的微小起伏可能由XPS实验测试及后期成分计算误差所造成的。通过XPS数据处理得到的Be与Mg含量具体数值见表1。由表1可以看出,薄膜生长过程中氧压的变化会明显影响BeMgZnO四元合金薄膜内各组分的含量,并且各氧压条件下生长BeMgZnO薄膜中的Mg含量均远高于文献 [8] 中报道的单相纤锌矿结构MgZnO中Mg含量的最高限度33%,表明Be、Mg共掺确实有利于提高Mg在四元合金中的固溶度。

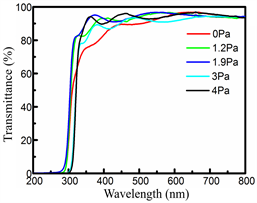

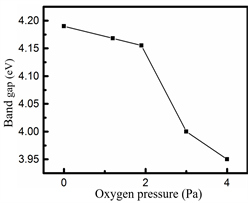

图5(a)为不同氧压条件下生长的BeMgZnO薄膜在室温下的透射光谱图。从图中可以看出薄膜在可见光区的透过率良好,均在85%以上,且薄膜生长时氧压的变化对薄膜的透过率无明显影响。由于BeMgZnO为直接带隙半导体材料 [20] ,因此其带隙可以基于公式:(ahυ)2 ∝ (hυ − Eg)通过线性外推法得到,其中a为吸收系数,hυ为光子能量。利用线性外推法得到的不同氧压条件下生长的薄膜样品的带隙宽度如图5(b)所示。从图中可以看到,薄膜的光学带隙分布于3.95 eV~4.19 eV之间。表1列出了各氧压条件下制备的BeMgZnO薄膜的带隙宽度值,其中大部分样品的带隙宽度高于文献中报道的MgZnO薄膜的最大带隙3.99 eV [12] ,且BeMgZnO薄膜的带隙宽度随着氧压的增大而逐渐减小,与其中Be、Mg含量的变化

Figure 4. (a) The XPS survey spectra and (b) the Be 1s spectra of BeMgZnO quaternary alloy films; (c) The Be and Mg contents in the BeMgZnO films as a function of the oxygen pressure

图4. (a) BeMgZnO四元合金薄膜的XPS全谱图;(b) BeMgZnO四元合金薄膜Be 1s的XPS窄谱图;(c) BeMgZnO四元合金薄膜中Be、Mg含量随氧压变化曲线图

(a)

(a)  (b)

(b)

Figure 5. (a) The optical transmittance spectra of BeMgZnO quaternary alloy films; (b) The optical band gaps of the films as a function of the oxygen pressure

图5. (a) BeMgZnO四元合金薄膜的UV-Vis透射光谱;(b) BeMgZnO四元合金薄膜的带隙宽度随生长氧压变化趋势图

趋势相符合。在BeMgZnO四元合金薄膜中,Be与Mg含量的增多均有拓宽带隙的作用。如图4(c)中所示,随着氧压增大,BeMgZnO四元合金薄膜中Be与Mg含量均减小,因此其带隙宽度也随之减小。

4. 结论

本研究通过脉冲激光沉积法,以BeMgZnO陶瓷作为靶材在c面蓝宝石上直接生长出单相的BeMgZnO四元合金薄膜,并系统地研究了生长氧压对薄膜结构、成分以及光学带隙的影响。结果表明,通过Be-Mg共取代ZnO,不仅有效地提高了Mg在纤锌矿结构ZnO中的固溶度极限,同时也提高了合金薄膜的带隙宽度。实验发现,随着生长薄膜过程中氧压的增高,BeMgZnO薄膜中的Be与Mg含量逐渐减小、Zn的含量随之升高,而薄膜中Be、Mg含量的变化直接导致了合金薄膜晶格常数c的减小、薄膜质量的提高以及带隙宽度的减小。

致谢

感谢国家自然科学基金(61274010, 11574074, 11774082);湖北省自然科学基金(2015CFA119, 2016AAA031);武汉国际科技合作项目(2016030409020222)以及材料复合新技术国家重点实验室(武汉理工大学)开放基金(2018-KF-16)对本工作的支持。

