Hans Journal of Chemical Engineering and Technology

Vol.07 No.06(2017), Article ID:22895,14

pages

10.12677/HJCET.2017.76042

Innovation in Layer-by-Layer Self-Assembly Technology

Ben Fei1,2, Yijing Jiang1,2, Sha Lin1,2, Qing Shen1,2*

1State Key Laboratory for Modification of Chemical Fiber and Polymer Materials, Donghua University, Shanghai

2Polymer Department of Donghua University, Shanghai

*通讯作者。

Received: Nov. 10th, 2017; accepted: Nov. 23rd, 2017; published: Nov. 30th, 2017

ABSTRACT

The application of Layer-by-Layer self-assembly in the preparation of nanomaterials has been paid more and more attention, which has promoted the development of material preparation methods. Based on the continuous emergence of new technologies for Layer-by-Layer self-assembly, this paper summarizes the recent developments in this technology.

Keywords:Self-Assembly, Spray, Fluid, Electricity, Magnetics

层层自组装技术的新进展

费奔1,2,江依静1,2,林莎1,2,沈青1,2*

1东华大学纤维材料改性国家重点实验室,上海

2东华大学高分子系,上海

收稿日期:2017年11月10日;录用日期:2017年11月23日;发布日期:2017年11月30日

摘 要

层层自组装技术在纳米材料制备过程的应用受到了日益增长的关注、推动了材料制备方法的发展。基于层层自组装新技术的不断涌现,本文对该技术在最近的发展进行了综述。

关键词 :自组装,喷雾,流体,电,磁

Copyright © 2017 by authors and Hans Publishers Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

1. 简介

层层自组装技术是一项给基体覆盖上聚合物、胶体、生物分子和细胞等物质从而形成多层微纳米结构的技术,自发明以来已经有了许多研究和应用 [1] - [9] 。不同于传统的层层自组装技术通过有序地吸附材料的相反电荷(通过向焓和熵的驱动力)形成新型材料结构,我们关注到近来一些新型的自组装技术的发明似乎进一步推动了该技术的研究与应用,并引发了人们的关注 [10] [11] [12] 。

2. 高重力旋转自组装

旋转自组装的方法就是使用旋转力使聚合物或其他溶液形成胶体分散体系并层层自组装的过程。相比于普通的层层自组装基体垂直于旋转轴,它的基体平行于旋转轴如图1所示 [13] 。由于这个过程在平面或非平面体上产生了很高的离心力,所以被叫做高重力旋转自组装 [14] 。这种方法适用于较低浓度聚合物的自组装,有利于使得自组装胶体和微粒的沉积更快更均匀 [15] 。高重力自组装一般是线性的 [16] 。长时间的高重力旋转自组装可以使聚合物完全解吸,而不像其他的LbL技术只是部分解吸 [17] 。

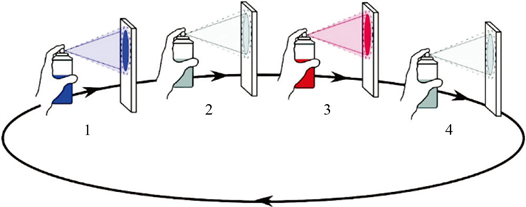

3. 喷雾自组装

涂布材料在日常生活、工业和研究中随处可见。而喷雾自组装实质上是一种涂层技术,适用于干燥定向膜 [18] 、多层膜 [19] 。目前大型喷雾自组装 [17] 已经工业化了 [21] ,类似于洗车设备如图2所示 [20] [21] [22] [23] 。

3.1. 人工喷雾自组装

通过比较传统浸渍和顺序喷雾来制作聚(苯乙烯磺酸)/聚(烯丙胺盐酸盐)(PSS/PAH)的多层膜,两者具有相似的特性但是喷雾自组装要更快,所以喷雾自组装要普通LbL技术有优势 [24] 。一般说来,薄膜通过喷聚合物溶液在基体上然后在基体上喷水来除去多余的未结合的聚合物(图3) [24] [25] [26] 。

影响人工喷雾自组装的主要因素是聚合物浓度、喷雾时间、流速、喷雾方向:比如是垂直或水平喷射 [24] [25] [26] 。喷雾自组装也可用于涂覆塑料外形等大型非平面基体,也可以用于自组装金属薄膜而不需要电沉积 [27] 。喷雾自组装在科技创新上仍有较好的势头,它也能带来现有技术的整合。

3.2. 旋转喷雾自组装

喷雾自组装已经跟其它一些技术结合来解决单一喷雾自组装过程所遇到的问题。比如,重力流动和喷嘴效应等导致的薄膜不均一性 [28] 。目前这些问题主要通过控制旋转来解决(图4) [29] - [34] 。

旋转喷雾自组装不仅能够减少材料的损失,而且可以使材料溶液浓度较普通的自组装低10~50倍 [30] [34] 。这种方法还可以使蛋白质类的生物大分子相比于普通方法更容易获得不同的二级结构 [35] 及工业化和自动化 [36] 。

Figure 1. Schematic illustration of high gravity rotation self-assembly of polymer solution

