Design

Vol.

06

No.

03

(

2021

), Article ID:

45067

,

6

pages

10.12677/Design.2021.63008

3D打印技术应用于家具五金之材料特性

谢淳钰,李芃萱

中原大学,室内设计学系,桃园 台湾

收稿日期:2021年8月2日;录用日期:2021年9月2日;发布日期:2021年9月8日

摘要

19世纪工业革命为求商品大量且快速的生产,生产过程开始推崇机械化、标准化及系统化,将手工艺术取而代之;现今组构家具造型之五金要件更是深受影响。家具造型之构成形式系藉由五金要件为媒介而产生链接,其关系密不可分。透过3D打印技术少量定制和多样化的制造优势(Bateman, R. J. & Cheng, K., 2006),其能够增加家具造型之多样化以成为当今发展之趋势,并足以解决现今对于造型多元之家具形式需求。本研究之目的系希望通过3D打印技术,解决硬件于大量生产中引起之单一化瓶颈,探讨其与木构造家具之发展可能性,并透过同一型态在不同3D打印材料下之接合形式差异。研究方法如下:1. 现阶段3D打印之家具五金要件盘点,针对其影响家具型态之限制做进一步测试并改善。2. 透过不同材料之3D打印实作,材料为ABS、PLA,打印之家具五金要件与木构型态之家具结合并比较其接合形式差异,探讨其发展造型之可能性。结论为发掘3D打印技术应用于家具五金要件产生之限制,改善连结家具之五金要件,再藉由相异之3D打印材料进行测试,将3D打印技术应用于木构造家具设计,建构与以往截然不同之五金制成新形式。

关键词

3D打印,3D打印材料,家具五金,型态

The Material Characteristics of 3D Printing Technology Applied to Furniture Hardware

Chun-Yu Hsieh, Peng-Hsuan Lee

Department of Interior Design, Chung Yuan Christian University, Taoyuan Taiwan

Received: Aug. 2nd, 2021; accepted: Sep. 2nd, 2021; published: Sep. 8th, 2021

ABSTRACT

In the 19th century, the industrial revolution sought to produce a large number of goods quickly. The production process began to advocate mechanization, standardization and systematization, replacing manual art; the hardware shapes of modern furniture modeling are deeply affected. The form of furniture modeling is connected by hardware components as the medium, and the relationship is inseparable. Through the small customization and diversified manufacturing advantages of 3D printing technology (Bateman, R.J. & Cheng, K., 2006). It can increase the diversification of furniture shapes to become the current development trend, and it is sufficient to solve the current diversified furniture forms demand. The purpose of this research is to use 3D printing technology to solve the simplification bottleneck caused by hardware in mass production, explore the possibility of its development with wooden furniture, and through the same type of bonding under different 3D printing materials difference. The research methods are as follows: 1. At the present stage, 3D printing furniture hardware components are counted, and further tests and improvements are made for the restrictions that affect the type of furniture. 2. Through the implementation of 3D printing of different materials, the materials are ABS, PLA, the hardware components of the printed furniture are combined with the furniture of the wooden structure, and the differences in the joint form are compared to explore the possibility of its development. The conclusion is to explore the limitations of the application of 3D printing technology to the production of furniture hardware components. Improve the hardware components of the furniture, and then use different 3D printing materials to test and apply 3D printing technology to wood constructing furniture design. Construct a new form of hardware making that is completely different from the past.

Keywords:3D Printer, 3D Printing Materials, Furniture Hardware, Form

Copyright © 2021 by author(s) and Hans Publishers Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY 4.0).

http://creativecommons.org/licenses/by/4.0/

1. 引言

3D打印的使用使客制化的创新变得轻易上手,工业模块化的高成本已不再是阻碍,在家具设计上也有机会开始探索、实验和原型开发。增材制造(AM)在设计行业的应用日益增加,虽然与部件之大量打印以及高强度材料的高生产成本相矛盾,但在制造物理原型降低设计开发过程中的成本变成了趋势。然而,其无法提供仅在使用实际和功能组件进行打印时获得的经验数据。故以市售木板板料易取得之尺寸作为选定的板材,经切割统一几何形状后,以3D打印组件创建家具型态。以下着重于打印过程之材料特性差异进行比较,使数据可以在不同打印方法下做出创意性的结合。本研究以FDM打印材料做比较,通过与相异材料进行连接以追求家具设计中五金材料打印之型态,创建出新型家具造型。研究步骤:确认板材尺寸及切割方式,3D打印材料选定及特性分析,五金要件设计及打印,组装流程,修正与结语。