文章引用

杨蓉慧子,黎明锴,常 钢,卢寅梅,何云斌. 氧压变化对脉冲激光沉积法制备BeMgZnO四元合金薄膜性能的影响

The Influence of Oxygen Pressure on Properties of Pulsed Laser Deposited BeMgZnO Quaternary Alloy Thin Films[J]. 材料科学, 2018, 08(05): 559-566. https://doi.org/10.12677/MS.2018.85065

参考文献

- 1. Xu, L.G., Qiu, W., Chen R.F., Zhang, H.M. and Huang, W. (2018) Application of ZnO Electrode Buffer Layer in Perovs Kite Solar Cells. Acta Physico-Chimica Sinica, 34, 36-48.

- 2. Su, L.X., Zhu, Y., Yong, D.Y., Chen, M.M., Ji, X., Su, Y.Q., Gui, X.C., Pan, B.C., Xiang, R. and Tang, Z.K. (2014) Wide Range Bandgap Modulation Based on ZnO-Based Alloys and Fabrication of Solar Blind UV Detectors with High Rejection Ratio. ACS Applied Materials & Interfaces, 6, 14152-14158.

https://doi.org/10.1021/am503427u - 3. Özgür, Ü., Alivov, Y.I., Liu, C., Teke, A., Reshchikov, M.A., Doğan, S., Avrutin, V., Cho, S.J. and Morkoç, H. (2005) A Comprehensive Review of ZnO Materials and Devices. Journal of Applied Physics, 98, Article ID: 041301.

https://doi.org/10.1063/1.1992666 - 4. Lee, C.T. (2010) Fabrication Methods and Luminescent Properties of ZnO Materials for Light-Emitting Diodes. Materials, 3, 2218-2259.

https://doi.org/10.3390/ma3042218 - 5. Liu, K.W., Sakurai, M. and Aono, M. (2010) ZnO-Based Ultraviolet Photodetectors. Sensors, 10, 8604-8634.

https://doi.org/10.3390/s100908604 - 6. Yang, J.L., Liu, K.W. and Shen, D.Z. (2017) Recent Progress of ZnMgO Ultraviolet Photodetector. Chinese Physics B, 26, Article ID: 047308.

https://doi.org/10.1088/1674-1056/26/4/047308 - 7. Zhang, L., Li, L., Wang, L.H., Li, L.K., Lu, Y.M., Meyer, B.K. and He, Y.B. (2014) Tuning the Composition and Optical Band Gap of Pulsed Laser Deposited ZnO1-xSx Alloy Films by Controlling the Substrate Temperature. Journal of Alloys and Compounds, 617, 413-417.

https://doi.org/10.1016/j.jallcom.2014.08.024 - 8. Zheng, L.L., Lin, Y.Y., Li, L., Liang, G.J., Li, M.K., Li, P. and He, Y.B. (2015) Structural Properties and Enhanced Bandgap Tunability of Quaternary CdZnOS Epitaxial Films Grown by Pulsed Laser Dep-osition. Journal of Alloys and Compounds, 650, 748-752.

https://doi.org/10.1016/j.jallcom.2015.08.049 - 9. He, Y.B., Cheng, H.L., Tai, J.L., Li, L., Zhang, L., Li, M.K., Lu, Y.M., Zhang, W. and Meyer, B.K. (2015) Single-Phase Quaternary MgxZn1-xO1-ySy Alloy Thin Films Grown by Pulsed Laser Deposition. Journal of Applied Physics, 117, Article ID: 065301.

https://doi.org/10.1063/1.4907785 - 10. Zhang, W.Z., Xu, M.J., Zhang, M., Cheng, H.L., Li, M.K., Zhang, Q.F., Lu, Y.M., Chen, J.W., Chen, C.Q. and He, Y.B. (2018) Pulsed Laser Deposited BexZn1-xO1-ySy Quaternary Alloy Films: Structure, Composition, and Band Gap Bowing. Applied Surface Science, 433, 674-679.

