Advances in Energy and Power Engineering

Vol.

09

No.

03

(

2021

), Article ID:

42899

,

14

pages

10.12677/AEPE.2021.93013

三维多孔锂离子和锂硫电池阴极的研究进展

李舒冰1,2,费奔3*

1东华大学纤维材料改性国家重点实验室,上海

2东华大学材料科学与工程学院,上海

3复旦大学材料系,上海

收稿日期:2021年5月7日;录用日期:2021年5月21日;发布日期:2021年6月3日

摘要

锂离子电池和Li-S电池因其能量密度高、自放电低等特点而受到人们的广泛关注。新兴的应用要求电池具有更高的性能因素,如容量和循环寿命,这促使许多研究努力构建高性能的正负极材料。其中,阴极材料是近年来研究的重点。低电子和离子电导率和较差的电极稳定性仍然是巨大的挑战。三维(3D)多孔纳米结构通常表现出独特的性能,如良好的Li+离子扩散,短的电子传递路径,强大的机械强度,以及充/放电过程中有足够的空间来调节体积变化,这使得它们有希望成为高性能电池阴极。本文综述了锂离子和锂硫电池阴极的一些前沿研究。

关键词

锂电池,锂硫电池,容量,循环,3D多孔纳米结构

Research Progress on Three-Dimensionally Porous Li-Ion and Li-S Battery Cathodes

Shubing Li1,2, Ben Fei3*

1State Key Laboratory for Modification of Chemical Fiber and Polymer Materials, Shanghai

2College of Materials Science and Engineering of Donghua University, Shanghai

3Department of Material Science, Fudan University, Shanghai

Received: May 7th, 2021; accepted: May 21st, 2021; published: Jun. 3rd, 2021

ABSTRACT

Li-ion batteries and Li-S batteries have attracted extensive attention because of their high energy density and low self-discharge. Emerging applications require batteries with higher performance factors, such as capacity and cycle life, which has prompted many research efforts to construct high-performance anode and anode materials. Among them, cathode material is the focus of research in recent years. Low electron and ionic conductivity and poor electrode stability remain significant challenges. Three-dimensional (3D) porous nanostructures usually exhibit unique properties such as good Li+ ion diffusion, short electron transfer path, strong mechanical strength, and enough space to adjust volume changes during charge/discharge, which makes them promising as high-performance battery cathodes. In this paper, some advanced researches on cathode of lithium-ion and lithium-sulfur battery are reviewed.

Keywords:Lithium Battery, Lithium Sulfur Battery, Capacity, Cycles, 3D Porous Nanostructures

Copyright © 2021 by author(s) and Hans Publishers Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY 4.0).

http://creativecommons.org/licenses/by/4.0/

1. 前言

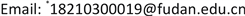

可充电电池广泛应用于应急电源备份、电动汽车、太阳能储能、便携式设备、可穿戴电子产品等领域 [1] [2]。其中,锂离子电池和Li-S电池相对于其他电池具有竞争优势 [3] - [9]。锂离子电池的原理是在充放电过程中锂离子在电极上的插入和提取 [10] [11] [12] [13],如图1所示。电池外部的电流由外部电路的电子以与锂离子相反的方向传递。对于Li-s电池,如图2所示,S8与锂离子反应生成高阶锂多硫化物Li2Sx (4 < x < 8),然后随着锂离子的连续插入形成低价态锂多硫化物Li2Sx (2 < x < 4) [14] [15] [16]。

Figure 1. Schematic illustration for the working mechanism of a typical LiFePO4 cathode-based Li-ion battery. Reproduced with permission from [12]

图1. 典型的LiFePO4阴极基锂离子电池的工作机理示意图 [12]

目前,正极材料是高性能锂离子电池和Li-S电池发展的重点之一 [17] [18]。许多阴极材料几乎具有多孔特性,具有扩大比表面积、增加比容量和能够克服体积变化的优点。在各种结构中,三维多孔结构被认为是一种非常理想的结构。

为了进一步提高锂离子电池中锂离子的脱/嵌动力学以及锂离子与锂离子之间的反应动力学,可以通过构建三维多孔结构来实现。此外,三维多孔结构具有多个孔隙空间,能够改善与电解质的接触。但是在充放电过程中需要一部分电解液来湿润活性材料,因此3D结构会消耗更多的电解液 [19] [20] [21]。此外,3D电极中减少的材料负载也需要在实际应用中加以改进。三维多孔电极的优点和缺点使其成为一个有吸引力的深入研究领域。在此,我们重点研究了用于锂离子电池和锂硫电池的三维多孔正极材料及其制备方法。

(a) (b)

(a) (b)

Figure 2. (a) Illustration of a Li-S battery and the (b) electrochemical species formed during lithiation [14]

图2. (a) Li-S电池的说明和(b)在锂化过程中形成的电化学物质 [14]

2. 锂离子电池和锂硫电池阴极面临的挑战

锂离子电池的性能在一定程度上取决于阴极所用材料的固有性能。对于正极材料,优先考虑高比容量、高电势、大离子和电子传输速率、长寿命。目前,阴极材料多为锂基嵌层化合物。研究了可用的化合物,如LiNiO2,LiCoO2和LiMnO2,用于阴极应用。为了获得高能量密度,一些由多个金属原子组成的化合物,如LiNi1/3Co1/3Mn1/3O2 (NCM),有望取代部分单一金属化合物 [22]。具有MO6八面体(M为Fe、Mg或V)和XO4 n-四面体阴离子(X为Si或P)的化合物可以调节过渡金属的氧化还原电位,如Fe3+/Fe2+。然而,这类化合物有一个共同的基本问题,即电导率差,降低了电化学性能。

与锂离子电池相比,Li-S电池具有更高的理论能量密度(2600 Wh∙kg−1)和更好的容量(1672 mAh∙g−1) [23]。然而,硫的问题需要解决。首先,单质硫是一种天然的绝缘体(5 × 10−30 S∙cm−1),它绝对限制了电子的运动。放电过程中形成的长链聚硫锂容易溶解在有机电解质中。当这些多硫化物通过电解质扩散到阳极,并与锂阳极反应时,这种反应被称为穿梭机制。在长链和短链锂多硫化物过渡过程中,会消耗部分电能,这一意想不到的现象制约了电效率。同时,这种不受控制的反应会产生不稳定的膜。因此,固体电解质界面(SEI)膜的不稳定性会对Li-S电池的循环稳定性产生负面影响。硫的质量密度(2.03 g∙cm−3)比Li2S的质量密度(1.67 g∙cm−3)大20%左右,导致了充放电过程中不可忽视的收缩和膨胀。最后,由于锂离子从电解质中沉积,锂电极的形貌发生了变化。为了保证电池的安全性,应去除电极表面生长的锂枝晶 [24]。