2. 确认板材尺寸及切割方式

工业革命后,系统家具之系统化与规格化之特点符合了工业化大量生产的精神。系统家具多为板材以垂直水平方式组装成体,以柜体来说,其核心概念为侧板「32 mm系统」打出成排的洞,孔距为32 mm,用以定位结构、五金 [1] [2]。柜体结构依照板件之结合方式分为H结构、T结构、共享侧板、中立板结构及开放架结构(无背板)等,主要具有拆装方便、结构简洁、接合牢固、方便运输、包装及追加延伸,功能性强等特色。本研究之板材选用夹板,以奇数层薄木片交迭压制而成,各种厚度尺寸皆有,结构承重力甚至优于塑合板,在尺寸方面以市售较易取得之120 × 240公分尺寸之板材,以几何三角形分割,其三边长为30 cm、60 cm、67 cm,角度为30度、60度、90度,直至用尽板材,得数量为32片,无板材剩料。

3. 3D打印材料选定及特性分析

以热塑性材料而言,ABS及PLA为市占率较高之3D打印线材,且由于现今桌上型3D打印机的普及,在两者材料之使用上更易取得且好操作,故为本研究选择之材料。

3.1. ABS

ABS为丙烯腈丁二烯苯乙烯(Acrylonitrile Butadiene Styrene)材料,熔点(Melting Point)在210~240℃,打印温度在240~270℃,玻璃转化温度(Glass Transition Temperature)于105℃,其特色在于电镀性能与韧性佳,及此线材容易遇热成形,透过喷头挤压出线材,且需靠加热平台来稳定材料的黏着性,线材特性冷缩性高,若温度差距过大,会造成线材不易凝固,呈现液体状。因喷头属挤压式打印,线材会透过设定路径输出,在输出的过程中发现,以实际尺寸的五金要件会因部件之公差而造成组装上困难,考虑线材热缩性,需调整数字模型尺寸,将对象尺寸外推0.1 cm,后续才能顺利在实体进行组装 [3] [4] [5]。

3.2. PLA

PLA为聚乳酸(Polylactic Acid)材料,熔点(Melting Point)在160~190℃,打印温度在190~220℃,玻璃转化温度(Glass Transition Temperature)于65~70℃,PLA的熔体黏度与温度密切相关,由于材料来自玉米和甘蔗等农作物,可再生、可生物降解,在试用上,因其熔点较低,可使用较便宜的打印机,且收缩率较ABS低,对平台之加热依赖性也相对较低而较易上手,相较于其他热塑性塑料(如ABS)毒性小,使用上较安心 [3] [4] [5]。

4. 五金要件设计与打印

依照五金要件接合要点重新设计,以贴合板材同时具有轻巧性为设计出发,探讨不同于以往以五金造型定义家具型态,在设计之初先拟定设计目标与原则,供往后设计过程中进行调整与修正,并能在设计完成之后进行检核。本研究考虑以下几点元素,并整理如下表1,藉此设定本研究在家具五金要件之设计目标为造型、力学与节点出发 [6] [7] [8]。

Table 1. Design goals and principles

表1. 设计目标与原则

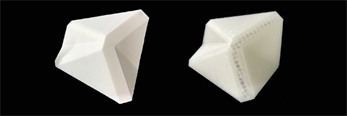

图1为本研究设计之打印五金要件,分别为组件A与组件B,设计发想以板材分割后之三边30度、60度、90度为一向,在组件A多考虑接触地面之稳定性而设计(图1 (左)),组件B将其镜射得出6角之组件(图1 (右))。

Figure 1. Component A (left) & Component B (right)

图1. 组件A (左)与组件B (右)

在数字生产过程前,数字模型在Rhino建构并汇出转存为Stl格式之档案,提供切片软件计算格式。输出步骤为:在网格公差输入0.01、勾选细分网格、贴图坐标不重迭、文件类型选则二进制,以确保在输出过程中与数字模型为一致性。使用ABS及PLA材质进行打印并于下表2列出其打印过程差异 [3] [4] [5]。

Table 2. 3D printing value table

表2. 3D打印数值表

4. 组装流程

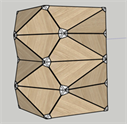

以总尺寸为120 × 240 cm进行分割 ,透过等分将板材均分为12等份,再以勾30 × 股60 cm所形成之三角形共32片。以两片三角形之股边对接,并透过弦边之镜射,再以每4片三角形为一单位,排列方式以60长边对接,67之长边镜射,其角度合分别为60度、120度、240度,在其20个节点处以3D打印组件方式固定,组件分为2个形态组件A及组件B,组件设计以拼接成之单元体形成环状方式头尾相接,一单元体为16个三角形组成,组件A连接顶部及端部,如下图2第一步骤,组件B于中段进行连接,如下图中第二步骤。

