Material Sciences

Vol.07 No.06(2017), Article ID:21952,9

pages

10.12677/MS.2017.76075

Research Progress on Photodarkening of Yb-Doped Fiber

—Sol-Gel Method to Suppress Photodarkening

Fenghou Xie1,2, Chunlei Yu1, Suya Feng1, Lili Hu1

1Shanghai Institute of Optics and Fine Mechanics, the Chinese Academy of Sciences, Shanghai

2University of Chinese Academy of Sciences, Beijing

Received: Aug. 5th, 2017; accepted: Aug. 31st, 2017; published: Sep. 6th, 2017

ABSTRACT

Photodarkening of high power Yb-doped fiber lasers leads to the decrease of laser power, which limits the further development of high power laser. Therefore, it is significantly important to study the photodarkening behavior of Yb-doped fiber lasers. Firstly, the research progress of photodarkening in Yb-doped fiber is reviewed in this paper, including characterization, impact factors, mechanism, and suppression. Then based on the research progress of Sol-Gel method, it is proposed that the Yb-doped fiber prepared by Sol-Gel method may inhibit photodarkening.

Keywords:Yb-Doped Fiber, Photodarkening, Bleach, Sol-Gel Method

掺镱光纤光暗化研究进展

——溶胶凝胶法抑制光暗化

谢封侯1,2,于春雷1,冯素雅1,胡丽丽1

1上海光学精密机械研究所,上海

2中国科学院大学,北京

收稿日期:2017年8月5日;录用日期:2017年8月31日;发布日期:2017年9月6日

摘 要

高功率掺镱光纤激光器的光暗化现象导致激光器功率降低,阻碍了激光器功率的进一步提升,因此研究掺镱光纤光暗化现象对促进掺镱光纤激光器的发展具有重要意义。本文首先从光暗化的表征、光暗化对激光器的影响及其机理,光暗化的影响因素及抑制手段方面对光暗化进行了综述,阐述了光暗化的研究进展;然后简单介绍了采用溶胶凝胶法工艺制备掺镱光纤的研究进展,并提出了采用溶胶凝胶法制备的掺镱光纤可能具有抑制光暗化效果的猜想。

关键词 :掺镱光纤,光暗化,漂白,溶胶凝胶法

Copyright © 2017 by authors and Hans Publishers Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

1. 引言

近年来,基于惯性约束核聚变 [1] 、激光加工 [2] 以及军事领域发展的需求,高功率掺镱石英光纤受到国内外研究团队的广泛关注。目前,国外已经实现光纤万瓦级单模激光的输出 [3] ,并已经有成熟的激光产品。而国内虽然也成功研发出2万瓦多模光纤激光器 [4] ,但并没有万瓦级单模激光器,与国外相比仍有较大差距。同时,随着高功率激光器运行时间的增加,掺镱光纤激光器由于光暗化导致激光阈值功率上升和激光输出功率降低的现象 [5] ,严重影响了激光器的可靠性和稳定性,并限制了掺镱光纤激光器功率的进一步提高。

掺镱光纤激光器面临的光暗化问题,主要是在近红外光子泵浦下,光纤中产生色心,在紫外–可见甚至到近红外光波长范围的吸收随工作时间的增加而增加,增大了光纤对泵浦光和激光的损耗,降低激光器的效率和稳定性。为解决光暗化带来的不利影响,国外研究人员对此展开了深入的研究,并做了大量的报道,但光暗化的机理研究仍存在争议。而国内对其研究和报道却较少,基于此,本文首先从光暗化的表征、光暗化对激光器的影响及其机理,光暗化的影响因素及抑制手段方面对光暗化进行了综述,阐述了光暗化的研究进展,简单介绍了采用溶胶凝胶法工艺制备掺镱光纤的研究进展,并提出了采用溶胶凝胶法制备的掺镱光纤可能具有抑制光暗化效果的猜想。

2. 光暗化表征

1997年,Paschotta等 [6] 首次在掺镱石英光纤中发现了光暗化现象。他们在采用976 nm作为泵浦光泵浦掺镱光纤时,观测到光纤荧光输出和光纤中的剩余泵浦光急剧下降,由此认为光纤中可能存在某些杂质或缺陷的形成,导致了对泵浦光的不饱和吸收,从而影响了激光器的性能。但是当时并未对此展开深入研究,也没有提出适当的方法来表征不饱和吸收程度的大小。