3. 三维多孔锂离子电池阴极的制备方法

3.1. 水热合成法

水热法包括在高压下从高温水溶液中结晶材料的各种技术。与其他几种类型的晶体生长相比,水热法能够产生在熔点不稳定的晶体相。此外,在熔点附近具有高蒸汽压的材料可以通过水热法生长。这些优点使得水热法适用于构建多种电池三维电极。本节主要介绍水热法。

传统的LiFePO4阴极电导率较差(~10−9 S∙cm−1),锂离子扩散速度慢,限制了其广泛应用。为了提高LiFePO4的电导率和离子输运率,人们采用了多种方法,包括将LiFePO4的尺寸缩小到纳米级,在颗粒上涂上导电材料,或通过结构制造来扩大表面积。为了提高锂电池的高倍率放电容量,我们构建了一种碳层包覆LiFePO4的三维集电极。此外,直径在70~100 nm的LiFePO4纳米颗粒上的碳层保护了这些颗粒,也有助于提高的电导率。此外,由镍和铬制成的多孔衬底不仅提高了导电性,而且产生了较大的表面积 [25]。

Du等报道了一种原位一锅水热法制备导电石墨烯(G)/LiFePO4复合材料的简便方法 [26]。当LiFePO4纳米颗粒负载在3D石墨烯网络上时,可以实现快速电子传输和短的锂离子转移路径。3 D G /磷酸铁锂复合材料表现出高容量的160 mAh∙g−1在0.2C (94.12%的理论容量170 mAh∙g−1),在10C下115 mAh∙g−1的倍率性能(初始容量的71.9%),和良好的循环性能94.2%的容量保留100个周期后,所有这些都显示了它们在高倍率锂离子电池中的潜在应用。

Fu等人 [27] 提出了一种新型的0.5Li2MnO3∙0.5LiMn0.4Co0.3Ni0.3O2空心分层结构复合材料,其形貌呈花状。纳米板内部的空腔组成了完整的花状复合材料,这表明中空的壳层可以为电解质和离子提供通道。放电容量分别为296.5、270.6、243.6、207.8和187.4 mAh∙g−1,放电速率分别为0.2、0.5、1、3和5 C。在0.5℃条件下,100次循环后容量保持率超过87%,容量衰减率为0.13%每循环。

Li3V2(PO4)3具有单斜晶结构,具有高工作电位4.8 V,理论容量197 mAh∙g−1,能量密度800 Wh∙kg−1 [28] 等特性,是锂离子电池正极材料的理想材料。Li3V2(PO4)3相由一个略微扭曲的VO6八面体和PO4四面体共享氧顶点的3D框架组成,在相对较大的间隙位置承载Li离子,导致离子快速传输。Cui等采用水热法 [29] 制备了石墨烯纳米片和碳纳米管修饰的碳包覆Li3V2(PO4)3纳米晶体,如图3所示。石墨烯纳米片和碳纳米管相互连接形成三维导电网络,该网络也支持Li3V2(PO4)3粒子。当使用石墨烯片时,聚集的Li3V2(PO4)3/C纳米颗粒负载在石墨烯片上,形成三维层状结构。当碳纳米管也被使用时,每个石墨烯层之间的互连得到了改善。碳纳米管增强了结构强度,并为电子转移提供了途径。从复合材料杂乱的结构来看,复合材料具有显著的高速率性能和长周期稳定性。在20℃、3.0~4.8 V电位范围内,初始放电容量为147.5 mAh∙g−1。2000次循环后容量保持率为82.7%。

五氧化钒(V2O5)是一种典型的嵌层化合物。它具有层状结构,可以通过V2O5 + xLi+ + xe− ↔ LixV2O5反应接受一个以上的电子和锂离子。但V2O5也有不足之处,其导电性中等,为10−4~10−5 S∙cm−1,Li+扩散系数较低,为10~12 cm2∙s−1 [30]。众所周知,无粘结剂技术将活性材料负载在电流集电极上,无需任何粘结剂和导电粘合剂,从而简化了电池电极。目前已经报道了许多独立的3D多孔V2O5电极。例如,Gao等人报道了一步水热法将五氧化二钒颗粒限制在3D N掺杂石墨烯中作为独立阴极 [31]。氮掺杂石墨烯良好的导电性能和弹性性能得到了有效利用。复合阴极具有在100 mA∙g−1下283 mAh∙g−1高容量和1 A∙g−1下134 mAh∙g−1的倍率性能。

Figure 3. Schematic illustration of preparing nanosized Li3V2(PO4)3/C (C-LVP), carbon nanotube modified Li3V2(PO4)3/C (C-LVP/GNS), graphene nanosheet, and carbon nanotube co-modified Li3V2(PO4)3/C (C-LVP/(GNS+CNT)) composites via a hydrothermal-assisted sol-gel route [29]

图3. 通过水热辅助溶胶–凝胶路线 [29] 制备纳米级Li3V2(PO4)3/C (C-LVP)、碳纳米管修饰的Li3V2(PO4)3/C (C-LVP/GNS)、石墨烯纳米片和碳纳米管共修饰的Li3V2(PO4)3/C (C-LVP/(GNS+CNT))复合材料示意图

此外,由于三维分层纳米结构可以抑制锂离子的团聚,改善锂离子的扩散,因此在电极中得到了广泛的应用。Pan等发现不同浓度的草酸钒前体(VOC2O4)对产物 [32] 的形貌有影响。如图4所示,他们报道了一种简单的溶剂热方法,通过调节VOC2O4的浓度和持续时间来制备分级的氧化钒纳米和微观结构。首先在不含表面活性剂的情况下,通过自组装合成了海胆状的VO2微花,然后通过煅烧将VO2转化为海胆状的V2O5微结构。V2O5微观结构由纳米带和纳米棒组成,其中具有高孔隙结构。所得V2O5的比表面积为33.64 m2∙g−1,这与V2O5具有三维分层多孔结构和砌块表面积大有关。此外,作为阴极材料,在电流密度为300 mAh∙g−1时,V2O5阴极具有267 mAh∙g−1的高比放电容量。

Figure 4. SEM images of the 3D vanadium oxide obtained after different solvothermal reaction time: (a), (b) VO-0.5 h, (c), (d) VO-2 h, and (e), (f) VO-24 h [32]

图4. 不同溶剂热反应时间得到的3D氧化钒的SEM图像为:(a),(b) VO-0.5 h,(c),(d) VO-2 h,(e),(f) VO-24 h [32]

Guo等报道了一种简单的水热法制备精细的V2O5-SnO2/CNTs复合材料的方法,该方法将纳米级的V2O5涂层和碳纳米管(CNTs)通过SnO2纳米颗粒 [33] 连接。经过热处理后,复合材料被证实是多孔的,因为CNTs堆积。CNTs的外表面均匀覆盖了SnO2和V2O5,具有良好的导电性,提高了循环容量和速率容量。在2.05~4.0 V范围内,V2O5-SnO2/CNTs复合阴极的初始放电容量为250 mAh∙g−1。此外,所有循环的库仑效率都达到了99%以上,显示出良好的循环稳定性。