Figure 2. Assembly process

图2. 组装流程

5. 修正与结语

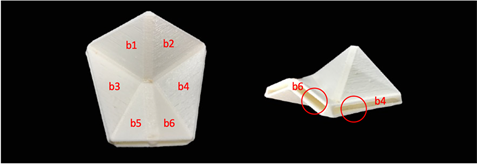

在打印过程中发现,以ABS材料打印之组件B与木板接点处厚度打印不佳,在各条件数值相同的情况下,组件B之面b5、b6为正常,分别于b1、b2、b3、b4出现异常状况,b4相较b6而言(如下图3),打印纹理明显参差、密合度差,因而尝试在切片时单独测试其数值变化是否影响组件之打印原因,最终发现在调整打印壁厚(Layer Thickness)由0.19调整至0.14后,问题改善,打印质量也较均匀。

Figure 3. Component B 3D printing quality

图3. 组件B打印质量

本实验成果,就硬度来说,PLA较ABS质地坚硬;就细致度来说,PLA打印纹理较明显且光滑;就可弯曲性来说,在弯曲时ABS较PLA易断裂;就韧性来说,PLA因材料特性较脆而较ABS韧性差,考虑各项材料特性后,硬度、韧性及弯曲度着重于家具中段节点之大角度支撑,将组件B以ABS打印,而PLA纹理面考虑上选择于端部与顶部打印五金要件,为组件A。

本篇结论着重于3D打印应用于创作上之木构造造型限制,其一是家具五金需乘载本身之重量,设计者在打印过程需对3D打印各向化学黏着特性有充分了解 [9],除了能提升对象打印成功率,也能利用打印原理增强其强度,并在与异材质接合时保有设计造型之美观;其二是在材料上的应用,比较ABS及PLA,此为市占率较高之3D打印材料,在应用上发现彼此皆具优劣势,在处理上需注意材料本身之特性因素,ABS对温度较敏感,打印之对象较细致且具一定程度之韧性;PLA则较脆,受到不均匀之外力影响时较易断裂,打印对象有较显著之棱角,在造型可增加其对象之利落感。而在与异材质接合上,ABS需考虑到对象之打印公差,预留接合时所需之间隙;PLA则需考虑到与异材质接合时之施力状况,避免对象受到瞬间之外力影响而造成断裂。

致谢

台湾中原大学CDRL研究室。

文章引用

谢淳钰,李芃萱. 3D打印技术应用于家具五金之材料特性

The Material Characteristics of 3D Printing Technology Applied to Furniture Hardware[J]. 设计, 2021, 06(03): 46-51. https://doi.org/10.12677/Design.2021.63008

参考文献

- 1. 王榆宣. 竹管结合木材之座椅结构[D]: [硕士学位论文]. 屏东: 台湾屏东科技大学, 2011.

- 2. 徐文彬. 室内系统家具多样化组合之研究[D]: [硕士学位论文]. 桃园: 台湾中原大学, 2017.

- 3. Wittbrodta, B. and Pearce, J.M. (2015) The Effects of PLA Color on Material Properties of 3-D Printed Components. Additive Manufacturing, 8, 110-116. https://doi.org/10.1016/j.addma.2015.09.006

- 4. Behzadnasab, M. and Yousefi. A.A. (2016) Nozzle Temperature Effect on 3D Printed Structure Properties. 12th International Seminar on Polymer Science and Technology.

- 5. Veselý, P. (2019) Nozzle Temperature Effect on 3D Printed Structure Properties. Elektrotechnológia 2019.

- 6. Raspall, F., Banon, C. and Tay, J.C. (2019) AirTable: Stainless Steel Printing for Functional Space Frames. Proceedings of the 24th CAADRIA Conference, Victoria University of Wellington, Wellington, New Zealand, 15-18 April 2019, 113-122.

- 7. Hsieh, C.C.Y. and Ku, S.W. (2019) The Research on the Characteristics of Furniture Hardware Design Through 3D Printing. In: Stephanidis, C., Ed., HCI International 2019-Posters, HCII 2019, Communications in Computer and Information Science, Vol. 1032. Springer, Cham, 339-347. https://doi.org/10.1007/978-3-030-23522-2_44

- 8. Raspall, F., Banon, C. and Toh, H.P. (2019) Into Lightness: Furniture as Proxies for Radical Experimental Structural Design Using Advanced Manufacturing. Proceedings of IASS Annual Symposia, IASS 2019 Barcelona Symposium: Advanced Manufacturing and Non-Conventional Materials, Barcelona, Spain, 7-10 October 2019, 1-8.

- 9. Zareiyan, B. and Khoshnevis, B. (2017) Interlayer Adhesion and Strength of Structures in Contour Crafting-Effects of Aggregate Size, Extrusion Rate, and Layer Thickness. Automation in Construction, 81, 112-121. https://doi.org/10.1016/j.autcon.2017.06.013