Hans Journal of Civil Engineering

Vol.

12

No.

07

(

2023

), Article ID:

68586

,

8

pages

10.12677/HJCE.2023.127107

水泥基材料超疏水改性方式以及改性材料

姚铃

重庆交通大学土木工程学院,重庆

收稿日期:2023年6月10日;录用日期:2023年7月1日;发布日期:2023年7月12日

摘要

水进入水泥基材料内部会引发冻胀开裂、化学侵蚀、碳化等问题,导致结构严重破坏,造成巨大的安全隐患和经济财产损失。对水泥基材料进行超疏水改性使得改性后的新型建筑材料具备更加优异的性能。本文综述了水泥基材料的两种超疏水改性方式(表面超疏水改性和整体超疏水改性);常用超疏水改性材料及其作用机理。最后,对水泥基材料超疏水改性的研究进行了归纳总结并对未来研究工作进行了展望。

关键词

超疏水性水泥基材料,表面超疏水改性,整体超疏水改性

Superhydrophobic Modification of Cement-Based Materials and Modified Materials

Ling Yao

School of Civil Engineering, Chongqing Jiaotong University, Chongqing

Received: Jun. 10th, 2023; accepted: Jul. 1st, 2023; published: Jul. 12th, 2023

ABSTRACT

The infiltration of water into cement-based materials can cause a range of problems including frost heave cracking, chemical erosion, carbonization, and other structural damage that may lead to significant safety risks and economic losses. To address this issue, superhydrophobic modification can be used to improve the impermeability, frost and ice resistance, and UV resistance of cement-based materials. This paper reviews two methods of superhydrophobic modification, surface superhydrophobic modification and global superhydrophobic modification, that have been used to modify cement-based materials. The paper also examines commonly used superhydrophobic modified materials and their mechanisms of action, the effects of superhydrophobic modification on the mechanical energy of cement-based materials for these materials. Finally, the research on superhydrophobic modification of cement-based materials is summarized, and future research prospects are discussed.

Keywords:Superhydrophobic Cement-Based Materials, Surface Superhydrophobic Modification, Overall Superhydrophobic Modification

Copyright © 2023 by author(s) and Hans Publishers Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY 4.0).

http://creativecommons.org/licenses/by/4.0/

1. 引言

水泥基材料由于其优异的力学性能和耐久性能成为世界上使用最广泛的建筑材料 [1] ,但由于其亲水性,环境中的水很容易携带腐蚀性物质通过混凝土孔隙进入混凝土内部,导致钢筋腐蚀或其他耐久性问题 [2] [3] [4] ,因此,有效防止水渗透对提高混凝土耐久性、延长建筑使用寿命至关重要。

过去几十年,降低水胶比和增加胶凝材料是两种常见的增强水泥基材料耐久性的方法 [5] ,但是这两种方法存在明显缺陷:降低了水泥基材料流动性、增加了水泥基材料硬化后的开裂风险。因此,基于“荷叶效应” [6] [7] ,研究人员提出了有效增强水泥基材料耐久性的方法——水泥基材料超疏水改性。

本文从超疏水改性方式、超疏水改性材料两个方面综述国内外超疏水水泥基材料的研究进展,以期为超疏水水泥基材料的科学研究和工程实际运用提供借鉴和参考。

2. 超疏水改性方式

根据润湿性理论模型,研究人员通过构造粗糙结构和降低表面能对水泥基材料进行疏水改性,根据改性方式可以将水泥基材料的超疏水改性分为表面超疏水改性和整体超疏水改性,表面超疏水改性是通过在混凝土表面的孔壁上附着疏水剂实现,形成连续的保护层以增强混凝土凝结硬化后的耐久性;整体超疏水改性通常将疏水混合物与水泥基材料融合,从而实现水泥基材料的整体超疏水改性。评价超疏水改性效果,可以通过检测水泥基材料的水接触角(WCA)、滚动角(SA),当满足150˚ < CA < 180˚,同时SA < 10˚时,认为材料具备超疏水性能。