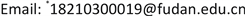

Li等人提出了一种将活性材料与石墨烯 [34] 相结合,制作三维结构电极的简易方法。如图5所示,我们利用3D逆蛋白石模板制备了阴极V2O5@石墨烯@V2O5的三明治状结构。首先,在聚苯乙烯蛋白石模板上电沉积镍反蛋白石,然后通过化学气相沉积在该模板上生长石墨烯。在镍刻蚀过程中,在石墨烯的外表面生长了一层V2O5。然后,将另一层V2O5生长到石墨烯内层,形成3D V2O5@石墨烯@V2O5复合材料。该阴极在200次循环后提供了约230 mAh∙g−1的全电极基容量,2000次循环后提供了203 mAh∙g−1的库仑效率为99.7%。

Figure 5. Schematic illustration for the fabrication of the 3D sandwich-structured V2O5@graphene@V2O5 cathode [34]

图5. 三维夹层结构V2O5@石墨烯@V2O5阴极的制备示意图 [34]

3.2. 溶胶–凝胶法

另一种广泛使用的3D电极制备方法是溶胶–凝胶法。例如,Park等报道了以聚苯乙烯珠为模板制备3D LiMn2O4薄膜的溶胶–凝胶法。首先在基底表面沉积一层聚苯乙烯微球,这是制造在垂直方向 [35] 上没有重叠的开放体积的基础。随后,将制备的含有前驱体材料的溶剂浸入到衬底上。沉积膜煅烧后,聚苯乙烯模板通过热分解去除。前驱体转化为LiMn2O4。最后,形成了一种具有反蛋白石结构的三维球形多孔结构。结果表明,放电容量与退火温度有关,退火温度对组织的稳定性有较大的影响。Zhang等人通过溶胶–凝胶法 [36] 成功地将Li3V2(PO4)3纳米粒子包裹在非晶态碳中。薄碳层和碳网络的存在有利于Li+的输运和电子导电性。该材料作为阴极,在30℃的高速率下,其容量为85 mAh∙g−1。

Li等人报道了一种溶胶–凝胶法构建用于 [37] 锂离子电池的3D LiAlO2-LiMnPO4/C。LiAiO2模板首先由阳极氧化铝(AAO)模板构建。然后,LiMnPO4/C填充制备的模板孔,最终形成蜂窝状结构。该材料作为锂离子电池的正极材料,在10 C下循环100次后,表现出105 mAh∙g−1的高容量和98.4%的保存率。由于其特殊的核壳结构,电化学性能得到了改善。Ragupathi等报道了一种溶胶–凝胶法合成球形LiCoBO3,用于锂离子电池 [38] 的正极材料。所制备的材料在10C下经过52次循环后的容量为98 mAh∙g−1。该材料的电化学性能优于其他通过不同方法得到的材料,这可能是由于其形成的球形有利于电子运动和锂离子扩散。

溶胶–凝胶法成本低,操作简单,适合制备高收率电极。特别是工业生产总是包含溶胶–凝胶制剂。

3.3. 固相方法

尽管采用了上述湿化学方法,但一些以固体为基础的方法也引起了广泛关注。Wang等利用MnCO3 [39] 热分解得到的Mn2O3球的孔隙率,成功地利用拓扑化学反应路线合成了纳米晶组装的多孔LiMn2O4球。TEM和N2吸附–脱附测试结果表明,整个LiMn2O4微球的平均尺寸约为45 nm。结果表明,LiMn2O4微球内部充满了丰富的孔隙,具有良好的容量和循环性能。放电容量为83 mAh∙g−1,放电速率为20 C,这可能是由于多孔通道适合锂离子扩散。

Huang等人 [40] 以石墨烯和碳纳米管导电液体(GNL)为模板,合成了多孔Li1.2Mn0.534Ni0.133Co0.133O2,如图6所示。在GNL中,CNTs均匀分布在石墨烯片层上。该复合材料的制备工艺依赖于通过高温煅烧过渡金属碳酸盐球形前驱体制备Li1.2Mn0.534Ni0.133Co0.133O2。对于具有球形粒子的多孔GNL-LMNCO,二次粒子由一次粒子组成,一次粒子的大小为150~180 nm。二次粒子的球体大小基本相同,为2.0 mm。从初生颗粒的堆积中可以明显地发现大量的孔隙。该多孔富锂阴极在100次充放电循环后仍具有235.5 mAh∙g−1的放电容量,与初始容量相比容量保持率高达86.2%。

Figure 6. Formation mechanism of the porous graphene and carbon nanotube conductive liquid-Li1.2Mn0.534Ni0.133Co0.133O2 cathode [40]

图6. 多孔石墨烯与碳纳米管导电液体-Li1.2Mn0.534Ni0.133Co0.133O2阴极 [40] 的形成机理

de Biasi等人通过固态反应方法 [41] 合成了一种三元共聚物型晶体结构LiCaFeF6。这种材料的d的性能主要归因于它的安全性和循环寿命。作为正极材料时,其放电容量为112 mAh∙g−1,最大放电电流为2.86 V。这归因于Fe3+还原为Fe2+。Baster等合成了一系列锂离子电池正极材料LiNi0.6Co0.4−ZTiZO2 (z = 0.1, 0.2, 0.3),并比较了其结构、传输和电化学性能 [42]。三种材料中,LiNi0.6Co0.3Ti0.1O2在20℃时的放电容量为100 mAh∙g−1。

3.4. 其他方法

与上述方法不同的是,制作锂离子电池3D阴极还有其他一些制备方法,包括冷冻干燥、化学气相沉积、真空过滤等。如Doherty等合成了不同直径的聚甲基丙烯酸甲酯微球作为胶体晶体模板,制备了具有特征孔 [43] 的LiFePO4。使用胶体晶体模板可以检查孔径对电化学性能的影响。气孔最大的材料直径在100 nm左右,0.1 C时放电容量为160 mAh∙g−1,5 C时放电容量为115 mAh∙g−1。

Tu等采用冷冻干燥法 [44] 制备了均匀分散的氮掺杂碳纳米管(N-CNTs)修饰的3D多孔LiFePO4材料。它包括快速冷冻、真空冷冻干燥和加热处理三个步骤。合成的多孔LiFePO4/NCNTs复合材料在0.1 C时的比容量为159 mAh∙g−1,在10 C时的比容量为72 mAh∙g−1,在500次充放电循环后的容量保持率为96.7%。

Zhao等人通过原位碳热还原 [45] 合成了斜方晶LiMnO2纳米棒。该方法包括两个步骤:MnO2纳米棒的制备和碳热还原得到LiMnO2。该材料作为锂离子电池的正极材料,在0.1 C下具有165.3 mAh∙g−1的电化学性能,40次循环后保持率为92.6%。对于锰酸盐,Duan等人在含氟氧化锡玻璃 [46] 上通过改性静电纺丝技术合成了具有多孔结构的LiMn2O4中空纳米纤维。由这些空心材料制成的阴极的比容量为125.9 mAh∙g−1,在0.1 C下循环400次后的循环性能为105.2 mAh∙g−1,表现出良好的电池性能。

