Material Sciences

Vol.08 No.05(2018), Article ID:25119,9

pages

10.12677/MS.2018.85067

The Influence of Oxygen Pressure on the Structure, Optoelectronic Properties, and MIT Characters of VO2 Thin Films

Xin Tao, Hao Lu, Pai Li, Yinmei Lu*, Yunbin He

Ministry-of-Education Key Laboratory of the Green Preparation and Application for Functional Materials, School of Materials Science and Engineering, Hubei University, Wuhan Hubei

Received: May 4th, 2018; accepted: May 20th, 2018; published: May 28th, 2018

ABSTRACT

Vanadium dioxide (VO2) epitaxial films were grown on TiO2 (110) substrates with various O2 pressures by pulsed laser deposition using a metal vanadium as target and high-purity O2 as reaction gas. The growth experiments were carried out at a fixed substrate temperature of 600˚C and different O2 pressures. X-ray diffraction (XRD), X-ray photoelectron spectroscopy (XPS), UV-visible-near-infrared spectrophotometer (UV-VIS-NIR) and four-probe method were used to characterize the films. The XRD rocking curve half widths at (011)-plane of the VO2 films deposited at various oxygen pressures are all very small, in the range of 0.12˚ - 0.27˚, indicating a very good out-of-plane atomic ordering of the films. It was revealed that 6.5 Pa was the optimum oxygen pressure for the growth of high-quality VO2 films, which exhibit a XRD rocking curve half width as small as 0.116˚, the most effective modulation to solar energy in the visible-near-infrared region, and almost four orders of magnitude change in resistance, i.e., an obvious metal-insulator transition character at a temperature around 63˚C.

Keywords:VO2 Film, Metal-Insulator Transition (MIT), Pulsed Laser Deposition (PLD)

沉积氧压对二氧化钒薄膜结构、光电性能及其MIT相变特性的影响研究

陶欣,陆浩,李派,卢寅梅*,何云斌

湖北大学材料科学与工程学院,功能材料绿色制备与应用教育部重点实验室(湖北大学),湖北 武汉

收稿日期:2018年5月4日;录用日期:2018年5月20日;发布日期:2018年5月28日

摘 要

本工作中我们采用脉冲激光沉积法,以金属钒靶作为烧蚀靶材、高纯氧气作为反应气体,通过改变薄膜生长时的氧压,在TiO2 (110)衬底上制备VO2薄膜。利用X射线衍射仪、X射线光电子能谱分析仪、紫外-可见-近红外光谱测试仪、四探针测试仪系统测试并研究了薄膜生长氧压对VO2薄膜的结构、成分、光学性能及金属-绝缘体相变特性的影响。实验结果表明:不同氧压下制备的VO2薄膜(011)晶面X射线衍射摇摆曲线半高宽都很小(在0.12˚~0.27˚范围),表明薄膜的面外取向度很高;当氧压为6.5 Pa时,制备的VO2薄膜摇摆曲线半高宽最小(0.116˚),相变前后薄膜对太阳能调制最大、其电阻开关比达到4个数量级,薄膜相变温度接近63℃,金属-绝缘体转变特性显著。

关键词 :VO2薄膜,金属-绝缘体相变,脉冲激光沉积法

Copyright © 2018 by authors and Hans Publishers Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

1. 引言

1959年Morin [1] 发现二氧化钒(VO2)具有由低温绝缘相到高温金属相的可逆相变特性,且其相变温度为68℃ [2] ,稍高于室温。人们通过掺杂不同元素和改变生长条件来调节二氧化钒的相变温度,使其进一步降低到室温附近。在二氧化钒发生相变后,其由单斜结构的绝缘体相转变为金红石结构的金属相,电阻率有4到5个数量级的变化 [3] [4] 。二氧化钒相变前后对红外光的透过有着很大的改变,且其相变前后的光电磁特性变化都是可逆的。由于这些可逆的特性,二氧化钒在光电开关、红外探测器、智能玻璃等方面具有良好的应用前景 [5] [6] [7] [8] 。