图1. 聚合物溶液的高重力旋转自组装示意图

Figure 2. Spray LbL self-assembly process is similar to a car wash process

图2. 喷雾自组装的过程类似于一个洗车过程

Figure 3. Schematic illustration of manual spray self-assembly

图3. 人工喷雾自组装示意图

Figure 4. Schematic illustration of spin-spray assembly

图4. 旋转喷雾自组装示意图

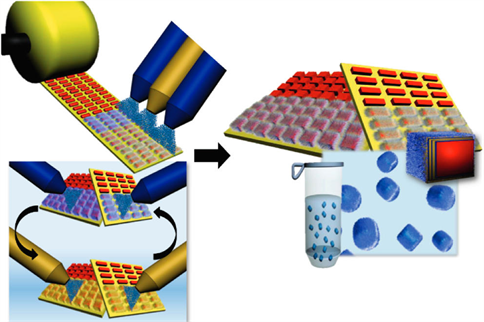

3.3. 自动喷雾自组装

虽然人工喷雾自组装比浸渍自组装有了很大的提高,但是它仍需要人工干预和手工作业,为此自动喷雾自组装体系被发展起来 [31] ,并已经被成功应用到制备管式薄膜 [37] 。此外,自动喷雾自组装也可以通过QCM来监视和控制,使用一个反馈回路来实时追踪薄膜的生长 [38] 。在此情况下,喷嘴需要和基体扫描方向平行来获得均匀的平面薄膜,并通过调节喷雾压力改变薄膜厚度。最近发明的卷轴式自动喷雾自组装技术可以应用于生产大型基体(图5) [39] 。这种方法叶被称为打印方法 [40] 。

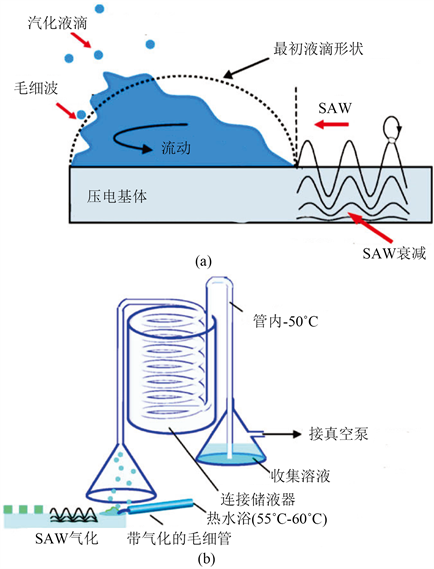

3.4. 多层颗粒喷雾自组装

喷雾自组装的另一使用就是在涂布材料被喷洒或雾化的时候形成涂布纳米颗粒。该方法使用超声波来雾化液滴,使得溶剂从聚合物溶液中蒸发,从而导致聚合物溶液浓缩在纳米颗粒上,形成涂布效果(图6) [41] 。

4. 自动化流体自组装

基于液体流动的自动自组装被称为自动化流体自组装可以使用流体通道或毛细管来沉积形成多层膜 [42] [43] 。一般的聚合物都可以通过溶解形成溶液并应用这种方法形成多层膜 [44] [45] 。这种方法有利于人工涂布微管道 [46] ,并可以应用泵将高分子溶液注入微管道中、然后通过真空去除溶液 [47] 。

4.1. 流体自动自组装

使用复杂的微流体设备并通过毛细作用和真空清空通道可以在基体表面自组装成膜如图7所示 [48] 。在这种情况下,只需要应用少量的材料(液滴)便可以填充微通道。但该方法需要应用真空和泵等辅助设备 [49] 。

Figure 5. Schematic illustration of roll-to-roll spray assembly

图5. 卷轴式自动喷雾自组装示意图

Figure 6. Schematic illustration of multilayer-generating spray assembly (a) The piezoelectric substrate produces micrometer-sized aerosol droplets. (b) Schematic illustration of the experimental setup

图6. 多层颗粒喷雾自组装示意图,(a) 压电基体产生微米级的雾化液滴;(b) 试验装置示意图

Figure 7. (a) Schematic illustrations of the automated fluidic assembly process. (b) Photograph of the actual fluidic chamber

图7. (a) 自动化流体自组装过程示意图。(b) 实际流体室照片

4.2. 流体真空自组装

真空与其他流体方法结合也能够形成独特的多层膜如图8所示 [50] 。这个方法适用于导电高分子、生物材料和碳纳米管,也可用来防止石墨被氧化 [51] 。

4.3. 颗粒基体的流体自组装

颗粒基体的流体自组装过程一般使用微流体设备 [52] [53] [54] [55] [56] 。图9描述了这种方法,其中洗涤溶液的流动方向垂直于聚电解质颗粒液流 [57] 。通过调节流体和聚电解质的电荷可以控制自组装的过程 [58] 。

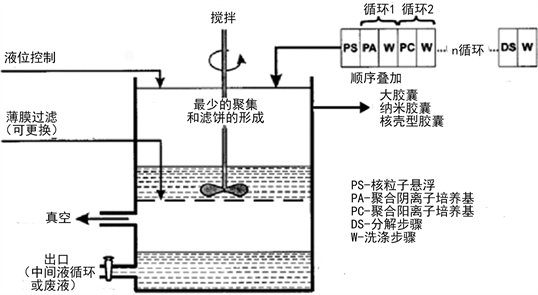

4.4. 颗粒基体的过滤自组装

除了复杂的微流体以外,颗粒基体的流体自组装也能通过物理方法分离-即过滤来实现(图10) [59] 。在这个方法中,固体颗粒和脂质体被泵入切向流动的过滤系统中,当流过过滤器的时候聚合物会迅速透析出流体管道然后进行自组装 [60] [61] 。这个方法不适用于红细胞等比较敏感的材料 [62] 。