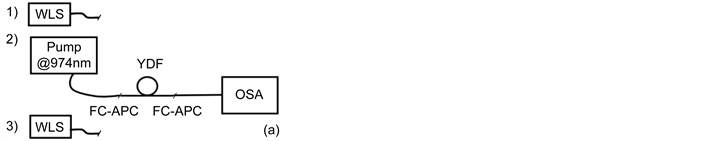

2005年,Koponen等 [7] 首次详细的提出了光暗化的表征方法,文中提到的光暗化测试原理如图1 [7] 所示,图2 [7] 是测试所得的诱导损耗谱。图1(a)是光纤暗化前后的光谱测试装置,图1(b)是光暗化测试原理图。首先,将白光耦合进光纤测得光纤透过谱,随后采用974 nm泵浦光纤30分钟后再次测得光纤透过谱,通过对比光纤光暗化前后透过谱,计算出光暗化引起的诱导损耗谱,如图2(a)所示。从图2(b)可以看出,在1040~1070 nm处的诱导损耗是633 nm处的诱导损耗的71倍。由于光暗化在633 nm处的诱导损耗变化比激光波长处的诱导损耗变化明显,采用633 nm作为探针光具有更高的信噪比,因此在光暗化测试过程中,通常采用633 nm探针光透过率变化来表征光暗化程度。

Figure 1. Schematic configuration of (a) spectrum; (b) photodarkening measurement [7]

图1. 测试装置:(a) 光谱;(b) 光暗化 [7]

Figure 2. (a) Induced loss spectrum; (b) Relationship between the induced loss at 633 nm and 1040 - 1070 nm [7]

图2. (a) 光暗化诱导损耗谱;(b) 633 nm与1040~1070 nm处诱导损耗关系图 [7]

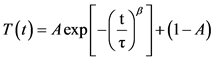

(1)

(1)

采用633 nm激光作为探针光的光暗化测试光路如图1(b)所示,以974 nm半导体激光作为泵浦光,通过波分复用器(WDM)将两束光耦合进掺镱光纤纤芯中,功率计实时记录633 nm功率变化,并采用拉伸指数(l)对633 nm探针光归一化透过率拟合,可得到表征光暗化程度的3个参量,1 − A是短期稳态透过率, 是时间常量,

是时间常量, 是拉伸因子。

是拉伸因子。

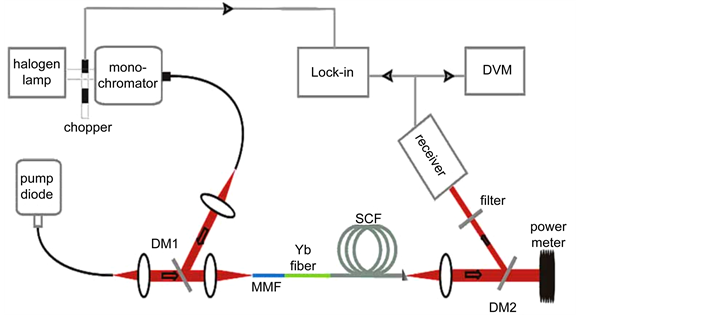

2007年,Jestchke等 [8] 采用915 nm包层泵浦方式诱导光纤暗化,文中采用图3 [8] 作为测试装置原理图。光路采用空间耦合方式,通过氙灯分出633 nm光作为探针光,由于分光后633 nm光功率极低,实验中采用锁模放大器装置来提高信噪比。

2011年,Olivero等 [9] 指出,光暗化测试如果采用包层泵浦方式,需要较高的泵浦功率才能达到较高的粒子数反转度,而且包层吸收较小,需要较长光纤测试,测试光纤利用率低。而采用芯泵的方式不仅可以用很小的泵浦功率,很短的光纤就能使光纤快速暗化,而且光路中各部分可以熔接在一起,光路简单,缩短了测试时间并降低了测试成本,为企业和科研单位提供了一个快速表征光纤光暗化性能的方法,其测试光路图如图4 [9] 所示。

3. 光暗化对激光器的影响

掺镱光纤面临的光暗化问题,主要是因为Yb3+吸收的泵浦光能量传递给光纤基质,在光纤中形成了色心,其对激光器最主要的影响包括以下三个方面。

1) 增加背景损耗,降低激光输出功率

Figure 3. Schematic configuration of photodarkening measurement by cladding pump [8]