氧空位和应力对VO2的相变特性具有显著的影响 [9] 。由于钒具有多种价态,易形成V2O3、VO2、V2O5等氧化物,所以生长氧压对纯相二氧化钒的制备至关重要。过去已有多种方法用于VO2薄膜的制备,基于反应介质主要可分为气相沉积法和液相沉积法两大类。气相沉积法又可分为化学气相沉积(CVD: Chemical Vapor Deposition) [10] [11] 和物理气相沉积 [12] [13] [14] [15] (PVD: Physical Vapor Deposition)两种。化学气相沉积法的成膜装置简单,适用于形状复杂的零件和内孔镀膜,但其沉积速率不高,对环境有污染,对设备耐腐蚀性能有一定要求;而物理气相沉积法的技术工艺过程简单,对环境无污染、耗材少,成膜均匀致密、与基体的结合强。脉冲激光沉积(PLD: Pulsed Laser Deposition)法因沉积速率高,制备的薄膜均匀,易获得符合化学计量比的多组分膜而被公认为实验室制备薄膜的最好方法之一。在1993年Singh [16] 等人最先用PLD法在R面蓝宝石上制备了VO2薄膜。

在本工作中,我们采用脉冲激光沉积法,以金属钒靶作为烧蚀靶材、TiO2 (110)作为衬底、高纯氧气作为反应气体,固定衬底温度600℃和沉积时间30 min,通过改变氧压大小制备出系列VO2薄膜,以探究沉积氧压对薄膜结构及其金属-绝缘体相变(MIT: Metal-Insulator Transition)特性的影响。

2. 实验

2.1. 薄膜样品制备

本实验中,我们采用PLD方法,以金属钒(V)靶作为烧蚀靶材,采用单晶TiO2 (110)作为衬底、高纯氧气O2 (99.999%)作为反应气体,通过调节生长氧压大小来制备VO2薄膜。实验中使用的是德国Lambda Physik公司生产的KrF准分子激光器(COMPEX PRO 205F),输出波长为248 nm,固定激光频率为5 Hz,激光脉冲能量为420 mJ/Pulse。沉积薄膜之前,首先将TiO2 (110)衬底放入真空管式炉中在空气中、900℃下退火1小时,以消除衬底中的应力及表面吸附杂质,使其更有利于高质量VO2薄膜的外延生长。然后,将衬底依次在丙酮、乙醇、去离子水中超声清洗各15 min,以进一步去除表面污染物杂质。清洗干净的衬底用氮气吹干后固定于样品托上,并被立即送入PLD真空室内。固定靶材和衬底之间的距离为55 mm,待真空室压强抽至4.0 × 10−4 Pa以下,开始加热衬底至薄膜生长所需温度(600℃),随后通入高纯氧气,设置靶材和衬底分别以5 r/min和10 r/min的速度转动,开启激光器沉积薄膜30 min。薄膜生长完毕后,待样品在真空室自然冷却至室温后取出。设定沉积时的氧压分别为4.5 Pa、5.5 Pa、6.0 Pa、6.5 Pa、7.0 Pa、7.5 Pa,得到6个不同氧压下生长的薄膜样品。

2.2. 薄膜样品测试

通过场发射扫描电镜(FE-SEM, 蔡司(ZEISS), SIGMA 500)观测薄膜断面,可知薄膜厚度大约为60 nm;采用四圆单晶X射线衍射仪(HRXRD, D8 discover, Bruker, CuKα1, λ = 1.540598 Å)对薄膜的晶体结构进行分析,使用X射线光电子能谱分析仪(XPS, Escalab 250Xi, Thermo Scientific)对薄膜的成分进行检测,采用UV3600Plus型紫外-可见-近红外光谱仪测试其对可见-近红外光的透过率,通过四探针法来测量薄膜在升温和降温过程中电阻的变化。

3. 结果与讨论

3.1. 沉积氧压对薄膜晶体结构的影响

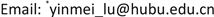

图1(a)、图1(b)分别为不同氧压下生长的VO2薄膜XRD全谱图和窄谱图。从全谱图中可以看出,27.44˚和56.64˚分别对应于TiO2 (110)衬底的(110)和(220)面衍射峰,28.2˚和57.16˚分别对应单斜相M-VO2的(011)

Figure 1. The θ-2θ scan XRD patterns of VO2 films grown at different oxygen pressures: (a) broad-scan; (b) narrow-scan