以纳米颗粒 [47] 为催化剂,制备了一种具有狼牙棒状结构的三维Li3V2(PO4)3/C纳米线和纳米纤维膜。制造工艺结合了一种改进的静电纺丝方法与热压处理。纤维表面覆盖着原位生长的纳米线,形成狼牙棒状的形态。根据复合材料的力学性能,该长程网状膜可直接用于自持阴极。所制备的阴极在3.0~4.8 V电压范围内表现出良好的速率性能和循环稳定性。放电容量分别为115.3 mAh∙g−1和108.6 mAh∙g−1,5 C和10 C。在容量保持方面,500次循环后为81.4%,1000次循环后为78.8%,稳定性较好。Li等人通过简单浸渍法 [48] 成功合成了具有三维泡沫核结构的Li3V2(PO4)3/C复合材料。观察到均匀的Li3V2(PO4)3/C气泡。将Li3V2(PO4)3纳米粒子均匀地包覆在非晶碳层上。该阴极在3.0~4.3 V电位范围内,15C比容量为100 mAh∙g−1,表现出良好的速率性能,这归因于其具有3D多孔蛙卵状结构。Zhu等报道了3D微孔石墨烯-Li2FeSiO4/C纳米复合材料 [49] 的合成。如图7所示,我们采用模板组装的方法获得了三维多孔石墨烯骨架。在制备过程中,表面接枝带正电荷的SiO2球与带负电荷的氧化石墨烯(GO)薄片通过静电相互作用组装在一起。然后将SiO2球移除,形成3D多孔石墨烯框架。最后,对Li2FeSiO4前驱体凝胶进行包覆和退火,得到3D G/Li2FeSiO4/C复合材料。该复合材料具有三维结构的孔隙率和石墨烯的导电性,在1C下放电容量可达255 mAh∙g−1。

Figure 7. Illustrations of the synthesis procedures of (a) the 3D porous graphene and (b) the graphene/ Li2FeSiO4/C composite [49]

图7. 说明了(a)三维多孔石墨烯和(b)石墨烯/Li2FeSiO4/C复合材料的合成过程 [49]

此外,通过真空过滤 [50] 法合成了一种灵活、独立、重量轻的LiMnTiO4/MWCNT。制备的材料具有三维结构,其中CNT网络被LiMnTiO4粒子包裹。该材料具有灵活性、低重量、高机械性能等优越的性能,这种材料被用作独立的阴极和提供一个容量为161 mAh∙g−1和在0.5 C循环50个周期后可以保持86.4%,这可能是多孔结构由于促进Li+和电子转换。

4. 三维多孔锂硫电池阴极的构造方法及其比较

4.1. 3D多孔S阴极

单质硫本身不能作为锂硫电池的阴极有几个原因。一是硫具有绝缘性,没有形成固体结构的牢固晶体。在这种情况下,硫与锂离子反应后,生成的Li2S不能固定在原位。另一种方法是将硫与其他导电材料结合。通过将硫涂在具有良好导电性、大表面和多孔结构的框架上,框架策略是很有前途的和可行的解决单质硫问题的方法 [51] [52] [53]。到目前为止,碳材料、导电聚合物和金属或金属氧化物已被用于硫基阴极材料的研究。锂硫电池中储存的能量与硫的质量密切相关。因此,需要三维多孔结构来增加质量载荷。

包括碳纳米管、石墨烯、碳纳米纤维、碳球和介孔碳在内的各种碳基体已被选择作为Li-S电池的骨架。此外,新概念结构的制造也很有吸引力。例如,Lu等人报道了一种组装硫–石墨烯海绵的方法,将硫均匀分布到石墨烯海绵的孔隙中 [54]。石墨烯海绵骨架不仅能提高电子导电性,还能适应充放电过程中的体积变化。经300次循环后,石墨烯层的比表面积为4.53 mAh∙cm−2,在0.1 C条件下,300次循环后,石墨烯层的衰减速率为0.08%。在一定程度上,交错石墨烯层可以吸收多硫化物中间产物。

Li等人报道了一种新型3D分层聚吡咯负载硫 [55]。首先,以硅溶胶晶体为模板,合成了比表面积大的三维聚吡咯。随后,通过溶液–扩散途径将硫装载到聚吡咯表面,然后进行低温处理。当用作锂硫电池的阴极时,这种材料在0.1 C下100次循环后显示出751 mAh∙g−1的高比容量。此外,还研究了一种由化学气相沉积制备的木材激发的多通道石墨烯结构 [56]。这种独特的结构提供了一个巨大的内部空间,可以容纳硫并固定生成的多硫化物。同时,三维多通道网络也促进了质量输运和离子扩散。这些性能的好处是,MCTG/S阴极的锂S电池在0.1 C提供了放电容量1390 mAh∙g−1。

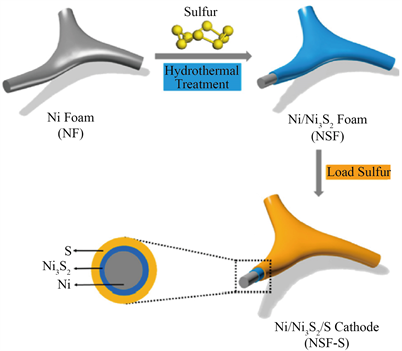

两种复合材料ZnO@S/CNT和Ni(OH)2@S/CNT,并在Li-S电池中应用 [57]。ZnO@S/CNT的初始容量为1663 mAh∙g−1,70次循环后的保留率为56.6%。根据密度泛函理论(DFT)的计算,可以归结为ZnO与 之间的强相互作用。Li等人通过水热法合成Ni3S2并将其涂覆在泡沫镍表面,然后物理涂覆S元素,最终得到三维Ni/Ni3S2/S [58]。如图8所示,金属Ni与硫的反应在泡沫Ni表面原位生成Ni3S2。杂化体内部的镍金属网络可以作为电子传递途径,促进电化学反应。此外,充足的孔隙空间使高硫负荷和承受由硫引起的体积变化。当负载量为4 mg∙cm−2时,经过100次循环后,该材料的放电容量为441 mAh∙g−1。