图3. 包层泵浦方式光暗化测试装置

Figure 4. Schematic configuration of photodarkening measurement [9]

图4. 全光纤光路光暗化测试装置图 [9]

光暗化对掺镱激光器最明显的影响就是增加背景损耗,降低激光器的激光输出功率,严重时甚至不出激光。2007年,Manek-Hönninger等 [10] 发现随着暗化时间越长,紫外–近红外的吸收逐渐增加,其激光输出功率下降也越明显。

2) 降低Yb3+荧光寿命

2014年,Piccoli等 [11] 研究光暗化对Yb3+荧光寿命的影响时发现,光暗化会降低Yb3+荧光寿命,并且Yb3+荧光寿命的减小量与光暗化产生的诱导损耗呈线性关系。同年,Li等 [12] 也观测到暗化后的光纤荧光寿命降低12%的现象。

3) 光暗化导致温升,降低模式不稳定阈值

2010年,Ponasoda等发现光暗化会诱导光纤温度上升,并且光纤温度变化与光暗化存在线性关系。2015年,Otto等 [13] 对比实验结果和模拟结果发现,光暗化是光纤中的第二个热源,光暗化可明显的增加光纤的热负载,降低高阶模式不稳定阈值。

4. 光暗化机理

十余年来,随着光暗化表征手段的确立,人们对光暗化开展了大量的研究。虽然研究人员普遍认为色心的形成与处于激发态的Yb3+离子向掺镱石英光纤的紫外吸收带发生能量转移有关,但是对于紫外吸收带的起源存在争议,目前主要有两种观点:氧缺陷中心(ODC)和电荷转移吸收带(CT)。

2007年,Yoo等 [14] 发现掺镱光纤在220 nm附近存在紫外吸收峰,并认为该吸收带是由Yb3+相关的氧空位缺陷(ODC)引起的,该ODC是光暗化色心前驱体,通过吸收能量后释放出的电子被Yb3+、Al3+捕获,形成色心。

同年,瑞典中部大学的Engholm等 [15] 认为240 nm吸收带是由于Yb3+与最近邻的O2−之间存在着电子跃迁吸收引起的,该吸收带是光暗化过程中能量转移中间态,并不会直接导致光暗化现象。

由于紫外吸收带的起源存在争议,导致低能量的近红外泵浦或发射光子向高能量的紫外吸收带发生能量转移的路径也存在争论,但是不可否认的是,研究者们普遍认为光暗化效应与Yb3+团簇有密切联系,并且认为形成一个导致光暗化的色心的能量需要n个(2~7个 [8] [16] [17] [18] )Yb3+离子共同提供,由于测试条件不同 [17] ,n的具体数值存在较大差异。

5. 光暗化的影响因素及抑制方法

虽然人们对光暗化色心的产生机理仍没有一致的看法,但是对于光暗化具体影响因素的研究工作却有很多,并根据这些影响因素提出了一些有效的抑制光暗化方法。

1) 光纤制备气氛环境对光暗化的影响

2005年,Jasapara等 [19] 采用H2处理掺镱光纤14小时,再用976 nm激光泵浦20分钟,发现其吸收光谱并未改变,光纤并未出现暗化现象,而未经处理的光纤损耗增加,暗化现象明显。2008年,Engholm等 [20] 和Jetschke等 [21] 也发现在还原环境或者氢气环境下能有效抑制光纤光暗化,这主要是因为H2在光暗化过程中扮演空穴捕获中心的角色,消除了色心。

2007年,Yoo等 [14] 用488 nm泵浦加载氧气后和未载氧的掺镱光纤,发现载氧后的光纤在633 nm处的诱导损耗较未载氧的低,因而认为氧气处理可以消除光暗化色心前驱体——Yb3+相关的氧空位(ODC),通过载氧有利于抑制光暗化。因此采用氢气还原或者载氧均能作为抑制光暗化的有效手段。

2) 光纤材料对光暗化的影响

作为光暗化的载体,光纤材料本身对光暗化起着决定性的作用,通过优化光纤的材料,可以达到降低甚至抑制光暗化的目的。光纤材料对光暗化的影响,主要包括Yb3+浓度、共掺离子这两个方面的影响。