https://doi.org/10.1016/j.apsusc.2017.10.068 - 11. Ghosh, R. and Basak, D. (2007) Composition Dependent Ultraviolet Photoresponse in MgxZn1-xO Thin Films. Journal of Applied Physics, 101, Article ID: 113111.

https://doi.org/10.1063/1.2743887 - 12. Ohtomo, A., Kawasaki, M., Koida, T., Masubuchi, K., Koinuma, H., Sakurai, Y., Yoshida, Y., Yasuda, Y. and Segawa, Y. (1998) MgxZn1 xO as a II-VI Widegap Semiconductor Alloy. Applied Physics Letters, 72, 2466-2468.

https://doi.org/10.1063/1.121384 - 13. Su, X.Y., Si, P.P., Hou, Q.Y., Kong, X.L. and Cheng, W. (2009) First-Principles Study on the Bandgap Modulation of Be and Mg Co-Doped ZnO Systems. Physica B: Condensed Matter, 404, 1794-1798.

https://doi.org/10.1016/j.physb.2009.02.021 - 14. Zhu, Y., Su, L.X., Chen, M.M., Su, Y.Q., Ji, X., Gui, X.C. and Tang, Z.K. (2015) Controlled Growth of Epitaxial Wurtzite BeMgZnO Alloy Films and Two Microscopic Origins of Be-Mg Mutual Stabilizing Mechanism. Journal of Alloys and Compounds, 631, 355-359.

https://doi.org/10.1016/j.jallcom.2015.01.173 - 15. Vettumperumal, R., Kalyanaraman, S. and Thangavel, R. (2013) Nano-crystalline Zn1−x−yBexMgyO Thin Films Synthesized by the Sol-Gel Method: Structural and Near Infrared Photoluminescence Proper-ties. Journal of Sol-Gel Science and Technology, 68, 334-440.

https://doi.org/10.1007/s10971-013-3174-7 - 16. Ullah, M.B., Ding, K., Nakagawara, T., Avrutin, V., Ozgur, U. and Morkoc, H. (2018) Characterization of Ag Schottky Barriers on Be0.02Mg0.26ZnO/ZnO Heterostructures. Physica Status Solidi-Rapid Research Letters, 12, Article ID: 1700366.

https://doi.org/10.1002/pssr.201700366 - 17. Ding, K., Ullah, M.B., Avrutin, V., Ozgur, U. and Morkoc, H. (2017) Investi-gation of High Density Two-Dimensional Electron Gas in Zn-Polar BeMgZnO/ZnO Heterostructures. Applied Physics Letters, 111, Article ID: 182101.

https://doi.org/10.1063/1.4993853 - 18. Toporkov, M., Ullah, M.B., Demchenko, D.O., Avrutin, V., Morkoç, H. and Özgür, Ü. (2017) Effect of Oxygen-to-Metal Flux Ratio on Incorporation of Metal Species into Quaternary BeMgZnO Grown by Plas-ma-Assisted Molecular Beam Epitaxy. Journal of Crystal Growth, 467, 145-149.

https://doi.org/10.1016/j.jcrysgro.2017.03.028 - 19. Chen, S.S., Pan, X.H., Li, Y.G., Chen, W., Zhang, H.H., Dai, W., Ding, P., Huang, J.Y., Lu, B. and Ye, Z.Z. (2015) Improved Photoluminescence Performance of MgZnO Films by Alloying Beryllium. Physics Letters A, 379, 912-915.

https://doi.org/10.1016/j.physleta.2015.01.009 - 20. Toporkov, M., Avrutin, V., Okur, S., Izyumskaya, N., emchenko, D.D., Volk, J., Smith, D.J., Morkoç, H. and Özgür, Ü. (2014) Enhancement of Be and Mg Incorporation in Wurtzite Quaternary BeMgZnO Alloys with up to 5.1 eV Optical Bandgap. Journal of Crystal Growth, 402, 60-64.

https://doi.org/10.1016/j.jcrysgro.2014.04.028

NOTES

*通讯作者。