2.1. 表面超疏水改性

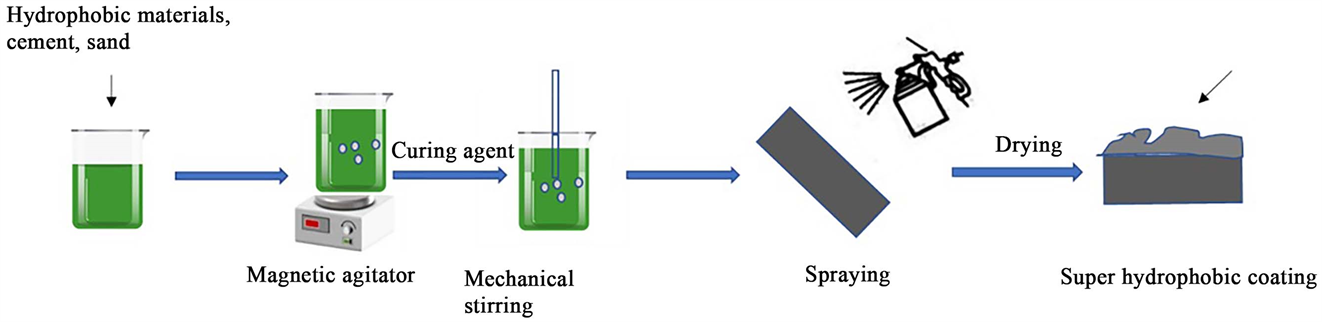

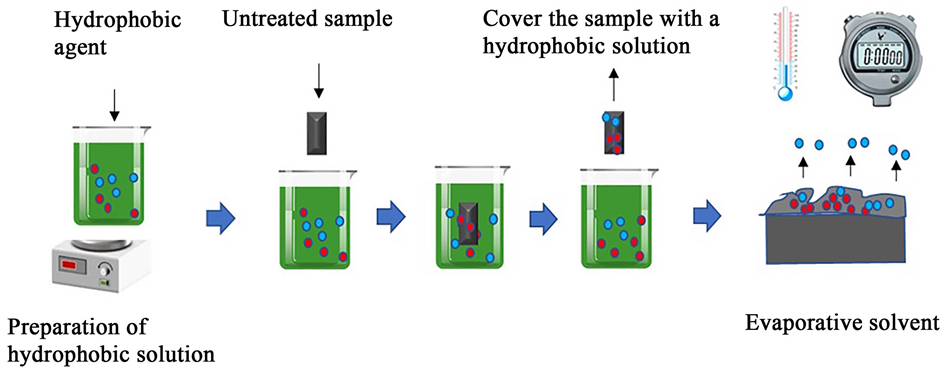

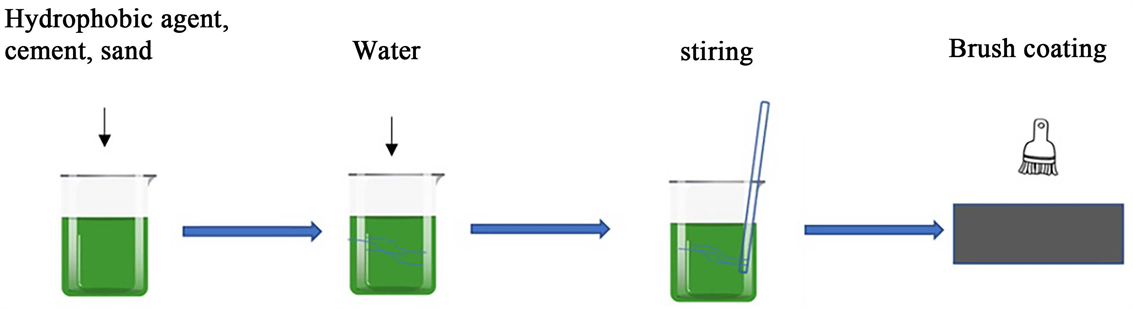

总结近年来混凝土表面超疏水改性的研究 [8] [9] ,表面超疏水改性可以归纳为以下三种主要类型:1)喷涂 [10] :通过喷涂在表面沉积富含微纳米颗粒的疏水悬浮液,如图1所示;2) 浸渍 [11] :将样品浸入含有纳米颗粒的疏水性有机溶液或水乳液中,如图2所示;3) 刷涂 [12] :通过刷涂将聚合物和水泥浆体覆盖在混凝土表面,如图3所示。