2011年,Gebavi等 [22] 观测到掺镱光纤在513 nm和633 nm处的光暗化诱导损耗与Yb3+浓度成二次方关系,认为Yb3+浓度越高,Yb3+团簇的可能性越大,离子间能量的传递效率越高,更易产生光暗化。同年,Taccheo等也证实了光暗化诱导损耗与Yb3+浓度成二次方关系。

除了Yb3+浓度对光暗化的影响,共掺离子对光暗化的影响也很大。在掺Yb3+光纤中也可通过共掺Al、P、Ce、Er、F [23] 、碱土元素等离子达到抑制光暗化的作用,其抑制原理也各不相同。共掺Al、P抑制光暗化,主要是因为提高了Yb3+的分散性,减少了团簇,抑制了激发态Yb3+间能量的传递 [16] [24] - [33] 。共掺Ce离子降低光暗化 [34] [35] [36] [37] [38] 是因为要减少了引起光暗化的缺陷。光纤中Ce3+和Ce4+共存,Ce离子既能消除空穴,又能消除电子,减少了形成色心的空穴和电子,降低了缺陷形成的可能性。共掺Er离子抑制光暗化 [39] [40] 主要是因为增加去激发通道来避免达到高能级状态,削弱了Yb3+间能量传递。碱土金属(Mg2+, Ca2+, Sr2+, Ba2+) [41] [42] 的掺入主要是充当Yb3+的稳定剂,形成Mg2+-Yb3+-Yb3+, Al3+-Yb3+-Ca2+, Sr2+-Yb3+-Yb3+, Al3+-Yb3+-Ba2+等稳定的8电子结构,从而降低Yb3+-Yb2+-Yb3+, Al3+-Yb2+-Yb3+结构的形成几率,抑制电荷转移的发生,减少Yb2+的产生。

以上可以看出,通过优化材料组分能够明显的抑制光暗化。虽然共掺某些离子能够抑制光暗化,但对光纤的应用并不见得十分有利,比如共掺P会降低Yb3+的吸收和发射截面 [43] ,不利于发光;共掺Er会降低斜率效率 [39] 等,因此优化材料组分需要综合考虑以达到结果最优。

3) 温度对光暗化的影响

2009年,Leich等 [44] [45] 发现在一定温度范围内,通过加热光纤可加速光暗化,并且也可以使已暗化的光纤暗化程度下降。同年,Söderlund等 [46] [47] 采用加热的方式将暗化光纤恢复到暗化前的状态,并计算出漂白色心的热激活能远小于光暗化所需的激活能。

4) 紫外、可见光对光暗化的影响

2007年,Manek-Hönninger等 [10] 采用355 nm激光可快速且彻底地漂白已暗化的掺镱光纤。2013年,Gebavi等 [48] 采用976 nm和633 nm光泵浦掺镱光纤,发现激光功率下降程度比单独采用976 nm泵浦掺镱光纤时激光功率下降程度少,由此认为633 nm光具有漂白暗化光纤的作用。对于其他波长(405 nm [49] ,543 nm [50] , 793 nm [51] )光漂白的现象,也有文章报道,因此,采用紫外可见光注入能够实现缓解光暗化的效果。

6. 溶胶凝胶法制备掺镱光纤

2007年,Romano等 [52] 报道了溶胶凝胶法制备Yb3+/Al3+掺杂石英光纤工艺。制备的光纤在1100 nm的损耗为0.031 dB/m,斜率效率73%,激光输出功率34.2 mW。2008年,李毅刚等 [53] 也报道过采用溶胶–凝胶法制备的Yb3+掺杂石英光纤在1053 nm获得了106 mW的激光输出,斜率效率高达88.4%。

溶胶凝胶法是指将金属有机化合物或无机化合物经过水解缩聚过程逐渐凝胶化以及经过必要的热处理,最终得到氧化物或其他固体化合物的工艺方法。该方法的优点是可以进行多组分掺杂、掺杂浓度精确可控、分子级液态掺杂以及保证掺杂均匀性,采用该方法能够制得大尺寸、低损耗、高均匀度、分散性极高的Yb3+掺杂的石英粉体。

考虑到光暗化程度是由Yb3+团簇程度决定的,而溶胶凝胶法能更好地分散Yb3+,降低团簇,并且采用此法能够做大光纤芯径,有利于大模场光纤的制备,从而降低端面功率密度,抑制光暗化。因此,猜想在相同浓度下,采用溶胶凝胶法制备的掺镱光纤抗光暗化性能更强。