Figure 8. Schematic illustration of vacuum-assisted assembly

图8. 真空辅助自组装示意图

Figure 9. (a) Schematic illustration of fluidic assembly. (b) Magnified schematic from (a). (c) Microscopy images of the droplets moving through the coating and washing solutions

图9. (a) 颗粒基体的流体自组装示意图,(b) 放大的示意图,(c) 液滴运动的显微镜图像

Figure 10. Schematic illustration of fluidic assembly

图10. 颗粒基体的流体自组装示意图

5. 电强制组装

基于外部电场推动的自组装事实上是一种非自组装,即电场强制进行的组装。这种方法特别适用于磁性材料的组装 [63] [64] [65] [66] 。

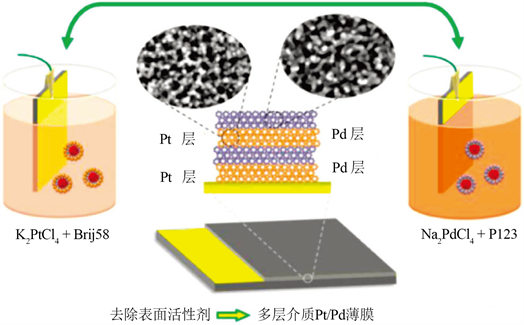

电组装过程可以沉积金属以及可以用来形成双金属介孔硅/氧化硅多层膜(图11) [66] 。

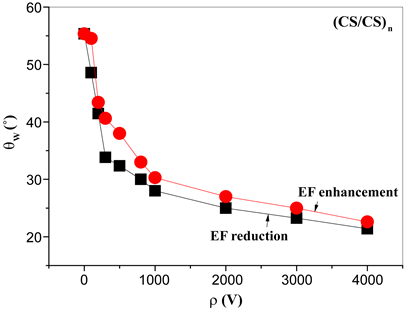

电组装方法也适合高分子、酶、胶体和混合材料;但在操作过程电极的极性通常会发生转变或减小 [66] - [72] 。另外,将基体放置在电极之间而不改变电极极性的电组装技术也已经实现,使得高分子可以从任意一端进行组装 [73] [74] 。此外,这种方法也使用了高的电压 [75] 。对于在一个电极上进行的电组装来说,如果此时聚合物带有充足的电荷则高的电压会导致薄膜变厚,但当电压高于一个特定值时会使得薄膜厚度开始减小,原因是此时电极/基体排斥先前组装的层片而导致了解吸 [76] 。此外,如果薄膜变得过厚时,由于无法产生充足的电流,所以薄膜的生长也就停止了 [77] 。

电组装方法可以促进材料的溶胶-凝胶转变 [77] ,有利于一些功能单元如卟啉、富勒烯和氟被组装到单组分或多组分的薄膜中,或使用N-烷基咔唑的衍生物通过耦合反应来形成C-C键 [78] [79] [80] 。

近来,我们应用静电发生器对一系列高分子材料进行了电组装如图12所示。不同于上面所介绍的电组装方法,我们的实验发现具有正电荷的壳聚糖与具有负电荷的木质素磺酸盐进行层层交替电组装得到的表面润湿性可以通过调控静电引力(EF)而从亲水性变成疏水性 [81] ,而壳聚糖层层独立电组装得到的表面却可以在静电引力调控下加强其亲水性如图13所示 [82] 。

由此可知,电组装技术正在不断地发展中,而普通的电组装技术的唯一依赖是调控电压,而我们发明的新型电组装技术则不仅可以调控电压、还可以调控有静电引力,即具有两种调控模式。

事实上,我们还进一步发现,这种静电调控的电组装技术具有使材料内部的亲水或疏水官能团迁移到表面的能力,而这种官能团的选择性则取决于静电引力的加强或减弱对材料极性的影响。

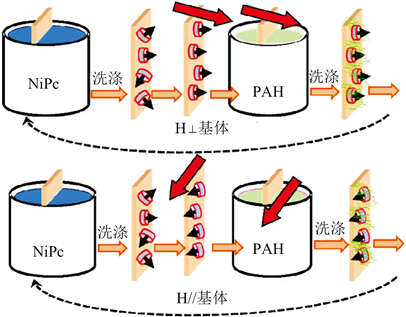

6. 磁强制组装

用磁力和磁场来代替电流也能够加快自组装和修改多层薄膜。磁性纳米颗粒在磁场下沉积可以得到高密度的薄膜 [67] 。在外部磁场的作用下,磁性小分子可以在多层膜中被定位 [83] 。有趣的是,磁场的位置(垂直或者平行)在最后薄膜自组装磁性材料的形态上起到了重要作用(图14) [84] 。具体来说,平行定位

Figure 11. Schematic illustration of simple LbL electrodeposition

图11. 电组装示意图

Figure 12. Schematic diagram of electrostatic attraction control during electrical assembly

图12. 电组装过程静电引力控制示意图

Figure 13. Effect of voltage and electrostatic attraction (EF) on the surface wettability of the assembly process of chitosan