图1. 不同氧压下生长VO2薄膜的θ-2θ扫描XRD图谱:(a) 全谱图;(b) 窄谱图

和(022)面衍射峰。当沉积氧压为4.5 Pa时,除了衬底的衍射峰外,图谱中出现了金红石相R-VO2 (110)的衍射峰和单斜相M-VO2 (011)的衍射峰;沉积氧压在5.5 Pa与6.0 Pa之间时,除了衬底的衍射峰外,只出现了单斜相VO2的衍射峰,表明成功得到单相的M-VO2薄膜;当沉积氧压 ≥ 6.5 Pa时,除了衬底和M-VO2的衍射峰外,谱图在45.34˚处出现微弱的V2O5 (411)的杂峰,表明此条件下制备的VO2薄膜中含有微量的V2O5相。从窄谱图中可以看出,随着氧压从5.5 Pa升高到7.0 Pa,VO2 (011)面衍射峰从28.124˚逐渐向低角度移动到27.98˚,此峰位移动是由于随着沉积氧压升高VO2薄膜中氧空位减少造成的 [17] 。由布拉格方程2dsinθ = nλ (d为衍射晶面间距,θ为入射X射线与晶面的夹角,λ为X射线波长,n为衍射级数通常取1)可以计算出,对应于VO2 (011)面衍射峰从28.124˚移动到27.98˚,薄膜面间距从3.1703 Å增加到3.1863 Å,如表1所示。为了研究薄膜的面外取向度,对不同氧压下生长的VO2薄膜的摇摆曲线进行测试,结果如图2所示。从图中可以看出,实验得到的薄膜的摇摆曲线半高宽都很小(在0.12˚~0.27˚范围),表明薄膜的面外取向高、结晶质量好。

Figure 2. The XRD rocking curves of the (011)-plane of VO2 films

图2. VO2薄膜(011)面的摇摆曲线图

Table 1. Metal-insulator phase transition temperature and (011)-plane interlayer spacing of VO2 films deposited at different oxygen pressures.

表1. 不同氧压下生长VO2薄膜的金属-绝缘体相变温度及(011)晶面的面间距

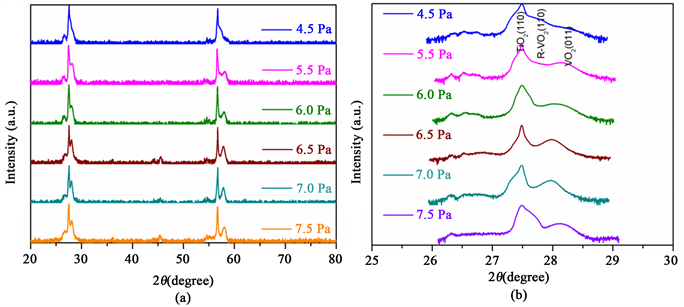

3.2. 沉积氧压对薄膜成分的影响

图3展示了6.5 Pa、7.5 Pa下生长的VO2薄膜的XPS全谱图,从图中可以看出,除了V、O特征峰外,还有C的特征峰被测到,这是由于薄膜长时间暴露在空气中,碳氢化合物杂质吸附在薄膜的表面所造成的,所生长的薄膜中没有引入其它杂质元素。

3.3. 沉积氧压对薄膜光学性能的影响

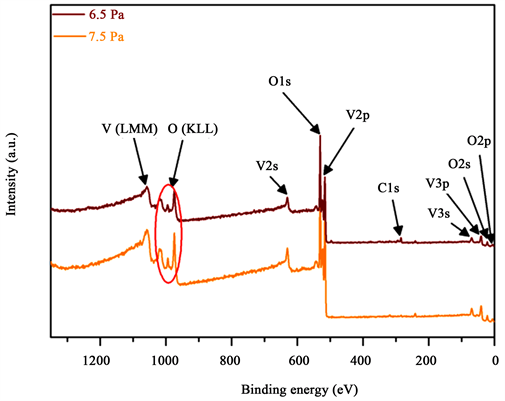

图4展示的是不同氧压下生长的VO2薄膜的可见-红外光的透射光谱图及透射光谱相关数据分析结果图。图4(a)中的实线代表的是不同氧压下生长的VO2薄膜在环境温度为25℃时的透过率,虚线代表的是在90℃的透过率(l为透射光波的波长,其范围为400 nm ≤ λ ≤ 2500 nm)。由图可见,对于可见光(400~800 nm),VO2薄膜在高温和低温下的透过率几乎相等,而对于近红外光(800~2500 nm),VO2薄膜在高温和低温下的透过率相差很大,即:VO2薄膜在相变前后对近红外光透过率具有明显调制作用。图4(b)中的数据表明,当温度为25℃,VO2薄膜对波长为2500 nm的红外光的透过率随氧压变化不大,基本都达到了65%;当温度为90℃时,VO2薄膜对波长为2500 nm的红外光的透过率随氧压的增加先减小后增大,在7.0 Pa时,达到最小值8%,与此对应,VO2薄膜在相变前后对2500 nm波长红外光透过率的调制幅度(ΔT = T25°C − T90°C)随氧压增加先增大后减小,在7.0 Pa时,到达最大值60%。对于VO2薄膜在智能窗玻璃涂层上的应用,其相变前后对于太阳光谱中可见光(410~800 nm)透过率的影响及可见-近红外波段(410~2500 nm)能量透过率的调制幅度至关重要。图4(c)、图4(d)分别给出本工作制备的VO2薄膜在25℃和90℃下对太阳光谱中可见光波段与可见-近红外波段辐照能量透过率Tvis、Tsol及相变前后透过率的差值ΔTvis、ΔTsol。太阳光谱辐照能量透过率T根据积分公式 [18] :