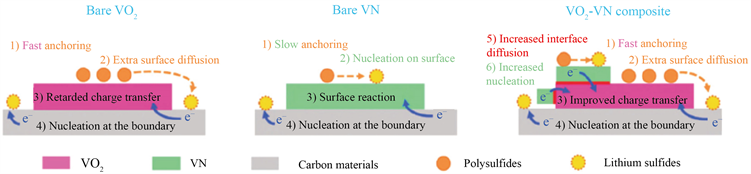

采用原位构筑的方法可以制备氧化基复合材料。例如,Song等人报道VO2-VN是Li-S电池的优良硫宿主 [59]。S@VO2-VN阴极的额定容量显示935 mAh∙g−1和在2C下循环800圈后保留56.1%。如图9所示,良好的性能归因于改进的界面接触最大和原位VN组合的结构保证LiPSs从VO2快速扩散到VN,从而提高了转化率,加速了Li2S沉淀的氧化还原动力学。

本文综述几种氧化物基阴极对Li2S2、Li2S4和Li2S6等多硫化物具有吸附能力。降低Li-S电池的穿梭效应是必要的,从而提高稳定性。相比之下,硫基阴极通常由于多硫化物的溶解和转移而遭受活性物质的损失。相对较高的负载对于硫基阴极更有吸引力,因为氧化物宿主通常比电极内的活性成分硫的重量和体积大。对于锂离子电池正极的制备,许多锂离子电池正极的制备技术也同样适用。

4.2. 锂离子电池与锂硫电池的简要比较

锂离子电池具有安全性好、工作电压高、循环比容量小、循环性能长、自放电小等优点。同时,对于Li-S电池,容量通常在700到1500 mAh∙g−1。然而,锂离子电池也面临着一些挑战,如多硫化物在电解质中的溶解,硫的导电性差,以及体积变化对活性物质的损害。例如,S的导电性意味着需要在阴极中添加更多的导电碳和聚合物粘结剂,从而降低了电极内活性物质的质量含量。因此,在实际应用中,提高锂离子电池的容量,增加锂离子电池中硫的负载是实现良好能量密度的必要条件。

Figure 8. Schematic illustration of the Ni/Ni3S2/S hybrid cathode [58]

图8. Ni/Ni3S2/S混合阴极示意图 [58]

(a) (b) (c)

(a) (b) (c)

Figure 9. llustration of LiPS anchoring-diffusion-conversion processes on VO2, VN, and VO2-VN binary host surfaces [59]

图9. LiPS在VO2、VN和VO2-VN二元宿主表面上的锚定–扩散–转换过程示意图 [59]

5. 总结

本文综述了锂离子和锂硫电池三维多孔结构电极的一些重要研究进展。与传统的厚膜电极相比,3D多孔电极能够实现快速的电子和锂离子转移,以及强大的机械强度,以及充放电过程中足够的体积变化调节空间。然而,3D多孔电极通常消耗更多的电解质,这需要在未来的研究中加以解决。因此需要构建轻质3D框架和优化多孔结构。对于这种设计和优化,可用一些人工智能(AI)方法,如遗传规划和自动神经网络 [60]。他们能够建立优化电动汽车电池包外壳的模型,并分析电极的容量 [61] [62],可以实现最佳的3d结构电极 [63]。本文介绍了锂离子电池中原始和修饰形式的3D多孔结构的LiCoO2、LiMn2O4、LiFePO4、V2O5、LiNi1−x−yCoxMnyO2,以及锂离子电池中3D纳米框架负载的S。重点介绍了模板导向化学气相沉积法、水热合成法、原子层沉积法以及相关的电化学性能。此外,3D多孔结构材料有望成为下一代阴极,这将有利于开发高性能的先进二次电池。

文章引用

李舒冰,费 奔. 三维多孔锂离子和锂硫电池阴极的研究进展

Research Progress on Three-Dimensionally Porous Li-Ion and Li-S Battery Cathodes[J]. 电力与能源进展, 2021, 09(03): 118-131. https://doi.org/10.12677/AEPE.2021.93013

参考文献

- 1. Blomgren, G.E. (2017) The Development and Future of Lithium Ion Batteries. Journal of the Electrochemical Society, 164, A5019-A5025. https://doi.org/10.1149/2.0251701jes

- 2. Seh, Z., Sun, Y., Zhang, Q. and Cui, Y. (2016) Designing High-Energy Lithium-Sulfur Batteries. Chemical Society Reviews, 45, 5605-5634. https://doi.org/10.1039/C5CS00410A

- 3. Myung, S.T., Maglia, F., Park, K.J., Yoon, C.S., Lamp, P., Kim, S.J. and Sun, Y.K. (2017) Nickel-Rich Layered Cathode Materials for Automotive Lithium-Ion Batteries: Achievements and Perspectives. ACS Energy Letters, 2, 196-223. https://doi.org/10.1021/acsenergylett.6b00594

- 4. Shi, J., Xiao, D., Ge, M., Yu, X., Chu, Y., Huang, X., Zhang, X., Yin, Y., Yang, X., Guo, Y., Gu, L. and Wan, L. (2018) High-Capacity Cathode Material with High Voltage for Li-Ion Batteries. Advanced Materials, 30, Article ID: 1705575. https://doi.org/10.1002/adma.201705575

- 5. Wang, K.X., Li, X.H. and Chen, J.S. (2015) Surface and Interface Engineering of Electrode Materials for Lithium-Ion Batteries. Advanced Materials, 27, 527-545. https://doi.org/10.1002/adma.201402962

- 6. Shen, S., Xia, X.-H., Xie, D., Yao, Z.J., Zhong, Y., Zhan, J.Y., Wang, D.H., Wu, J.B., Wang, X.L. and Tu, J.P. (2017) Encapsulating Silicon Nanoparticles into Mesoporous Carbon Forming Pomegranate Structured Microspheres as a High-Performance Anode for Lithium Ion Batteries. Journal of Ma-terials Chemistry A, 5, 11197-11203. https://doi.org/10.1039/C7TA03294C

- 7. Wang, X.F., Feng, Z.J., Huang, J.T., Deng, W., Li, H.B., Zhang, H.S. and Wen, Z.H. (2018) Graphene-Decorated Carbon-Coated LiFePO4 Nanospheres as a High-Performance Cathode Ma-terial for Lithium-Ion Batteries. Carbon, 127, 149-157. https://doi.org/10.1016/j.carbon.2017.10.101

- 8. Li, C.X., Xi, Z.C., Guo, D.X., Chen, X.J. and Yin, L.W. (2018) Chemical Immobilization Effect on Lithium Polysulfides for Lith-ium-Sulfur Batteries. Small, 14, Article ID: 1701986. https://doi.org/10.1002/smll.201701986

- 9. Ding, Z.W., Zhao, D.L., Yao, R.R., Li, C., Cheng, X.W. and Hu, T. (2018) Polyaniline@spherical Ordered Mesoporous Car-bon/Sulfur Nanocomposites for High-Performance Lithium-Sulfur Batteries. International Journal of Hydrogen Energy, 43, 10502-10510. https://doi.org/10.1016/j.ijhydene.2018.04.134