图13. 壳聚糖层层电组装过程电压及静电引力(EF)控制对表面润湿性的影响

Figure 14. Schematic diagram of magnetic assembly

图14. 磁组装示意图

的磁场一般导致密集的自组装和更大的层片厚度,而且由于磁场线会导致条纹状薄膜。当用小分子制作晶体的时候,它们的磁矩在平行或垂直的磁场下自组装时也被设计成朝向特定的方向 [85] 。王等人 [86] 在近平行方向磁场作用下,以纳米Fe3O4为磁组装对象在氟碳树脂体系中制备出有序平行线形阵列结构磁组装薄膜材料。叶等人 [87] 在强磁场中得到了具有较高表面能及较高极性分量的自组装分子膜。

磁铁在定位自组装材料时不受限制,反而可以用来从涂层材料中分离基体从而避免离心步骤 [87] [88] [89] 。

7. 小结

自组装技术的实用性已经是被无数实验和应用所证明的一个无容置疑的事实,因而该技术的任何新进展都无疑将进一步促进科学技术的发展、从而造福于人类。因此,可以相信本文所综述到的一些自组装新技术、新方法将帮助广大科技人员了解这方面的最新进展。

文章引用

费奔,江依静,林莎,沈青. 层层自组装技术的新进展

Innovation in Layer-by-Layer Self-Assembly Technology[J]. 化学工程与技术, 2017, 07(06): 301-314. http://dx.doi.org/10.12677/HJCET.2017.76042

参考文献 (References)

- 1. Richardson, J.J., Björnmalm, M. and Caruso, F. (2015) Multilayer Assembly. Technology-Driven Layer-by-Layer Assembly of Nanofilms. Science, 348, 2491.

- 2. Decher, G. and Schlenoff, J.B. (2012) Multilayer Thin Films: Sequential Assembly of Nanocomposite Materials. 2nd Edition, Wiley-VCH, Weinheim, Germany. https://doi.org/10.1002/9783527646746

- 3. Peiffre, D., Corley, T., Halpern, G., et al. (1981) Utilization of Polymeric Materials in Laser Fusion Target Fabrication. Polymer, 22, 450-460. https://doi.org/10.1016/0032-3861(81)90159-2

- 4. Fujita, S. and Shiratori, S. (2004) Waterproof Anti Reflection Films Fabricated by Layer-by-Layer Adsorption Process. Japanese Journal of Applied Physics, 43, 2346-2351. https://doi.org/10.1143/JJAP.43.2346

- 5. Kim, J.H., Kim, S.H. and Shiratori, S. (2004) Electrospun Nanofibrous Membranes Coated Quartz Crystal Microbalance as Gas Sensor for NH 3 Detection. Actuators, 102, 241-247.

- 6. Decher, G. (1997) Toward Layered Polymeric Multicomposites. Science, 277, 1232-1237. https://doi.org/10.1126/science.277.5330.1232

- 7. Decher, G., Hong, J. and Schmitt, J. (1992) Buildup of Ultrathin Multilayer Films by a Self-Assembly Process: III. Consecutively Alternating Adsorption of Anionic and Cationic Polyelectrolytes on Charged Surfaces. Thin Solid Films, 210, 831-835. https://doi.org/10.1016/0040-6090(92)90417-A

- 8. Decher, G. and Hong, J.D. (1991) Layer-by-Layer Deposited Multilayer Assemblies of Polyelectrolytes and Proteins: From Ultrathin Films to Protein Arrays. Macromolecular. Symposia, 46, 321-327. https://doi.org/10.1002/masy.19910460145

- 9. Decher, G. and Hong, J. (1991) Buildup of Ultrathin Multilayer Films by a Self-Assembly Process: II. Consecutive Adsorption of Anionic and Cationic Bipolar Amphiphiles and Polyelectrolytes on Charged Surfaces. Berichte der Bunsengesellschaft für Physikalische Chemie, 95, 1430-1434. https://doi.org/10.1002/bbpc.19910951122

- 10. Fu, J. and Schlenoff, J.B. (2016) Driving Forces for Oppositely Charged Polyion Association in Aqueous Solutions: Enthalpic, Entropic, but Not Electrostatic. Journal of the American Chemical Society, 138, 980-990. https://doi.org/10.1021/jacs.5b11878

- 11. Borges, J. and Mano, J.F. (2014) Molecular Interactions Driving the Layer-by-Layer Assembly of Multilayers. Chemical Reviews, 114, 8883-8942. https://doi.org/10.1021/cr400531v

- 12. Zhang, X., Chen, H. and Zhang, H. (2007) Layer-by-Layer Assembly: From Conventional to Unconventional Methods. Chemical Communications, 1395-1405. https://doi.org/10.1039/B615590A

- 13. Ma, L., Cheng, M., Jia, G., et al. (2012) Layer-by-Layer Self-Assembly under High Gravity Field. Langmuir, 28, 9849-9856. https://doi.org/10.1021/la301553w

- 14. Costa, R.R. and Mano, J.F. (2014) Polyelectrolyte Multilayered Assemblies in Biomedical Technologies. Chemical Society Reviews, 43, 3453-3479. https://doi.org/10.1039/c3cs60393h

- 15. Boudou, T., Crouzier, T., Ren, K., et al. (2010) Multiple Functionalities of Polyelectrolyte Multilayer Films: New Biomedical Applications. Advanced Materials, 22, 441-467. https://doi.org/10.1002/adma.200901327