Figure 3. The XPS survey spectra of VO2 films prepared at 6.5 Pa and 7.5 Pa oxygen pressure

图3. 6.5 Pa、7.5 Pa氧压下制备的VO2薄膜的XPS全谱

Figure 4. The visible-near infrared transmittance curves of VO2 thin films prepared under different oxygen pressures: (a) transmittance spectra in the visible near infrared region measured at 25˚C and 90˚C (i.e., before and after the phase transition of VO2); (b) transmittance at fixed infrared light wavelength of 2500 nm; (c) transmittance in the visible light region (410 nm £ l £ 780 nm); and (d) transmittance in the visible-near infrared region (410 nm £ l £ 2500 nm) before and after the phase transition of VO2 thin films

图4. 不同氧压下制备的VO2薄膜对可见-近红外光的透过率曲线图谱:(a) 薄膜在低温25℃和高温90℃下(即相变前后)对可见-近红外光透射全谱图;(b) 薄膜在相变前后对固定波长2500 nm红外光的透过率T2500 nm, 25℃、T2500 nm, 90℃及其差值ΔT2500 nm;(c) 薄膜在相变前后对可见波段(410~800 nm)光的透过率Tvis, 25℃、Tvis, 90℃及其差值△Tvis;(d) 薄膜在相变前后对可见-近红外波段(410~2500 nm)光的透过率Tsol, 25℃、Tsol, 90℃及其差值△Tsol

计算所得,其中T(l)为不同波长光的透过率,E(l)在可见光情形(图4(c))运用人眼的光谱灵敏度 [19] ,在可见-近红外波段(图4(d))运用太阳光谱辐照度 [20] 。从图中可以看出:相变前后的VO2薄膜对于可见光的透过率(图4(c))均随着生长氧压的增加先增加再减小最后又增加,不过相变前后对可见光调控幅度小于4%,且随氧压增加呈现变小的趋势。相比较而言,VO2薄膜在相变前后对可见-近红外波段太阳能的调控(图4(d))作用明显,其调控幅度随着氧压的增大先增大后减小,在氧压为6.5 Pa时达到最大值~12%。

3.4. 沉积氧压对薄膜MIT相变的影响

利用四探针法测量不同氧压下生长的VO2薄膜电阻随温度的变化关系。对升温和降温过程中电阻变化进行分别测量,结果如图5所示。当氧压从4.5 Pa增加到6.5 Pa时,薄膜相变前后电阻的开关比由1个数量级逐步增大到接近4个数量级;随着氧压继续增大到7.5 Pa时,开关比又逐渐减小,直至基本消失,由此可以说明生长氧压能显著改变薄膜MIT相变前后电阻开关比。这是因为当氧压过低时,制备的VO2薄膜中有很多氧空位;而当氧压过高时,制备的VO2薄膜中含有V2O5杂相,这在XRD θ-2θ全谱图中可以看出。相变前后VO2薄膜电阻开关比与薄膜对太阳能调控随氧压的变化趋势相同,都随氧压的增大先增大后减小,在氧压为6.0 Pa~6.5 Pa时达到最大。