图5是本课题组分别采用改进的化学气相沉积法(MCVD法)和溶胶凝胶法(Sol-Gel法)制备的相同组分光纤的光暗化诱导损耗对比,可以看出采用溶胶凝胶法制备的掺镱光纤对光暗化具有一定的抑制作用,为抗光暗化掺镱光纤的制备提供了新途径,其具体的抑制机理将会通过后续实验进一步研究。

Figure 5. Induced losses of fiber prepared by MCVD and Sol-Gel method

图5. 采用MCVD法和Sol-Gel法制备的光纤诱导损耗对比

7. 总结及展望

掺镱光纤是掺镱光纤激光器的核心部件,解决光纤的光暗化问题对提升掺镱光纤激光器的功率具有重要的意义。虽然近年来抑制光暗化的手段层出不穷,但是要达到既抑制光纤光暗化,又不影响光纤激光性能的效果却很难。光暗化问题本质上与光纤材料相关,因此要彻底抑制光暗化还应从材料的制备工艺、组分改善等方面展开研究。本文初步得到了采用Sol-Gel法制备的光纤相较于MCVD法制备的光纤具有更强的抗光暗化性能的结果,这为制备抗光暗化掺镱光纤提供了新途径,但是其抑制机理还需要进行更深入的研究,从而进一步揭示光暗化的内在机理。

文章引用

谢封侯,于春雷,冯素雅,胡丽丽. 掺镱光纤光暗化研究进展——溶胶凝胶法抑制光暗化

Research Progress on Photodarkening of Yb-Doped Fiber—Sol-Gel Method to Suppress Photodarkening[J]. 材料科学, 2017, 07(06): 567-575. http://dx.doi.org/10.12677/MS.2017.76075

参考文献 (References)

- 1. Kilkenny, J.D., Alexander, N.B., Nikroo, A., Steinman, D.A. and Nobile, A. (2005) Laser Targets Compensate for Limitations in Inertial Confinement Fusion Drivers. Laser & Particle Beams, 23, 475-482. https://doi.org/10.1017/S0263034605050664

- 2. Hoult, T. 准连续激光器在焊接应用中的突破[J]. 金属加工: 热加工, 2016(4): 31-33.

- 3. Gapontsev, V., Fomin, V., Ferin, A. and Abramov, M. (2010) Diffraction Limited Ul-tra-High-Power Fiber Lasers.

- 4. 中国光电网. 我国首台2万瓦光纤激光器正式装机打破国外技术垄断[EB/OL]. http://www.optochina.net/html/zx/xw/48008.html, 2016.

- 5. 朱宗玖, 许立新, 毛庆和, 刘文清. 高掺杂浓度掺镱光纤的光子暗化效应[J]. 光子学报, 2007(36): 26-29.

- 6. Paschotta, R., Nilsson, J., Barber, P.R., Caplen, J.E., Tropper, A.C. and Hanna, D.C. (1997) Lifetime Quenching in Yb-Doped Fibres. Optics Communications, 136, 375-378. https://doi.org/10.1016/S0030-4018(96)00720-1

- 7. Koponen, J.J., Söderlund, M.J. and Tammela, S.K.T. (2005) Photodarkening in Ytterbium-Doped Silica Fibers. Proceedings of SPIE, 5990, 72-81. https://doi.org/10.1117/12.630499

- 8. Jetschke, S., Unger, S., Röpke, U. and Kirchhof, J. (2007) Photodarkening in Yb-doped Fibers: Experimental Evidence of Equilibrium States Depending on the Pump Power. Optics Express, 15, 14838-14843. https://doi.org/10.1364/OE.15.014838

- 9. Olivero, M., Boetti, N., Milanese, D. and Perrone, G. (2011) Meas-urement Techniques for the Evaluation of Photodarkening in Fibers for High-Power Lasers. Proceedings of SPIE, 7914, 79142U-79142U-6. https://doi.org/10.1117/12.876276

- 10. Manek-Hönninger, I., Boullet, J., Cardinal, T., Guillen, F., Ermeneux, S., Podgorski, M., Bello, D.R. and Salin, F. (2007) Photodarkening and Photobleaching of an Ytterbium-Doped Silica Double-Clad LMA Fiber. Optics Express, 15, 1606-1611. https://doi.org/10.1364/OE.15.001606

- 11. Piccoli, R., Robin, T., Méchin, D. and Taccheo, S. (2014) Impact of Photodarkening on Yb Lifetime in Al-Silicate Fibres and on the Rate-Equation System. SPIE OPTO.