- 16. Saha, S. and Loo, S.C.J.J. (2015) Recent Developments in Multilayered Polymeric Particles—From Fabrication Techniques to Therapeutic Formulations. Journal of Materials Chemistry. B, 3, 3406-3419. https://doi.org/10.1002/adma.200901327

- 17. Correa, S., Dreaden, E.C., Gu, L., et al. (2016) Engineering Nanolayered Particles for Modular Drug Delivery. Journal of Controlled Release, 240, 364-386. https://doi.org/10.1016/j.jconrel.2016.01.040

- 18. De Koker, S., Hoogenboom, R. and De Geest, B.G. (2012) Polymeric Multilayer Capsules for Drug Delivery. Chemical Society Reviews, 41, 2867-2884. https://doi.org/10.1039/c2cs15296g

- 19. Ariga, K., Lvov, Y.M., Kawakami, K., et al. (2011) Layer-by-Layer Self-Assembled Shells for Drug Delivery. Advanced Drug Delivery Reviews, 63, 762-771. https://doi.org/10.1016/j.addr.2011.03.016

- 20. Ariga, K., Yamauchi, Y., Rydzek, G., et al. (2014) ChemInform Abstract: Layer-by-Layer Nanoarchitectonics, Invention, Innovation, and Evolution. Chemistry Letters, 43, 36-68. https://doi.org/10.1246/cl.130987

- 21. Schaaf, P., Voegel, J.C., Jierry, L., et al. (2012) Spray-Assisted Polyelectrolyte Multilayer Buildup, from Step-by-Step to Single-Step Polyelectrolyte Film Constructions. Advanced Materials, 24, 1001-1016. https://doi.org/10.1002/adma.201104227

- 22. Dierendonck, M., De Koker, S., De Rycke, R., et al. (2014) Just Spray It—LbL Assembly Enters a New Age. Soft Matter, 10, 804-807. https://doi.org/10.1039/C3SM52202D

- 23. Li, Y., Wang, X. and Sun, J. (2012) ChemInform Abstract: Lay-er-by-Layer Assembly for Rapid Fabrication of Thick Polymeric Films. Chemical Society Reviews, 41, 5998- 6009. https://doi.org/10.1039/c2cs35107b

- 24. Kirkland, J. (1965) Synthesis of Protocatechuate Oxygenase by Pseudomonas Fluorescens in the Presence of Exogenous Carbon Sources. Analytical Chemistry, 37, 1458-1461. https://doi.org/10.1021/ac60231a004

- 25. Hong, X., Li, J., Wang, M., et al. (2004) Fabrication of Magnetic Luminescent Nanocomposites by a Layer-by-Layer Self-Assembly Approach. Chemistry of Materials, 16, 4022-4027. https://doi.org/10.1021/cm049422o

- 26. Izquierdo, A., Ono, S., Voegel, J.C., et al. (2005) Dipping versus Spraying: Exploring the Deposition Conditions for Speeding Up Layer-by-Layer Assembly. Langmuir, 21, 7558-7567. https://doi.org/10.1021/la047407s

- 27. Chen, D., Zhang, Y., Bessho, T., et al. (2016) Ag Films with Enhanced Adhesion Fabricated by Solution Process for Solar Reflector Applications. Chemical Engineering Journal, 303, 100-108. https://doi.org/10.1016/j.cej.2016.05.114

- 28. Alongi, J., Carosio, F., Frache, A. and Malucelli, G. (2013) Layer by Layer Coatings Assembled through Dipping, Vertical or Horizontal Spray for Cotton Flame Retardancy. Carbohydrate Polymers, 92, 114-119. https://doi.org/10.1016/j.carbpol.2012.08.086

- 29. Mulhearn, W.D., Kim, D.D., Gu, Y. and Lee, D. (2012) Facilitated Transport Enhances Spray Layer-by-Layer Assembly of Oppositely Charged Nanoparticles. Soft Matter, 8, 10419-10427. https://doi.org/10.1039/c2sm26456k

- 30. Merrill, M. and Sun, C. (2009) Fast, Simple and Efficient Assembly of Nanolayered Materials and Devices. Nanotechnology, 20, 075606. https://doi.org/10.1088/0957-4484/20/7/075606

- 31. Krogman, K.C., Zacharia, N.S., Schroeder, S., et al. (2007) Automated Process for Improved Uniformity and Versatility of Layer-by-Layer Deposition. Langmuir, 23, 3137-3141. https://doi.org/10.1021/la063085b

- 32. Gittleson, F.S., Kohn, D.J., Li, X. and Taylor, A.D. (2012) Improving the Assembly Speed, Quality, and Tunability of Thin Conductive Multilayers. ACS Nano, 6, 3703-3711. https://doi.org/10.1021/nn204384f

- 33. Lefort, M., Popa, G., Seyrek, E., et al. (2010) Spray-On Organ-ic/Inorganic Films: A General Method for the Formation of Functional Nano- to Microscale Coatings. Angewandte Chemie International Edition, 49, 10110-10113. https://doi.org/10.1002/anie.201002729

- 34. Gittleson, F.S., Hwang, D., Ryu, W.H., et al. (2015) Ultrathin Nanotube/Nanowire Electrodes by Spin-Spray Layer-by-Layer Assembly, A Concept for Transparent Energy Storage. ACS Nano, 9, 10005-10017. https://doi.org/10.1021/acsnano.5b03578