从生产工艺来看,表面超疏水改性主要通过喷涂、刷涂和浸渍三种方式实现,工艺简单、操作灵活,适应性强,可以根据具体的应用场景采用不同的疏水剂和纳米材料。但表面改性存在明显的缺点:涂层与固体表面之间的粘合强度低、涂层易开裂、表面改性水泥基材料无法保证长期耐久性(有机硅烷分子与混凝土表面之间的化学键长时间暴露在水中会被降解) [13] 。所以考虑表明超疏水改性前要做好充分的表面评估和准备,否则容易出现疏水材料与水泥基材料粘结力不足、疏水材料浸渍深度不够、水泥基材料表面形态不满足疏水条件等情况。

Figure 1. Preparation process diagram of superhydrophobic spraying

图1. 超疏水喷涂制备工艺示意图

Figure 2. Preparation process diagram of superhydrophobic coating impregnation

图2. 超疏水涂层浸渍制备工艺示意图

Figure 3. Preparation process diagram of superhydrophobic brush coating

图3. 超疏水刷涂制备工艺示意图

2.2. 超疏水整体改性

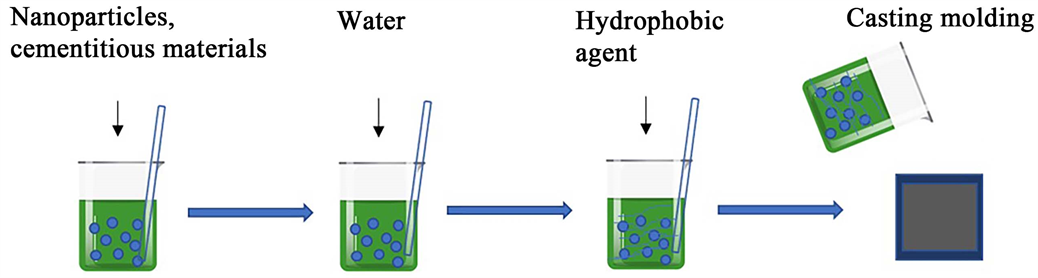

针对混凝土开裂、涂层老化和剥落使得新暴露出来的结构显示原来的亲水性问题,表面改性难以解决。在这种情况下研究人员提出了在水泥基材料成型过程中添加疏水材料,即所谓的整体改性,其制备工艺如图4所示。整体超疏水改性所制得的混凝土在表层脱落或破坏时通过简单的表面研磨处理即可恢复超疏水性能,整体超疏水改性方式包括:直接掺加疏水剂 [14] [15] [16] [17] 和使用经疏水改性的胶凝材料 [18] ,这两种方式受外界的影响小,但造价成本较高。

3. 超疏水改性剂

目前水泥基材料超疏水改性所用的改性剂有很多,改性剂配合不同制备工艺改性效果各有不同,在两种超疏水改性方式中,常用的疏水剂包括硅烷、硅氧烷、硬脂酸等,常用构造粗糙度的纳米级颗粒有二氧化硅、偏高岭土 [19] 、硅藻土等纳米颗粒。下面对常用的疏水改性剂(硅烷和硅氧烷、硬脂酸)和二氧化硅纳米颗粒进行详细介绍。