- 12. Nanxi, L., Seongwoo, Y., Xia, Y., Jain, D. and Sahu, J.K. (2014) Pump Power Depreciation by Photodarkening in Ytterbium-Doped Fibers and Amplifiers. IEEE Photonics Technology Letters, 26, 115-118. https://doi.org/10.1109/LPT.2013.2289965

- 13. Otto, H., Modsching, N., Jauregui, C., Limpert, J. and Tünner-mann, A. (2015) Impact of Photodarkening on the Mode Instability Threshold. Optics Express, 23, 15265-15277. https://doi.org/10.1364/OE.23.015265

- 14. Yoo, S., Basu, C., Boyland, A.J., Sones, C., Nilsson, J., Sahu, J.K. and Payne, D. (2007) Photodarkening in Yb-Doped Aluminosilicate Fibers Induced by 488 nm Irradiation. Optics Letters, 32, 1626-1628. https://doi.org/10.1364/OL.32.001626

- 15. Engholm, M., Norin, L. and Aberg, D. (2007) Strong UV Absorption and Visible Luminescence in Ytterbium-Doped Aluminosilicate Glass under UV Excitation. Optics Letters, 32, 3352-3354. https://doi.org/10.1364/OL.32.003352

- 16. Kilabayashi, T., Ikeda, M., Nakai, M., Sakai, T., Himeno, K. and Ohashi, K. (2006) Population Inversion Factor Dependence of Photodarkening of Yb-Doped Fibers and Its Suppression by Highly Aluminum Doping. Optical Fiber Communication Conference, 2006 and the 2006 National Fiber Optic Engineers Conference.

- 17. Jetschke, S. and Röpke, U. (2009) Power-Law Dependence of the Photo-darkening Rate Constant on the Inversion in Yb Doped Fibers. Optics Letters, 34, 109-111. https://doi.org/10.1364/OL.34.000109

- 18. Koponen, J., Laurila, M. and Hotoleanu, M. (2008) Inversion Behavior in Core- and Cladding-Pumped Yb-Doped Fiber Photodarkening Measurements. Applied Optics, 47, 4522-4528. https://doi.org/10.1364/AO.47.004522

- 19. Jasapara, J., Andrejco, M., Digiovanni, D. and Windeler, R. (2006) Effect of Heat and H2 Gas on the Photo-Darkening of Yb+3 Fibers. Quantum Electronics and Laser Science Conference Lasers and Electro-Optics, CLEO/QELS 2006.

- 20. Engholm, M. and Norin, L. (2008) Reduction of Photodarkening in Yb/Al-Doped Fiber Lasers. Proceedings of SPIE the International Society for Optical Engineering, 6873. https://doi.org/10.1117/12.763218

- 21. Jetschke, S., Unger, S., Leich, M., Reichel, V. and Kirchhof, J. (2008) Photodarkening in Yb-Doped Silica Fibers: Influence of the Atmosphere during Preform Collapsing. Proceedings of SPIE—The International Society for Optical Engineering, 68731G. https://doi.org/10.1117/12.776638

- 22. Gebavi, H., Taccheo, S., Milanese, D., Monteville, A., Le, G.O., Landais, D., Mechin, D., Tregoat, D., Cadier, B. and Robin, T. (2011) Temporal Evolution and Correlation between Cooperative Luminescence and Photodarkening in Ytterbium Doped Silica Fibers. Optics Express, 19, 25077-25083. https://doi.org/10.1364/OE.19.025077

- 23. Schuster, K., Grimm, S., Kalide, A., Dellith, J., Leich, M., Schwuchow, A., Langner, A., Schötz, G. and Bartelt, H. (2015) Evolution of Fluorine Doping Following the REPUSIL Process for the Adjustment of Optical Properties of Silica Materials. Optical Materials Express, 5, 887-897. https://doi.org/10.1364/OME.5.000887

- 24. Shubin, A.V., Yashkov, M.V., Melkumov, M.A. and Smirnov, S.A. (2007) Photodarkening of Alumosilicate and Phosphosilicate Yb-Doped Fibers. European Conference on Lasers and Electro-Optics, 2007 and the International Quantum Electronics Conference.