- 10. Liang, X.Q., Wang, J.J., Zhang, S.Y., Wang, L.Y., Wang, W.F., Li, L.Y., Wang, H.F., Huang, D., Zhou, W.Z. and Guo, J. (2019) Fabrication of Uniform Si-Incorporated SnO2 Nanoparticles on Graphene Sheets as Advanced Anode for Li-Ion Batteries. Applied Surface Sci-ence, 476, 28-35. https://doi.org/10.1016/j.apsusc.2018.12.288

- 11. Sun, W.W., Tao, X.C., Du, P.P. and Wang, Y. (2019) Carbon-Coated Mixed-Metal Sulfide Hierarchical Structure: MOF-Derived Synthesis and Lithium-Storage Per-formances. Chemical Engineering Journal, 366, 622-630. https://doi.org/10.1016/j.cej.2019.01.178

- 12. Lee, H., Yanilmaz, M., Toprakci, O., Fu, K. and Zhang, X. (2014) A Review of Recent Developments in Membrane Separators for Rechargeable Lithium-Ion Batteries. Energy & Environ-mental Science, 7, 3857-3886. https://doi.org/10.1039/C4EE01432D

- 13. Zhao, G.Y., Tang, L., Zhang, L., Chen, X., Mao, Y.C. and Sun, K.N. (2018) Well-Developed Capacitive-Capacity of Metal-Organic Framework Derived Co3O4 Films in Li Ion Battery An-odes. Journal of Alloys and Compounds, 746, 277-284. https://doi.org/10.1016/j.jallcom.2018.02.285

- 14. Li, N., Weng, Z., Wang, Y., Li, F., Cheng, H.-M. and Zhou, H. (2014) An Aqueous Dissolved Polysulfide Cathode for Lithi-um-Sulfur Batteries. Energy & Environmental Science, 7, 3307-3312. https://doi.org/10.1039/C4EE01717J

- 15. Zhang, L., Liang, P., Shu, H.B., Man, X.L., Li, F., Huang, J., Dong, Q.M. and Chao, D.L. (2017) Borophene as Efficient Sulfur Hosts for Lithium-Sulfur Batteries: Suppressing Shuttle Ef-fect and Improving Conductivity. The Journal of Physical Chemistry C, 121, 15549-15555. https://doi.org/10.1021/acs.jpcc.7b03741

- 16. Yan, B., Li, X., Bai, Z., Song, X., Xiong, D., Zhao, M., Li, D. and Lu, S. (2017) A Review of Atomic Layer Deposition Providing High Performance Lithium Sulfur Batteries. Journal of Power Sources, 338, 34-48. https://doi.org/10.1016/j.jpowsour.2016.10.097

- 17. Daniele, D.L., Roberta, V. and Jusef, H. (2017) Lithium-Ion Batteries for Sustainable Energy Storage: Recent Advances towards New Cell Configurations. Green Chemistry, 19, 3442-3467. https://doi.org/10.1039/C7GC01328K

- 18. He, Y.B., Chang, Z., Wu, S.C. and Zhou, H.S. (2018) Ef-fective Strategies for Long-Cycle Life Lithium-Sulfur Batteries. Journal of Materials Chemistry A, 6, 6155-6182. https://doi.org/10.1039/C8TA01115J

- 19. Han, Y., Dong, L., Feng, J., Li, D., Li, X. and Liu, S. (2015) Cobalt Oxide Modified Porous Carbon Anode Enhancing Electrochemical Performance for Li-Ion Batteries. Electrochimica Acta, 167, 246-253. https://doi.org/10.1016/j.electacta.2015.03.197

- 20. Wang, Y., Qu, Q., Han, Y., Gao, T., Shao, J., Zuo, Z., Liu, W., Shi, Q. and Zheng, H. (2016) Robust 3D Nanowebs Assembled from Interconnected and Sandwich-Like C@Fe3O4@C Coaxial Nanocables for Enhanced Li-Ion Storage. Journal of Materials Chemistry A, 4, 10314-10320. https://doi.org/10.1039/C6TA03118H

- 21. Ren, J., Ren, R.P. and Lv, Y.K. (2018) A Flexible 3D Gra-phene@CNT@MoS2 Hybrid Foam Anode for High-Performance Lithium-Ion Battery. Chemical Engineering Journal, 353, 419-424. https://doi.org/10.1016/j.cej.2018.07.139

- 22. Huang, Z.D., Liu, X.M., Oh, S.W., Zhang, B., Ma, P.C. and Kim, J.K. (2011) Microscopically Porous, Interconnected Single Crystal LiNi1/3Co1/3Mn1/3O2 Cathode Material for Lithium Ion Batteries. Journal of Materials Chemistry, 21, 10777-10784. https://doi.org/10.1039/c1jm00059d

- 23. Chen, R., Zhao, T., Lu, J.,Wu, F., Li, L., Chen, J., Tan, G., Ye, Y. and Amine, K. (2013) Graphene-Based Three-Dimensional Hi-erarchical Sandwich-Type Architecture for High-Performance Li/S Batteries. Nano Letters, 13, 4642-4649. https://doi.org/10.1021/nl4016683

- 24. Tian, X.H., Zhou, Y.K., Tu, X.F., Zhang, Z.T. and Du, G.D. (2017) Well-Dispersed LiFePO4 Nanoparticles Anchored on a Three-Dimensional Graphene Aerogel as High-Performance Pos-itive Electrode Materials for Lithium-Ion Batteries. Journal of Power Sources, 340, 40-50. https://doi.org/10.1016/j.jpowsour.2016.11.049

- 25. Yao, M., Okuno, K., Iwaki, T., Kato, M., Tanase, S., Emura, K. and Sakai, T. (2007) LiFePO4-Based Electrode Using Micro-Porous Current Collector for High Power Lithium Ion Battery. Journal of Power Sources, 173, 545-549. https://doi.org/10.1016/j.jpowsour.2007.08.014

- 26. Du, Y.H., Tang, Y.F., Huang, F.Q. and Chang, C.K. (2016) Preparation of Three-Dimensional Free-Standing Nano-LiFePO4/Graphene Composite for High Performance Lithium Ion Battery. RSC Advances, 6, 52279-52283. https://doi.org/10.1039/C6RA08937B

- 27. Fu, F., Tang, J.Y., Yao, Y.Z. and Shao, M.H. (2016) Hollow Porous Hierarchical-Structured 0.5Li2MnO¬-0.5LiMn0.4Co0.3Ni0.3O2 as a High-Performance Cathode Material for Lithium-Ion Batteries. ACS Applied Materials & Interfaces, 8, 25654-25659. https://doi.org/10.1021/acsami.6b09118

- 28. Xu, J.T., Chou, S.L., Zhou, C.F., Gu, Q.F., Liu, H.K. and Dou, S.X. (2014) Three-Dimensional-Network Li3V2(PO4)3/C Composite as High Rate Lithium Ion Battery Cathode Material and Its Compatibility with Ionic Liquid Electrolytes. Journal of Power Sources, 246, 124-131. https://doi.org/10.1016/j.jpowsour.2013.07.055