- 35. Yin, Y., Hu, K., Grant, A.M., et al. (2015) Biopolymeric Nanocomposites with Enhanced Interphases. Langmuir, 31, 10859-10870. https://doi.org/10.1021/acs.langmuir.5b02744

- 36. Salomäki, M., Peltonen, T. and Kankare, J. (2012) Multilayer Films by Spraying on Spinning Surface—Best of Both Worlds. Thin Solid Films, 520, 5550-5556. https://doi.org/10.1016/j.tsf.2012.04.055

- 37. Tang, H., Ji, S., Gong, L., et al. (2013) Tubular Ceramic-Based Multilayer Separation Membranes Using Spray Layer-by-Layer Assembly. Polymer Chemistry, 4, 5621-5628. https://doi.org/10.1039/c3py00617d

- 38. Fukao, N., Kyung, K.H., Fujimoto, K., et al. (2011) Automatic Spray-LBL Machine Based on In-Situ QCM Monitoring. Macromolecules, 44, 2964-2969. https://doi.org/10.1021/ma200024w

- 39. Krogman, K., Cohen, R., Hammond, P., et al. (2013) Industrial-Scale Spray Layer-by-Layer Assembly for Production of Biomimetic Photonic Systems. Bioinspiration Biomimetics, 8, 045005. https://doi.org/10.1088/1748-3182/8/4/045005

- 40. Morton, S.W., Herlihy, K.P., Shopsowitz, K.E., et al. (2013) Scalable Manufacture of Built-to-Order Nanomedicine: Spray-Assisted Layer-by-Layer Functionalization of PRINT® Nanoparticles. Advanced Materials, 25, 4707-4713. https://doi.org/10.1002/adma.201302025

- 41. Qi, A., Chan, P., Ho, J., et al. (2011) Template-Free Synthesis and Encapsulation Technique for Layer-by-Layer Polymer Nanocarrier Fabrication. ACS Nano, 5, 9583-9591. https://doi.org/10.1021/nn202833n

- 42. Wang, Y., Liu, Y., Cheng, Y., et al. (2011) Anatase TiO2 Crystal Facet Growth: Mechanistic Role of Hydrofluoric Acid and Photoelectrocatalytic Activity. Advanced Materials, 23, 5817-5821. https://doi.org/10.1002/adma.201103726

- 43. Thierry, B., Winnik, F.M., Merhi, Y., et al. (2003) Bioactive Coatings of Endovascular Stents Based on Polyelectrolyte Multilayers. Journal of the American Chemical Society, 125, 7494-7495. https://doi.org/10.1021/ja034321x

- 44. Madaboosi, N., Uhlig, K., Jäger, M.S., et al. (2012) Microfluidics as a Tool to Understand the Build-Up Mechanism of Exponential-Like Growing Films. Macromolecular Rapid Communications, 33, 1775-1779. https://doi.org/10.1002/marc.201200353

- 45. Katayama, H., Ishihama, Y. and Asakawa, N. (1998) Stable Cationic Capillary Coating with Successive Multiple Ionic Polymer Layers for Capillary Electrophoresis. Analytical Chemistry, 70, 5272-5277. https://doi.org/10.1021/ac980522l

- 46. Barker, S.L., Ross, D., Tarlov, M.J., et al. (2000) Control of Flow Direction in Microfluidic Devices with Polyelectrolyte Multilayers. Analytical Chemistry, 72, 5925-5929. https://doi.org/10.1021/ac0008690

- 47. Reyes, D.R., Perruccio, E.M., Becerra, S.P., et al. (2004) Micropatterning Neuronal Cells on Polyelectrolyte Multilayers. Langmuir, 20, 8805-8811. https://doi.org/10.1021/la049249a

- 48. Castleberry, S.A., Li, W., Deng, D., et al. (2014) Capillary Flow Lay-er-by-Layer: A Microfluidic Platform for the High-Throughput Assembly and Screening of Nanolayered Film Libraries. ACS Nano, 8, 6580-6589. https://doi.org/10.1021/nn501963q

- 49. Kim, H.J., Lee, K., Kumar, S., et al. (2005) Dynamic Sequential Layer-by-Layer Deposition Method for Fast and Region-Selective Multilayer Thin Film Fabrication. Langmuir, 21, 8532-8538. https://doi.org/10.1021/la0511182

- 50. Hamedi, M., Karabulut, E., Marais, A., et al. (2013) Nanocellulose Aerogels Functionalized by Rapid Layer-by-Layer Assembly for High Charge Storage and Beyond. Angewandte Chemie International Edition, 52, 12038-12042. https://doi.org/10.1002/anie.201305137

- 51. Jin, W., Toutianoush, A. and Tieke, B. (2003) Use of Polyelectrolyte Layer-by-Layer Assemblies as Nanofiltration and Reverse Osmosis Membranes. Langmuir, 19, 2550-2553. https://doi.org/10.1021/la020926f

- 52. Björnmalm, M., Yan, Y. and Caruso, F. (2014) Engineering and Evaluating Drug Delivery Particles in Microfluidic Devices. Journal of Controlled Release, 190, 139-149. https://doi.org/10.1016/j.jconrel.2014.04.030