- 25. Jetschke, S., Unger, S., Schwuchow, A., Leich, M. and Kirchhof, J. (2008) Efficient Yb Laser Fibers with Low Photodarkening by Optimization of the Core Composition. Optics Express, 16, 15540-15545. https://doi.org/10.1364/OE.16.015540

- 26. Mattsson, K.E., Knudsen, S.N., Cadier, B. and Robin, T. (2008) Photo Darkening in Ytterbium Co-Doped Silica Material. Lasers and Applications in Science and Engineering, San Jose, 25 February 2008, 68731C.

- 27. Kirchhof, J., Unger, S., Jetschke, S., Leich, M. and Reichel, V. (2009) Yb-Doped Silica-Based Laser Fibers: Correlation of Photodarkening Kinetics and Related Optical Properties with the Glass Composition. Proceedings of SPIE—The International Society for Optical Engineering, 7195, 71950S. https://doi.org/10.1117/12.808918

- 28. Suzuki, S., Mckay, H.A., Peng, X., Fu, L. and Dong, L. (2009) Highly Ytterbium-Doped Silica Fibers with Low Photo-Darkening. Optics Express, 17, 9924-9932. https://doi.org/10.1364/OE.17.009924

- 29. Laperle, P., Desbiens, L. and Proulx, A. (2010) Relations between Phosphorus/Aluminum Concentration Ratio and Photodarkening Rate and Loss in Yb-Doped Silica Fibers. Proceedings of SPIE—The International Society for Optical Engineering, 7580, 75801Y.

- 30. Deschamps, T., Ollier, N., Vezin, H. and Gonnet, C. (2012) Clusters Dissolution of Yb3+ in Codoped SiO2-Al2O3-P2O5 Glass Fiber and Its Relevance to Photodarkening. Journal of Chemical Physics, 136, Article ID: 014503. https://doi.org/10.1063/1.3673792

- 31. Jetschke, S., Unger, S., Leich, M. and Kirchhof, J. (2012) Photodarkening Kinetics as a Function of Yb Concentration and the Role of Al Codoping. Applied Optics, 51, 7758-7764. https://doi.org/10.1364/AO.51.007758

- 32. Kim, S.J., Hujimaki, Y., Taniguchi, H., Kinoshita, H. and Sato, K. (2014) Fabrication and Characterization of a Phosphosilicate YDF with High Yb Absorbance and Low Background Loss. Proceedings of SPIE—The International Society for Optical Engineering, Vol. 8961, 18-20.

- 33. Rybaltovsky, A.A., Bobkov, K.K., Umnikov, A.A. and Dianov, E.M. (2014) The Yb-Doped Aluminosilicate Fibers Photodarkening Mechanism Based on the Charge-Transfer State Excitation. Proceedings of SPIE—The International Society for Optical Engineering, Vol. 8961, 18-20.

- 34. Engholm, M., Jelger, P., Laurell, F. and Norin, L. (2009) Improved Photo-darkening Resistivity in Ytterbium-Doped Fiber Lasers by Cerium Codoping. Optics Letters, 34, 1285-1287. https://doi.org/10.1364/OL.34.001285

- 35. Jelger, P., Engholm, M., Norin, L. and Laurell, F. (2010) Degrada-tion-Resistant Lasing at 980 nm in a Yb/Ce/Al-Doped Silica Fiber. Journal of the Optical Society of America B, 27, 338-342. https://doi.org/10.1364/JOSAB.27.000338

- 36. Sheng, Y., Yang, L., Luan, H., Liu, Z., Yu, Y., Li, J. and Dai, N. (2012) Improvement of Radiation Resistance by Introducing CeO2 in Yb-Doped Silicate Glasses. Journal of Nuclear Materials, 427, 58-61.

- 37. Chen, G., Wang, Y.B., Xie, L. and Xing, Y.B. (2013) Self-Bleaching Phenomenon Ob-served in the Ce/Yb Co-Doped Silica Fiber. CLEO: Science and Innovations, San Jose, 9-14 June 2013.

- 38. Unger, S., Jetschke, S. and Kirchhof, J. (2013) Optical Properties of Cerium-Codoped High Power Laser Fibers. Proceedings SPIE, 86, 5997-6001. https://doi.org/10.1117/12.2002399

- 39. Jetschke, S., Leich, M., Unger, S., Schwuchow, A. and Kirchhof, J. (2011) Influence of Tm- or Er-Codoping on the Photodarkening Kinetics in Yb Fibers. Optics Express, 19, 14473-14478. https://doi.org/10.1364/OE.19.014473

- 40. Morasse, B., Chatigny, S., Gagnon, É., Hovington, C., Martin, J. and Sandro, J.D. (2007) Low Photodarkening Single Cladding Ytterbium Fibre Amplifier.