- 29. Cui, K. and Li, Y.K. (2016) Monoclinic Li3V2(PO4)3/C Nanocrystals Co-Modified with Graphene Nanosheets and Carbon Nanotubes as a Three-Dimensional-Network Cathode Material for Rechargeable Lithium-Ion Batteries. RSC Advances, 6, 8431-8439. https://doi.org/10.1039/C5RA22005J

- 30. Chao, D., Xia, X., Liu, J., Fan, Z., Ng, C.F., Lin, J., Zhang, H., Shen, Z.X. and Fan, H.J. (2014) Lithium-Ion Batteries: A V2O5/Conductive-Polymer Core/Shell Nanobelt Array on Three-Dimensional Graphite Foam: A High-Rate, Ultrastable, and Freestanding Cathode for Lithium-Ion Batteries. Ad-vanced Materials, 26, 5733. https://doi.org/10.1002/adma.201470223

- 31. Gao, X.T., Liu, Y.T., Zhu, X.D., Yan, D.J., Wang, C., Feng, Y.J. and Sun, K.N. (2018) V2O5 Nanoparticles Confined in Three-Dimensionally Organized, Porous Nitrogen-Doped Gra-phene Frameworks: Flexible and Free-Standing Cathodes for High Performance Lithium Storage. Carbon, 140, 218-226. https://doi.org/10.1016/j.carbon.2018.08.060

- 32. Pan, A.Q., Wu, H.B., Yu, L., Zhu, T. and Lou, X.W. (2012) Synthesis of Hierarchical Three-Dimensional Vanadium Oxide Microstructures as High-Capacity Cathode Materials for Lithium-Ion Batteries. ACS Applied Materials & Interfaces, 4, 3874-3879. https://doi.org/10.1021/am3012593

- 33. Guo, Q., Sun, Z., Gao, M., Tan, Z., Zhang, B. and Su, D.S. (2013) Po-rous V2O5-SnO2/CNTs Composites as High-Performance Cathode Materials for Lithium-Ion Batteries. Journal of Ener-gy Chemistry, 22, 347-355. https://doi.org/10.1016/S2095-4956(13)60043-1

- 34. Liu, J., Zheng, Q., Goodman, M.D., Zhu, H., Kim, J., Krue-ger, N.A., Ning, H., Huang, X., Liu, J., Terrones, M. and Braun, P.V. (2016) Graphene Sandwiched Mesostructured Li-Ion Battery Electrodes. Advanced Materials, 28, 7696-7702. https://doi.org/10.1002/adma.201600829

- 35. Park, B.G., Kim, S., Kim, I.-D. and Park, Y.J. (2010) Structural and Electrochemical Performance of Three-Dimensional LiMn2O4 Thin Film. Journal of Materials Science, 45, 3947-3953. https://doi.org/10.1007/s10853-010-4460-1

- 36. Zhang, X.H., Chen, D., Liu, Y.P., Han, W.W., Chu, H.Q. and Rui, X.H. (2017) Integrated Charge Transfer in Li3V2(PO4)3/C for High-Power Li-Ion Batteries. International Journal of Electrochemical Science, 12, 9925-9932. https://doi.org/10.20964/2017.11.26

- 37. Li, J.Z., Luo, S.H., Ding, X.Y., Wang, Q. and He, P. (2018) Three-Dimensional Honeycomb-Structural LiAlO2-Modified LiMnPO4 Composite with Superior High Rate Capacity as Li-Ion Battery. ACS Applied Materials & Interfaces, 10, 10786-10795. https://doi.org/10.1021/acsami.7b17597

- 38. Ragupathi, V., Krishnaswamy, S., Raman, S., Panigrahi, P., Lee, J. and Nagarajan, G.S. (2018) Enhanced Electrochemical Performance of LiCoBO3 Cathode Material for Next Generation Lithium-Ion Batteries. Applied Surface Science, 449, 421-425. https://doi.org/10.1016/j.apsusc.2017.11.087

- 39. Wang, Y., Shao, X., Xu, H., Xie, M., Deng, S., Wang, H., Liu, J. and Yan, H. (2013) Facile Synthesis of Porous LiMn2O4 Spheres as Cathode Materials for High-Power Lithium Ion Batteries. Journal of Power Sources, 226, 140-148. https://doi.org/10.1016/j.jpowsour.2012.10.077

- 40. Huang, Y., Hou, X., Ma, S., Zou, X., Wu, Y., Hu, S., Shao, Z. and Liu, X. (2015) Template GNL-Assisted Synthesis of Porous Li1.2Mn0.534Ni0.133Co0.133O2: Towards High Performance Cathodes for Lithium Ion Batteries. RSC Advances, 5, 25258-25265. https://doi.org/10.1039/C5RA00845J

- 41. Biasi, L.D., Lieser, G., Drager, C., Indris, S., Rana, J., Schumacher, G., Monig, R., Ehrenberg, H., Binder, J.R. and Gebwein, H. (2017) LiCaFeF6: A Zero-Strain Cathode Ma-terial for Use in Li-Ion Batteries. Journal of Power Sources, 362, 192-201. https://doi.org/10.1016/j.jpowsour.2017.07.007

- 42. Baster, D., Paziak, P., Ziabka, M., Wazny, G. and Molenda, J. (2018) LiNi0.6Co0.4-zTizO2—New Cathode Materials for Li-Ion Batteries. Solid State Ionics, 320, 118-125. https://doi.org/10.1016/j.ssi.2018.03.002

- 43. Doherty, C.M., Caruso, R.A., Smarsly, B.M. and Drummond, C.J. (2009) Colloidal Crystal Templating to Produce Hierarchically Porous LiFePO4 Electrode Materials for High Power Lithium Ion Batteries. Chemistry of Materials, 21, 2895-2903. https://doi.org/10.1021/cm900698p

- 44. Tu, X., Zhou, Y. and Song, Y. (2017) Freeze-Drying Synthesis of Three-Dimensional Porous LiFePO4 Modified with Well-Dispersed Nitrogen-Doped Carbon Nanotubes for High-Performance Lithium-Ion Batteries. Applied Surface Sci-ence, 400, 329-338. https://doi.org/10.1016/j.apsusc.2016.12.220

- 45. Zhao, H.Y., Wang, J., Wang, G.F., Liu, S.S., Tan, M., Liu, X.Q. and Komarneni, S. (2017) Facile Synthesis of Orthorhombic LiMnO2 Nanorods by In-Situ Car-bothermal Reduction: Promising Cathode Material for Li Ion Batteries. Ceramics International, 43, 10585-10589. https://doi.org/10.1016/j.ceramint.2017.04.158

- 46. Duan, L., Zhang, X., Yue, K., Wu, Y., Zhuang, J. and Lu, W. (2017) Synthesis and Electrochemical Property of LiMn2O4 Porous Hollow Nanofiber as Cathode for Lithium-Ion Bat-teries. Nanoscale Research Letters, 12, 109. https://doi.org/10.1186/s11671-017-1879-1