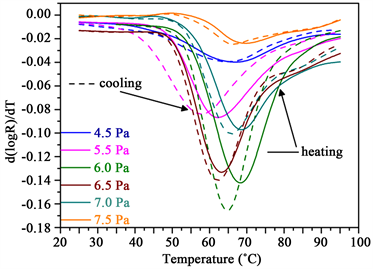

为了获得VO2薄膜MIT相变温度,我们对变温电阻曲线进行了微分处理,结果如图6所示。随着氧压的增大,薄膜变温电阻微分曲线先由平缓逐渐变得陡峭,随着氧压继续增大,薄膜变温电阻微分曲线又变得平缓。升温、降温过程电阻微分曲线的拐点分别记为Tc,heating、Tc,cooling,则薄膜相变温度Tc可由公式Tc = (Tc,heating + Tc,cooling)/2计算确定,结果如表1所示。随着氧压在4.5 Pa~7.5 Pa之间变化,VO2薄膜MIT相变温度在60℃~68℃之间变化,与VO2体材的相变温度(68℃)接近。不同沉积氧压使得薄膜中存在不同浓度的氧空位,氧空位可以有效调节薄膜的相变温度。

4. 结论

本工作通过脉冲激光沉积法在TiO2 (110)衬底上生长VO2薄膜,研究了沉积氧压对VO2薄膜结晶性、光电特性的影响。氧压过高容易生成钒的其他氧化物杂相,氧压过低导致薄膜中存在大量氧空位而使薄膜MIT特性表现不明显。VO2薄膜生长的最佳氧压为6.5 Pa,此条件下制备薄膜的(011)面XRD摇摆曲线半高宽降至0.116˚,UV测试结果表明薄膜对可见光和太阳能的调控均达到最佳,薄膜相变前后电阻的开关比达到近4个数量级。当沉积氧压在5.5 Pa至7.0 Pa之间时,薄膜都显示出明显的MIT特性,相变温度在60℃~68℃之间变化,这表明薄膜中氧空位浓度可以有效调节VO2 MIT相变温度。

Figure 5. The temperature-dependent resistance of VO2 films prepared under different oxygen pressures. Solid and dashed lines represent the heating and cooling processes, respectively

图5. 不同氧压下制备的VO2薄膜的变温电阻曲线(实线和虚线分别代表升温和和降温过程)

Figure 6. The temperature-dependent differential resistance of VO2 films prepared under different oxygen pressures

图6. 不同氧压下制备的VO2薄膜的变温电阻微分曲线

致谢

感谢国家自然科学基金(61274010, 11574074, 11774082);湖北省自然科学基金(2016AAA031);武汉国际科技合作项目(2016030409020222)以及材料复合新技术国家重点实验室(武汉理工大学)开放基金(2018-KF-16)对本工作的支持。

文章引用

陶 欣,陆 浩,李 派,卢寅梅,何云斌. 沉积氧压对二氧化钒薄膜结构、光电性能及其MIT相变特性的影响研究

The Influence of Oxygen Pressure on the Structure, Optoelectronic Properties, and MIT Characters of VO2 Thin Films[J]. 材料科学, 2018, 08(05): 573-581. https://doi.org/10.12677/MS.2018.85067

参考文献

- 1. Morin, F.J. (1959) Oxides Which Show a Metal to Insulator Transition at Neel Temperature. Physical Review Letters, 3, 34-36.

https://doi.org/10.1103/PhysRevLett.3.34 - 2. Leroux, C., Nihoul, G. and Van Tendeloo, G. (1998) From VO2(B) to VO2(R): Theoretical Structures of VO2 Polymorphs and in Situ Electron Microscopy. Physical Review B, 57, 5111-5121.

https://doi.org/10.1103/PhysRevB.57.5111 - 3. Yang, T.H., Mal, S., Jin, C., et al. (2011) Epitaxial VO2/Cr2O3/Sapphire Heterostructure for Multifunctional Applications. Applied Physics Letters, 98, 022105.

https://doi.org/10.1063/1.3541649 - 4. Zhang, H., Wu, Z., Yang, W., et al. (2013) Large Phase-Transition Hysteresis for Nanostructured VOx Film Prepared on ITO Conductive Glass by DC Reactive Magnetron Sputtering. Vacuum, 98, 84-86.

https://doi.org/10.1016/j.vacuum.2013.01.027 - 5. Narayan, J. and Bhosle, V.M. (2006) Phase Transition and Critical Issues in Structure-Property Correlations of Vanadium Oxide. Journal of Applied Physics, 100, 1-3.

https://doi.org/10.1063/1.2384798 - 6. Jin, P., Yoshimura, K. and Tanemura, S. (1997) Dependence of Microstructure and Thermochromism on Substrate Temperature for Sputter-Deposited VO2 Epitaxial Films. Journal of Vacuum Science & Technology A, 15, 1113-1117.