- 53. Priest, C., Quinn, A., Postma, A., et al. (2008) Microfluidic Polymer Multilayer Adsorption on Liquid Crystal Droplets for Microcapsule Synthesis. Lab Chip, 8, 2182- 2187. https://doi.org/10.1039/b808826h

- 54. Matosevic, S. and Paegel, B.M. (2013) Stepwise Synthesis of Giant Unilamellar Vesicles on a Microfluidic Assembly Line. Nature Chemistry, 5, 958-963. https://doi.org/10.1038/nchem.1765

- 55. Kharlampieva, E., Kozlovskaya, V. and Sukhishvili, S.A. (2009) Layer-by-Layer Hydrogen-Bonded Polymer Films, From Fundamentals to Applications. Advanced Materials, 21, 3053-3065. https://doi.org/10.1002/adma.200803653

- 56. Joseph, N., Ahmadiannamini, P., Hoogenboom, R., et al. (2014) Layer-by-Layer Preparation of Polyelectrolyte Multilayer Membranes for Separation. Polymer Chemistry, 5, 1817-1831. https://doi.org/10.1039/C3PY01262J

- 57. Priest, C., Quinn, A., Postma, A., Zelikin, A.N., Ralston, J. and Caruso, F. (2008) Microfluidic Polymer Multilayer Adsorption on Liquid Crystal Droplets for Microcapsule Synthesis. Lab Chip, 8, 2182-2187.

- 58. Zhang, S., Yobas, L. and Trau, D. (2008) 20th International Conference on Miniaturized Systems for Chemistry and Life Sciences, Chemical and Biological Microsystems Society, 1402-1404.

- 59. Noi, K., Roozmand, A., Bjornmalm, M., et al. (2015) Flow-Based Assembly of Layer-by-Layer Capsules through Tangential Flow Filtration. ACS Applied Materials & Interfaces, 7, 27940-27947. https://doi.org/10.1021/acsami.5b10269

- 60. Björnmalm, M., Roozmand, A., Noi, K.F., et al. (2015) Flow-Based Assembly of Layer-by-Layer Capsules through Tangential Flow Filtration. Langmuir, 31, 9054-9060. https://doi.org/10.1021/acs.langmuir.5b02099

- 61. Correa, S., Choi, K.Y., Dreaden, E.C., et al. (2016) Tu-mor-Targeted Synergistic Blockade of MAPK and PI3K from a Layer-by-Layer Nanoparticle. Advanced Functional Materials, 26, 991-1003. https://doi.org/10.1002/adfm.201504385

- 62. Estrela-Lopis, I., Leporatti, S., Typlt, E., et al. (2007) Small Angle Neutron Scattering Investigations (SANS) of Polyelectrolyte Multilayer Capsules Templated on Human Red Blood Cells. Langmuir, 23, 7209-7215. https://doi.org/10.1021/la700496c

- 63. Brenner, A. (1963) Electrodeposition of Alloys, Principles and Practice. Academic Press, New York.

- 64. Jackson, F., Berlouis, L. and Rocabois, P. (1996) Layer-by-Layer Electrodeposition of Cadmium Telluride onto Silicon. Journal of Crystal Growth, 159, 200-204. https://doi.org/10.1016/0022-0248(95)00819-5

- 65. Zhao, N., Shi, F., Wang, Z. and Zhang, X. (2005) Combining Layer-by-Layer Assembly with Electrodeposition of silver Aggregates for Fabricating Superhydrophobic Surfaces. Langmuir, 21, 4713- 4716. https://doi.org/10.1021/la0469194

- 66. Tanase, M., Silevitch, D., Hultgren, A., et al. (2002) Magnetic Trapping and Self-Assembly of Multicomponent Nanowires. Journal of Applied Physics, 91, 8549-8551. https://doi.org/10.1063/1.1452206

- 67. Dey, S., Mohanta, K. and Pal, A.J. (2010) Magnetic-Field-Assisted Layer-by-Layer Electrostatic Assembly of Ferromagnetic Nanoparticles. Langmuir, 26, 9627-9631. https://doi.org/10.1021/la101132z

- 68. Wang, H., Ishihara, S., Ariga, K., et al. (2012) All-Metal Layer-by-Layer Films: Bimetallic Alternate Layers with Accessible Mesopores for Enhanced Electrocatalysis. American Chemical Society, 134, 10819-10821. https://doi.org/10.1021/ja303773z

- 69. Shi, L., Lu, Y., Sun, J., et al. (2003) Site-Selective Lateral Multilayer Assembly of Bienzyme with Polyelectrolyte on ITO Electrode Based on Electric Field-Induced Directly Layer-by-Layer Deposition. Biomacromolecules, 4, 1161-1167. https://doi.org/10.1021/bm030003e

- 70. Sun, J., Gao, M., Zhu, M., et al. (2002) Layer-by-Layer Depositions of Polyelectrolyte/CdTe Nanocrystal Films Controlled by Electric Fields. Journal of Materials Chemistry, 12, 1775-1778. https://doi.org/10.1039/b111013f

- 71. Van Tassel, P.R. (2012) Carbon Nanotube-Based Antimicrobial Biomaterials Formed via Layer-by-Layer Assembly with Polypeptides. Current Opinion in Colloid & Interface Science, 17, 106-113. https://doi.org/10.1016/j.cocis.2011.08.008