Figure 4. Schematic diagram of the overall superhydrophobic preparation process

图4. 整体超疏水制备工艺示意图

硅烷和硅氧烷凭借其小分子结构特点,可以渗透到水泥基材料致密结构中,通过与胶凝材料发生反应进而对水泥基材进行疏水改性 [20] 。由于聚二甲基硅氧烷(PDMS)优异的化学惰性、无毒、成本适中、生物相容性和环境友好性而经常用于制备超疏水混凝土,相关综述总结了PDMS的其他显著优势 [9] :1) PDMS含有柔性Si-O-Si骨架,能够适当抵挡外部冲击;2) PDMS的低粘度使改性基材具有更好的抗渗性;3) PDMS分子的–OH基团与无机材料发生的水解缩合反应使得PDMS能更好键合在水泥基材上。硅烷和聚二甲基硅氧烷因以上优异性能,用作疏水改性剂深受研究人员喜爱,表1总结了近几年硅烷和硅氧烷用于水泥基材料疏水改性。

Table 1. Silane and siloxane used for hydrophobic modification of cement materials

表1. 硅烷和硅氧烷用于水泥材料疏水改性

硬脂酸(STA)分子中的羧基可以接枝到水泥基材料的羟基上形成长链烷基,长链烷基可以显著降低表面能,所以硬脂酸是一种超疏水性改性的常用材料 [26] [27] [28] 。Charikleia等人 [29] 通过使用硬脂酸和造纸污泥制备超疏水粉末,通过研究不同链长的脂肪酸得出硬脂酸产生的疏水性最高。此后,大量学者将硬脂酸用于水泥基材料的超疏水改性,Wang [30] 通过将水泥石样品浸入STA溶液中,采用简单的浸渍法制得超疏水水泥石(SCS)。Lei [31] 采用STA和铜网制备超疏水混凝土,探明了在STA含量为0.8 g时,超疏水混凝土CA和SA分别达到159˚和5˚的最优值。其中,STA主要通过与混凝土中的羟基接枝,形成疏水尾链;此外,水泥水化产物再进一步与STA反应生成硬脂酸钙,增加了额外的粗糙度。表2总结了近几年硬脂酸用于水泥基材料疏水改性。

Table 2. Stearic acid used for hydrophobic modification of cement materials

表2. 硬脂酸用于水泥材料疏水改性

纳米级颗粒用于水泥基材料超疏水改性不仅能够构建表面微纳米级粗糙结构,还能细化水泥基材料内部孔隙,提高水泥基材料抗渗性能。其中,纳米二氧化硅(NS)因其化学稳定性、易于制备和大小可控的优点被广泛使用。NS的加入可以降低水泥水化物在表层区域的Ca/Si比,随着Ca/Si比的降低,硅酸钙水合物(C-S-H)凝胶的刚度和内聚强度可以显著提高 [34] 。此外,通过在改性水泥基材料的过程中掺入NS可以解决硅烷超疏水改性水化延缓和强度降低的问题,研究表明,二氧化硅纳米颗粒附着在混凝土表面,形成微纳米级粗糙结构,创造了超疏水改性条件;其次,火山灰效应与水泥水化产物C-S-H凝胶反应堵塞混凝土孔隙,降低吸水率提高水泥基材料力学性能 [17] 。特别的,纳米二氧化硅掺入超疏水泡沫混凝土可以起到稳定气泡的作用 [25] ,机理如图5所示。表3总结了近几年纳米二氧化硅用于水泥基材料超疏水改性。

Figure 5. Construction diagram of porous hydrophobic interface of foamed concrete [25]

图5. 泡沫混凝土孔隙疏水界面构建示意图

Table 3. Nano silica used for hydrophobic modification of cement materials

表3. 纳米二氧化硅用于水泥材料疏水改性

4. 结语

超疏水水泥基材料的应用提高了结构的耐久性,有利于提高混凝土建筑物的使用寿命,减少了后期的维护成本和可能存在的内在隐患。本文介绍了水泥基材料超疏水改性方式、疏水改性材料,并得出以下结论:

1) 水泥基材料的表面超疏水改性和整体超疏水改性均能提高水泥基材料的疏水性能。

2) 一般表面超疏水改性和整体超疏水改性选用的疏水剂不同,但大多采用硅烷、硅氧烷、硬脂酸、二氧化硅纳米颗粒等,其中不同的疏水剂使水泥基材料附带的性能各异。

上述结论可以为超疏水改性水泥基材料提供一定的借鉴和参考,接下来可以继续从以下几个方面开展深入研究:

1) 整体超疏水改性中,超疏水改性剂的直接掺入,或经超疏水改性的骨料的掺入是否会对水泥基材料流变性能产生影响,目前相关文献对这一研究较少涉及。

2) 有没有其他材料可以代替现有的硅烷及硅氧烷一类材料,降低超疏水泡沫混凝土的制造成本,可以展开进一步的研究。

文章引用

姚 铃. 水泥基材料超疏水改性方式以及改性材料

Superhydrophobic Modification of Cement-Based Materials and Modified Materials[J]. 土木工程, 2023, 12(07): 941-948. https://doi.org/10.12677/HJCE.2023.127107

参考文献

- 1. 郑元勋, 杨培冰, 康海贵. 冻融环境下混凝土结构耐久性研究综述[J]. 郑州大学学报(工学版), 2016, 37(5): 27-32.

- 2. 鲁浈浈, 何杨, 王杰, 等. 环氧树脂/SiO2涂层混凝土表面主动抗凝冰性及除冰性能研究[J]. 表面技术, 2020, 49(10): 169-175.

- 3. 王志博, 牛志强. 超疏水材料涂层对混凝土抗冻性能的影响[J]. 新型建筑材料, 2017, 44(2): 107-110.

- 4. Zhao, Z.G., Qu, X.L. and Li, J.H. (2020) Application of Polymer Modified Cementitious Coatings (PCCs) for Impermeability Enhancement of Concrete. Construction & Building Materials, 249, Article ID: 118769.

https://doi.org/10.1016/j.conbuildmat.2020.118769 - 5. 廖圣炜, 武念铎, 卢俊杰, 等. 超高性能混凝土的制备与性能综述[C]//第二十二届现代结构工程学术研讨会. 第二十二届现代结构工程学术研讨会论文集. 徐州: 中国钢结构协会, 中国建筑金属结构协会, 天津市科学技术协会, 天津大学, 2022: 304-309.

- 6. Barthlott, W. and Neinhuis, C. (1997) Purity of the Sacred Lotus, or Escape from Contamination in Biological Surfaces. Planta, 202, 1-8.

https://doi.org/10.1007/s004250050096 - 7. Neinhuis, C. and Barthlott, W. (1997) Characterization and Distribution of Water-Repellent, Self-Cleaning Plant Surfaces. Annals of Botany, 79, 667-677.

https://doi.org/10.1006/anbo.1997.0400 - 8. Pan, X., Shi, Z., Shi, C., Ling, T.C. and Li, N. (2017) A Review on Concrete Surface Treatment Part I: Types and Mechanisms. Construction and Building Materials, 132, 578-590.

https://doi.org/10.1016/j.conbuildmat.2016.12.025 - 9. Wu, Y., Dong, L., Shu, X., et al. (2022) A Review on Recent Advances in the Fabrication and Evaluation of Superhydrophobic Concrete. Composites Part B: Engineering, 237, Article ID: 109867.

https://doi.org/10.1016/j.compositesb.2022.109867 - 10. 余德密. 无氟超疏水涂层在混凝土表面的仿生构建及其应用研究[D]: [硕士学位论文]. 杭州: 浙江大学, 2022.

- 11. 于梅. 环保型超疏水混凝土制备工艺优化及其在渠道衬砌工程中的应用[J]. 水利科学与寒区工程, 2021, 4(3): 94-96.