https://doi.org/10.1116/1.580439 - 7. Kang, L.T., Gao, Y.F., Zhang, Z.T., Du, J., Cao, C.X., Chen, Z. and Luo, H.J. (2010) Effects of Annealing Parameters on Optical Properties of Thermochromic VO2 Films Prepared in Aqueous Solution. Journal of Physical Chemistry C, 114, 1901-1911.

https://doi.org/10.1021/jp909009w - 8. Li, S.Y., Niklasson, G.A. and Granqvist, C.G. (2012) Thermochromic Fenestration with VO2-Based Materials: Three Challenges and How They Can Be Met. Thin Solid Films, 520, 3823-3828.

https://doi.org/10.1016/j.tsf.2011.10.053 - 9. Kim, H., Charipar, N., Osofaky, M., et al. (2014) Optimization of the Semiconductor-Metal Transition in VO2 Epitaxial Thin Films as a Function of Oxygen Growth Pressure. Applied Physics Letters, 104, Article ID: 081913.

https://doi.org/10.1063/1.4866806 - 10. Wilkinson, M., Kafizas, A., Bawaked, S.M., Obaid, A.Y., Al-Thabaiti, S.A., Basahel, S.N., et al. (2013) Combinatorial Atmospheric Pressure Chemical Vapor Deposition of Graded TiO2-VO2 Mixed-Phase Composites and Their Dual Functional Property as Self-Cleaning and Photochromic Window Coatings. Acs Combinatorial Science, 15, 309-319.

https://doi.org/10.1021/co400027p - 11. Crane, J., Warwick, M., Smith, R., Furlan, N. and Binions, R. (2011) The Application of Electric Fields to Aerosol Assisted Chemical Vapor Deposition Reactions. Journal of the Electrochemical Society, 158, D62-D67.

https://doi.org/10.1149/1.3519870 - 12. Fuls, E.N., Hensler, D.H. and Ross, A.R. (1967) Reactively Sputtered Vanadium Dioxide Thin Films. Applied Physics Letters, 10, 199-201.

https://doi.org/10.1063/1.1754909 - 13. Kana, J.B.K., Ndjaka, J.M., Ngom, B.D., Manyala, N., Nemraoui, O., Fasasi, A.Y., et al. (2010) Thermochromic Nanocrystalline Au-VO2 Composite Thin Films Prepared by Radiofrequency Inverted Cylindrical Magnetron Sputtering. Thin Solid Films, 518, 1641-1647.

https://doi.org/10.1016/j.tsf.2009.11.074 - 14. Batista, C., Carneiro, J., Ribeiro, R.M. and Teixeira, V. (2011) Reactive Pulsed-DC Sputtered Nb-Doped VO2 Coatings for Smart Thermochromic Windows with Active Solar Control. Journal of Nanoscience and Nanotechnology, 11, 9042-9045.

https://doi.org/10.1166/jnn.2011.3486 - 15. Fortier, J.P., Baloukas, B., Zabeida, O., Klemberg-Sapieha, J.E. and Martinu, L. (2014) Thermochromic VO2 Thin Films Deposited by HiPIMS. Solar Energy Materials and Solar Cells, 125, 291-296.

https://doi.org/10.1016/j.solmat.2014.03.007 - 16. Borek, M., Qian, F., Nagabushnman, V., et al. (1993) Pulsed-Laser Deposition of Oriented VO2 Thin Films on R-Cut Sapphire Substrates. Applied Physics Letters, 63, 3288-3290.

- 17. Soltani, M., Chaker, M., Haddad, E., et al. (2007) Micro-Optical Switch Device Based on Semiconductor-to-Metallic Phase Transition Characteristics of W-Doped VO2 Smart Coatings. Journal of Vacuum Science & Technology A, 25, 971-975.

https://doi.org/10.1116/1.2734150 - 18. Babulanam, S.M., Eriksson, T.S., Niklasson, G.A. and Granqvist, C.G. (1987) Thermochromic VO2 Films for Energy-Efficient Windows. Solar Energy Materials, 6, 347-363.

https://doi.org/10.1016/0165-1633(87)90029-3 - 19. DIN 5031-1:1982-03 Strahlungsphysik im optischen Bereich und Lichttechnik; Größen, Formelzeichen und Einheiten der Strahlungsphysik (DIN 5031-1:1982).

- 20. ISO 9845-1:1992-10 Solar Energy; Reference Solar Spectral Irradiance at the Ground at Different Receiving Conditions; part 1: Direct Normal and Hemispherical Solar Irradiance for Air Mass 1.5 (ISO 9845-1:1992).

NOTES

*通讯作者。