- 47. Jing, M.X., Pi, Z.C., Zhai, H.A., Li, J.Q., Chen, L.L., Shen, S.Q., Xi, X.M. and Xiao, K.S. (2016) Three-Dimensional Li3V2(PO4)3/C Nanowire and Nanofiber Hybrid Membrane as a Self-Standing, Binder-Free Cathode for Lithium Ion Batteries. RSC Advances, 6, 71574-71580. https://doi.org/10.1039/C6RA13686A

- 48. Li, Y.H., Xiang, K.X., Shi, C.F., Zhou,W., Zhu, Y.R. and Chen, H. (2017) Frogegg-Like Li3V2(PO4)3/Carbon Composite with Three Dimensional Porous Structure and Its Improved Elec-trochemical Performance in Lithium Ion Batteries. Materials Letters, 204, 104-107. https://doi.org/10.1016/j.matlet.2017.05.098

- 49. Zhu, H., Wu, X.Z., Zan, L. and Zhang, Y.X. (2014) Three-Dimensional Macroporous Graphene-Li2FeSiO4 Composite as Cathode Material for Lithium-Ion Batteries with Superior Electrochemical Performances. ACS Applied Materials & Interfaces, 6, 11724-11733. https://doi.org/10.1021/am502408m

- 50. Bao, Y.H., Zhang, X.Y., Zhang, X., Yang, L., Zhang, X.Y., Chen, H.S., Yang, M. and Fang, D.N. (2016) Free-Standing and Flexible LiMnTiO4/Carbon Nanotube Cathodes for High Perfor-mance Lithium Ion Batteries. Journal of Power Sources, 321, 120-125. https://doi.org/10.1016/j.jpowsour.2016.04.121

- 51. Tang, C., Li, B.Q., Zhang, Q., Zhu, L., Wang, H.F., Shi, J.L. and Wei, F. (2016) CaO-Templated Growth of Hierarchical Porous Graphene for High-Power Lithium-Sulfur Battery Applications. Advanced Functional Materials, 26, 577-585. https://doi.org/10.1002/adfm.201503726

- 52. Su, D.W., Cortie, M. and Wang, G.X. (2017) Fabrication of N-Doped Graphene-Carbon Nanotube Hybrids from Prussian Blue for Lithium-Sulfur Batteries. Advanced Energy Materials, 7, Article ID: 1602014. https://doi.org/10.1002/aenm.201602014

- 53. Ummethala, R., Fritzsche, M., Jaumann, T., Balach, J., Oswald, S., Nowak, R., Sobczak, N., Kaban, I., Rümmeli, M.H. and Giebeler, L. (2018) Lightweight, Free-Standing 3D Intercon-nected Carbon Nanotube foam as a Flexible Sulfur Host for High Performance Lithium-Sulfur Battery Cathodes. Energy Storage Materials, 10, 206-215. https://doi.org/10.1016/j.ensm.2017.04.004

- 54. Lu, S., Chen, Y., Wu, X., Wang, Z. and Li, Y. (2014) Three-Dimensional Sulfur/Graphene Multifunctional Hybrid Sponges for Lithium-Sulfur Batteries with Large Areal Mass Loading. Scientific Reports, 4, Article No. 4629. https://doi.org/10.1038/srep04629

- 55. Li, H.P., Wei, Y.Q., Ren, J., Zhang, W.L., Zhang, C.W. and Zhang, Y.G. (2018) Three-Dimensionally Ordered Hierarchically Porous Polypyrrole Loading Sulfur as High-Performance Cathode for Lithium/Sulfur Batteries. Polymer, 137, 261-268. https://doi.org/10.1016/j.polymer.2018.01.022

- 56. Li, C.X., Yu, J.Y., Xue, S.L., Cheng, Z.H., Sun, G.Q., Zhang, J., Huang, R.D. and Qu, L.T. (2018) Wood-Inspired Mul-ti-Channel Tubular Graphene Network for High-Performance Lithium-Sulfur Batteries. Carbon, 139, 522-530. https://doi.org/10.1016/j.carbon.2018.07.023

- 57. Gu, X.X., Tong, C.J., Wen, B., Liu, L.M., Lai, C. and Zhang, S.Q. (2016) Ball-Milling Synthesis of ZnO@sulphur/Carbon Nanotubes and Ni(OH)2@sulphur/Carbon Nanotubes Composites for High-Performance Lithium-Sulphur Batteries. Electrochimica Acta, 196, 369-376. https://doi.org/10.1016/j.electacta.2016.03.018

- 58. Li, Z., Zhang, S.G., Zhang, J.H., Xu, M., Tatara, R., Dokko, K. and Watanabe, M. (2017) Three-Dimensionally Hierarchical Ni/Ni3S2/S Cathode for Lithium-Sulfur Battery. ACS Applied Materials & Interfaces, 9, 38477-38485. https://doi.org/10.1021/acsami.7b11065

- 59. Song, Y.Z., Zhao, W., Kong, L., Zhang, L., Zhu, X.Y., Shao, Y.L., Ding, F., Zhang, Q., Sun, J.Y. and Liu, Z.F. (2018) Synchronous Immobilization and Conversion of Polysulfides on a VO2-VN Binary Host Targeting High Sulfur Load Li-S Batteries. Energy & Environmental Science, 11, 2620-2630. https://doi.org/10.1039/C8EE01402G

- 60. Daniel, P., Tabor, L.M.R., Semion, K.S., Christoph, K., Dennis, S., Jo-seph, H.M., Shyam, D., Muratahan, A., Carlos, O., Hermann, T., et al. (2018) Accelerating the Discovery of Materials for Clean Energy in the Era of Smart Automation. Nature Reviews Materials, 3, 5-20. https://doi.org/10.1038/s41578-018-0005-z

- 61. Garg, A., Peng, X.B., Le, M.L.P., Pareek, K. and Chind, C.M.M. (2018) Design and Analysis of Capacity Models for Lithium-Ion Battery. Measurement, 120, 114-120. https://doi.org/10.1016/j.measurement.2018.02.003

- 62. Li, J., Zou, L.L., Tian, F., Dong, X.W., Zou, Z.Q. and Yang, H. (2016) Parameter Identification of Lithium-Ion Batteries Model to Predict Discharge Behaviors Using Heuristic Algorithm. Journal of the Electrochemical Society, 163, A1646-A1652. https://doi.org/10.1149/2.0861608jes

- 63. Garg, A., Vijayaraghavan, V., Zhang, J., Li, S. and Liang, X.Y. (2017) Design of Robust Battery Capacity Model for Electric Vehicle by Incorporation of Uncertainties. International Journal of Energy Research, 41, 1436-1451. https://doi.org/10.1002/er.3723

NOTES

*通讯作者。