- 72. Sun, J., Gao, M. and Feldmann, J. (2001) Electric Field Directed Layer-by-Layer Assembly of Highly Fluorescent CdTe Nanoparticles. Journal of Nanoscience and Nanotechnology, 1, 133-136. https://doi.org/10.1166/jnn.2001.029

- 73. Richardson, J., Ejima, H., Lörcher, S., et al. (2013) Preparation of Nano- and Microcapsules by Electrophoretic Polymer Assembly. Angewandte Chemie International Edition, 52, 6455-6458. https://doi.org/10.1002/anie.201302092

- 74. Zhang, G., Dai, L., Zhang, L. and Ji, S. (2011) Effects of External Electric Field on Film Growth, Morphology, and Nanostructure of Polyelectrolyte and Nanohybrid Multilayers onto Insulating Substrates. Langmuir, 27, 2093-2098. https://doi.org/10.1021/la104120b

- 75. Omura, Y., Kyung, K.H., Shiratori, S., et al. (2014) Effects of Applied Voltage and Solution pH in Fabricating Multilayers of Weakly Charged Polyelectrolytes and Nanoparticles. Industrial & Engineering Chemistry Research, 53, 11727-11733. https://doi.org/10.1021/ie403736r

- 76. Ngankam, A.P. and Van Tassel, P.R. (2005) In Situ Layer-by-Layer Film Formation Kinetics under an Applied Voltage Measured by Optical Waveguide Light Mode Spectroscopy. Langmuir, 21, 5865-5871. https://doi.org/10.1021/la050066d

- 77. Wang, Z., Zhang, X., Gu, J., et al. (2014) Electrodeposition of Algi-nate/Chitosan Layer-by-Layer Composite Coatings on Titanium Substrates. Carbohydrate Polymers, 103, 38-45. https://doi.org/10.1016/j.carbpol.2013.12.007

- 78. Ariga, K., Hill, J.P. and Ji, Q. (2007) Layer-by-Layer Assembly as a Versatile Bottom-Up Nanofabrication Technique for Exploratory Research and Realistic Application. Physical Chemistry Chemical Physics, 9, 2319-2340. https://doi.org/10.1039/b700410a

- 79. Xie, C., Lu, X., Wang, K., et al. (2016) Biomimetic Mineralized Hierarchical Graphene Oxide/Chitosan Scaffolds with Adsorbability for Immobilization of Nanoparticles for Biomedical Applications. ACS Biomaterials Science & Engineering, 2, 920-928. https://doi.org/10.1021/acsbiomaterials.6b00015

- 80. Rydzek, G., Thomann, J.S., Ben Ameur, N., et al. (2010) Polymer Multilayer Films Obtained by Electrochemically Catalyzed Click Chemistry. Langmuir, 26, 2816-2824. https://doi.org/10.1021/la902874k

- 81. Ye, J.R., Chen, L., Zhang, Y., et al. (2014) Turning the Chitosan Surface from Hydrophilic to Hydrophobic by Layer-by-Layer Electro-Assembly. RSC Advances, 4, 58200-58203. https://doi.org/10.1039/C4RA10327K

- 82. Chen, L., Liu, K., Ye, J.R. and Shen, Q. (2015) Controlled Formation of Surface Hydrophilicity Enhanced Chitosan Film by Layer-by-Layer Electro-Assembly. Materials Science and Engineering: C, 56, 518-521. https://doi.org/10.1016/j.msec.2015.07.021

- 83. Li, M., Zhang, J., Nie, H.J., et al. (2013) In Situ Switching Layer-by-Layer Assembly: One-Pot Rapid Layer Assembly via Alternation of Reductive and Oxidative Electropolymerization. Chemical Communications, 49, 6879-6881. https://doi.org/10.1039/c3cc43629b

- 84. Dey, S. and Pal, A.J. (2010) Magnetic-Field-Assisted Layer-by-Layer Electrostatic Assembly of Ferromagnetic Nanoparticles. Langmuir, 26, 17139-17142. https://doi.org/10.1021/la102996t

- 85. Dey, S. and Pal, A.J. (2011) Layer-by-Layer Electrostatic Assembly with a Control over Orientation of Molecules: Anisotropy of Electrical Conductivity and Dielectric Properties. Langmuir, 27, 8687- 8693. https://doi.org/10.1021/la201471f

- 86. 王智勇, 徐丹. 磁组装薄膜材料的结构及磁各向异性研究[J]. 材料导报, 2015, 29(8): 25-28.

- 87. 叶雅静, 尹大川. 强磁重力环境下的自组装分子膜表征及其对该环境的响应机制[J]. 稀有金属材料与工程, 2010, 39(1): 39-41.

- 88. Bera, A., Dey, S. and Pal, A.J. (2013) Magnetic Moment Assisted Layer-by-Layer Film Formation of a Prussian Blue Analog. Langmuir, 29, 2159-2165. https://doi.org/10.1021/la3036506

- 89. Mu, B., Liu, P., Du, P., Dong, Y. and Lu, C. (2011) Magnetic-Targeted pH-Responsive Drug Delivery System via Layer-by-Layer Self-Assembly of Polyelectrolytes onto Drug-Containing Emulsion Droplets and Its Controlled Release. Journal of Polymer Science Part A, 49, 1969-1976. https://doi.org/10.1002/pola.24623