- 12. Yin, B., et al. (2022) Superhydrophobic Coatings Based on Bionic Mineralization for Improving the Durability of Marine Concrete. Construction and Building Materials, 362, Article ID: 129705.

https://doi.org/10.1016/j.conbuildmat.2022.129705 - 13. Wang, P., Yang, Y., Wang, H.B. and Wang, H.Q. (2019) Fabrication of Super-Robust and Nonfluorinated Superhydrophobic Coating Based on Diatomaceous Earth. Surface & Coatings Technology, 362, 90-96.

https://doi.org/10.1016/j.surfcoat.2019.01.065 - 14. Wei, Q., Liu, X. and Zhang, X. (2018) Facile Preparation of Mechanically Robust Superhydrophobic Concrete with Self-Cleaning Property. Materials Research Express, 6, Article ID: 015001.

https://doi.org/10.1088/2053-1591/aae2a6 - 15. Shen, C., Zhu, Y., Shi, W., et al. (2020) Mechanically Stable Superhydrophobic Surface on Cement-Based Materials. Chemical Physics, 538, Article ID: 110912.

https://doi.org/10.1016/j.chemphys.2020.110912 - 16. She, W., Zheng, Z., Zhang, Q., et al. (2020) Predesigning Matrix-Directed Super-Hydrophobization and Hierarchical Strengthening of Cement Foam. Cement and Concrete Research, 131, Article ID: 106029.

https://doi.org/10.1016/j.cemconres.2020.106029 - 17. Yang, J.X., She, W., Zuo, W.Q., Lyu, K. and Zhang, Q.C. (2021) Rational Application of Nano-SiO2 in Cement Paste Incorporated with Silane: Counterbalancing and Synergistic Effects. Cement & Concrete Composites, 118, Article ID: 103959.

https://doi.org/10.1016/j.cemconcomp.2021.103959 - 18. Qu, Z.Y., Alam, Q., Gauvin, F., et al. (2020) Development of Water-Resisting Mortar by Incorporation of Functionalized Waste Incineration Ashes. Journal of Cleaner Production, 249, Article ID: 119341.

https://doi.org/10.1016/j.jclepro.2019.119341 - 19. Flores-Vivian, I., Hejazi, V., Kozhukhova, M.I., et al. (2013) Self-Assembling Particle-Siloxane Coatings for Superhydrophobic Concrete. ACS Applied Materials & Interfaces, 5, 13284-13294.

https://doi.org/10.1021/am404272v - 20. Sakr, M.R. and Bassuoni, M.T. (2021) Silane and Methyl-Methacrylate Based Nanocomposites as Coatings for Concrete Exposed to Salt Solutions and Cyclic Environments. Cement & Concrete Composites, 115, Article ID: 103841.

https://doi.org/10.1016/j.cemconcomp.2020.103841 - 21. She, W., Wang, X., Miao, C., et al. (2018) Biomimetic Superhydrophobic Surface of Concrete: Topographic and Chemical Modification Assembly by Direct Spray. Construction & Building Materials, 181, 347-357.

https://doi.org/10.1016/j.conbuildmat.2018.06.063 - 22. Cheng, H., Wang, F., Ou, J., et al. (2021) Solar Reflective Coatings with Luminescence and Self-Cleaning Function. Surfaces and Interfaces, 26, Article ID: 101325.

https://doi.org/10.1016/j.surfin.2021.101325 - 23. Horgnies, M. and Chen, J.J. (2014) Superhydrophobic Concrete Surfaces with Integrated Microtexture. Cement & Concrete Composites, 52, 81-90.

https://doi.org/10.1016/j.cemconcomp.2014.05.010 - 24. Li, K., Wang, Y., Wang, X., et al. (2021) Superhydrophobic Magnesium Oxychloride Cement Based Composites with Integral Stability and Recyclability. Cement & Concrete Composites, 118, Article ID: 103973.

https://doi.org/10.1016/j.cemconcomp.2021.103973 - 25. Sun, L., Xu, Y.D., Wang, J.L., Wang, R. and Yao, L. (2023) Designing a Superhydrophobic Quality and Strengthening Mechanism for Foam Concrete. Construction & Building Materials, 365, Article ID: 130073.