- 41. Fujimoto, Y., Sugiyama, S., Murakami, M., Nakano, H., Sato, T. and Shiraga, H. (2013) Suppression Mechanism by Ca Additive of Photo-Darkening Effect in Yb-Doped Silica Glass Fiber. Lasers and Electro-Optics, San Jose, 9-14 June 2013, 1-2.

- 42. Sakaguchi, Y., Fujimoto, Y., Masuda, M., Miyanaga, N. and Nakano, H. (2016) Suppression of Pho-to-Darkening Effect in Yb-Doped Silica Glass Fiber by Co-Doping of Group 2 Element. Journal of Non-Crystalline Solids, 440, 85-89.

- 43. Reichel, V. (2009) Influence of Aluminum-Phosphorus Codoping on Optical Properties of Ytterbium-Doped Laser Fibers. Proceedings of SPIE—The International Society for Optical Engineering, 7212, 72121B.

- 44. Leich, M., Jetschke, S., Unger, S. and Reichel, V. (2009) Acceleration of Photodarkening Measurements in Yb-Doped Fibers by Enhanced Temperatures. European Conference on Lasers and Electro-Optics 2009 and the European Quantum Electronics Conference.

- 45. Leich, M., Röpke, U., Jetschke, S., Unger, S., Reichel, V. and Kirchhof, J. (2009) Non-Isothermal Bleaching of Photodarkened Yb-Doped Fibers. Optics Express, 17, 12588-12593. https://doi.org/10.1364/OE.17.012588

- 46. Söderlund, M.J., Jj, M.I.P., Koplow, J.P. and Honkanen, S. (2009) Thermal Bleaching of Photodarkening-Induced Loss in Ytterbium-Doped Fibers. Optics Letters, 34, 2637-2639. https://doi.org/10.1364/OL.34.002637

- 47. Söderlund, M.J. and Ponsoda, J.M.I. (2009) Heat-Induced Darkening and Spectral Broadening in Photodarkened Ytterbium-Doped Fiber under Thermal Cycling. Optics Express, 17, 9940-9946. https://doi.org/10.1364/OE.17.009940

- 48. Gebavi, H., Taccheo, S., Lablonde, L., Cadier, B., Robin, T., Méchin, D. and Tregoat, D. (2013) Mitigation of Photodarkening Phenomenon in Fiber Lasers by 633 nm Light Exposure. Optics Letters, 38, 196-198. https://doi.org/10.1364/OL.38.000196

- 49. Riccoli, R., Gebavi, H., Lablonde, L. and Cadier, B. (2013) Evidence of Photodarkening Mitigation in Yb-Doped Fiber Lasers by Low Power 405 nm Radiation. IEEE Photonics Technology Letters, 26, 50-53.

- 50. Chávez, A.D.G., Kir’Yanov, A.V., Barmenkov, Y.O. and Il’Ichev, N.N. (2007) Reversible Photo-Darkening and Resonant Photo-Bleaching of Ytterbium-Doped Silica Fiber at In-Core 977-nm and 543-nm Irradiation. Laser Physics Letters, 4, 734-739. https://doi.org/10.1002/lapl.200710053

- 51. Zhao, N., Xing, Y.B., Li, J.M., Liao, L., Wang, Y.B., Peng, J.G., Yang, L.Y., Dai, N.L., Li, H.Q. and Li, J.Y. (2015) 793 nm Pump Induced Photo-Bleaching of Photo-Darkened Yb3+-Doped Fibers. Optics Express, 23, 25272-25278. https://doi.org/10.1364/OE.23.025272

- 52. Pedrazza, U., Romano, V. and Lüthy, W. (2007) Yb: Al: Sol-Gel Silica Glass Fiber Laser. Optical Materials, 29, 905-907.

- 53. Chen, G., Li, H., Huang, J., Xu, L., Liu, L., Gu, S., He, Y., Li, Y. and Li, Y. (2009) Optical Properties and Laser Output of Heavily Yb-Doped Fiber Prepared by Sol-Gel Method and DC-RTA Technique. Journal of Lightwave Technology, 26, 3256-3260.