https://doi.org/10.1016/j.conbuildmat.2022.130073 - 26. Feng, Y.C., Chen, S.G. and Cheng, Y.F. (2018) Stearic Acid Modified Zinc Nano-Coatings with Superhydrophobicity and Enhanced Antifouling Performance. Surface & Coatings Technology, 340, 55-65.

https://doi.org/10.1016/j.surfcoat.2018.02.053 - 27. Cao, Z.F., Lu, F., Qiu, P., et al. (2018) Formation of a Hydrophobic and Corrosion Resistant Coating on Manganese Surface via Stearic Acid and Oleic Acid Diethanolamide. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 555, 372-380.

https://doi.org/10.1016/j.colsurfa.2018.07.020 - 28. Xu, S.S., Wang, Q., Wang, N. and Zheng, X. (2019) Fabrication of Superhydrophobic Green Surfaces with Good Self-Cleaning, Chemical Stability and Anti-Corrosion Properties. Journal of Materials Science, 54, 13006-13016.

https://doi.org/10.1007/s10853-019-03789-x - 29. Spathi, C., Young, N., Heng, J.Y.Y., Vandeperre, L.J.M. and Cheeseman, C.R. (2015) A Simple Method for Preparing Super-Hydrophobic Powder from Paper Sludge Ash. Materials Letters, 142, 80-83.

https://doi.org/10.1016/j.matlet.2014.11.123 - 30. Wang, F.J., Zhang, M.G., Lei, S., Ou, J.F. and Li, W. (2019) Rapid Preparation of Superhydrophobic Surface on Cement Stone. Applied Physics A, 125, Article No. 386.

https://doi.org/10.1007/s00339-019-2685-7 - 31. Lei, L.L., Wang, Q., Xu, S.S. and Wang, N. and Zheng, X. (2020) Fabrication of Superhydrophobic Concrete Used in Marine Environment with Anti-Corrosion and Stable Mechanical Properties. Construction & Building Materials, 251, Article ID: 118946.

https://doi.org/10.1016/j.conbuildmat.2020.118946 - 32. Qu, Z.Y. and Y,u Q.L. (2018) Synthesizing Super-Hydrophobic Ground Granulated Blast Furnace Slag to Enhance the Transport Property of Lightweight Aggregate Concrete. Construction & Building Materials, 191, 176-186.

https://doi.org/10.1016/j.conbuildmat.2018.10.018 - 33. Zhu, J. and Liao, K. (2020) A Facile and Low-Cost Method for Preparing Robust Superhydrophobic Cement Block. Materials Chemistry and Physics, 250, Article ID: 123064.

https://doi.org/10.1016/j.matchemphys.2020.123064 - 34. Karthick, S., Park, D., Lee, Y.S., et al. (2018) Development of Water-Repellent Cement Mortar Using Silane Enriched with Nanomaterials. Progress in Organic Coatings, 125, 48-60.

https://doi.org/10.1016/j.porgcoat.2018.08.021 - 35. Gao, Y., Qu, L., He, B., et al. (2018) Study on Effectiveness of Anti-Icing and Deicing Performance of Super-Hydro- phobic Asphalt Concrete. Construction & Building Materials, 191, 270-280.

https://doi.org/10.1016/j.conbuildmat.2018.10.009 - 36. Zhao, Y., Liu, Y., Liu, Q., et al. (2018) Icephobicity Studies of Superhydrophobic Coatings on Concrete via Spray Method. Materials Letters, 233, 263-266.

https://doi.org/10.1016/j.matlet.2018.09.008 - 37. Husni, H., Nazari, M.R., Yee, H.M., et al. (2017) Superhydrophobic Rice Husk Ash Coating on Concrete. Construction & Building Materials, 144, 385-391.

https://doi.org/10.1016/j.conbuildmat.2017.03.078 - 38. Facio, D.S. and Mosquera, M.J. (2013) Simple Strategy for Producing Superhydrophobic Nanocomposite Coatings in situ on a Building Substrate. ACS Applied Materials & Interfaces, 5, 7517-7526.

https://doi.org/10.1021/am401826g