Hans Journal of Civil Engineering

Vol.06 No.05(2017), Article ID:21994,10

pages

10.12677/HJCE.2017.65060

Experimental Study on Strength Development of Full-Recycled-Aggregate Concrete

Kunqi Yao, Na Liang, Huanhuan Wu, Songwei Pei

Henan Province International United Lab of Eco-Building Materials and Engineering, School of Civil Engineering and Communication, North China University of Water Resources and Electric Power, Zhengzhou Henan

Received: Aug. 24th, 2017; accepted: Sep. 7th, 2017; published: Sep. 11th, 2017

ABSTRACT

This study aims to research and develop a full-recycled-aggregate concrete (aRAC) made of 100% fine and coarse recycled aggregates to get the best benefits by reusing the waste concrete products at the most extent. By changing water-cement ratio and cement strength in mix proportion design of aRAC and the recycled aggregates dealt with pre-wetted process, tests were carried out to study the workability of fresh aRAC and the developments of compressive and tensile strengths of aRAC. Results show that by using proper mix proportion and pre-wetted recycled aggregates, the workability and compressive strength reached the targets, the development of compressive and tensile strengths was almost finished within 56 days, and the increment of tensile strength was lower relating to that of compressive strength at the same curing age.

Keywords:Full-Recycled-Aggregate Concrete (aRAC), Recycled Coarse Aggregate, Recycled Fine Aggregate, Strength Development

全再生骨料混凝土强度发展规律试验研究

姚坤奇,梁娜,毋欢欢,裴松伟

华北水利水电大学土木与交通学院,河南省生态建材工程国际联合实验室,河南 郑州

收稿日期:2017年8月24日;录用日期:2017年9月7日;发布日期:2017年9月11日

摘 要

本研究采用100%再生细骨料和再生粗骨料配制全再生骨料混凝土,以最大程度利用废旧混凝土再生骨料并取得最佳经济效益。考虑再生骨料预湿处理并变换水灰比和水泥强度进行配合比设计,进行了全再生骨料混凝土工作性能和抗压强度、抗拉强度发展规律的试验研究。结果表明:通过合理的配合比设计和再生骨料预湿处理,全再生骨料混凝土的工作性能和抗压强度均达到设计要求;抗压和抗拉强度的发展几乎在养护龄期56 d之内完成,且抗拉强度的增长低于抗压强度。

关键词 :全再生骨料混凝土,再生粗骨料,再生细骨料,强度发展规律

Copyright © 2017 by authors and Hans Publishers Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

1. 引言

在我国城镇化快速发展过程中,随着可持续发展和环境友好型城镇建设理念的广泛运用,建筑垃圾再生利用成为必然趋势。由废弃混凝土破碎加工成再生骨料后,重新用于生产再生骨料混凝土,也得到越来越多的研究和工程应用 [1] [2] 。同时,对再生骨料及再生骨料混凝土的认识也更加深入。

再生粗骨料具有不同于天然碎石骨料的一些特性,直接影响再生骨料混凝土性能。黏附母体水泥砂浆的粗糙表面导致再生粗骨料与新混凝土基体黏结强度的不确定性:或产生薄弱黏结界面 [3] [4] [5] [6] [7] ,或在一定粒径范围因棱角性产生增强黏结界面 [8] [9] 。较低的密实性与较高、快速的吸水性增大了再生骨料混凝土配合比设计和拌合物制备的难度,增加了再生骨料混凝土性能评价与设计指标确定的复杂性:影响效果是否有利取决于母体混凝土性能、破碎工艺和骨料粒径 [3] [5] [7] [9] [10] [11] [12] [13] 。为了消除其不利影响,研发了各种再生粗骨料处理工艺。加热摩擦方法和超声波清除技术,被用于除去再生粗骨料表面黏附的母体水泥砂浆 [14] [15] ;碳酸盐微生物沉淀、碱性有机硅化合物和盐酸复合偏硅酸钙等表面处治方法,有助于提高再生粗骨料自重并降低其吸水率 [16] [17] [18] ;借助于高强度水泥浆或预涂层材料,填充再生粗骨料表面的孔隙和微裂缝 [19] - [24] ;将再生粗骨料在水中浸泡30 d使未水化水泥颗粒重新发生水化反应而产生自愈合效应,以提高再生粗骨料颗粒性能 [21] 。综合比较,经济可行的做法是在搅拌前预湿再生粗骨料,能够使再生骨料混凝土拌合物工作性能和硬化混凝土性能得到普遍改善。

在现有研究文献中,通常将再生粗骨料替代率(再生粗骨料与全部骨料的比值)作为一个重要参数,反映再生粗骨料含量对混凝土性能的影响。一般地,当配合比相同或相似时,随着替代率的增加,再生骨料混凝土的抗压强度、抗拉强度和弹性模量减小 [5] [7] [12] [13] [19] [24] [25] 。但这一结论的工程应用却存在明显问题:从混凝土技术角度,为了获得相同的抗压强度和工作性能,当再生骨料替代率不同时,再生骨料混凝土配合比是需要调整的;从混凝土结构设计角度,混凝土设计指标对应于其强度等级,不必规定采用何种骨料 [26] 。研究业已表明,通过采用合理的配合比设计 [10] [27] 、适当的矿物掺和料 [10] [20] [21] [28] 、预湿再生粗骨料和恰当的拌合工艺 [20] [21] [22] [23] [29] ,或者对再生粗骨料表面进行改性处理 [17] [18] ,再生骨料混凝土的性能完全可以达到甚至超过相同强度等级的天然碎石混凝土。

与天然砂比较,再生细骨料也具有明显不同的特性,诸如多棱角不规则颗粒、含有凝胶和氢氧化钙化合物的不均质形貌的砂浆、低密度和高吸水率 [5] [7] [30] [31] 。一些研究表明掺加再生细骨料配制的混凝土,表现出较差的工作性能和力学性能 [5] [7] [32] [33] 。但也有研究表明采用部分再生细骨料,或者采用再生细骨料并添加高效减水剂,可使制备的再生骨料混凝土性能至少不低于天然砂混凝土 [32] [33] [34] 。

由于再生粗骨料和再生细骨料是废旧混凝土的共同产物,单独利用其一均不能获取最佳效益。综合分析上述文献资料,已有一些成功案例,采用全部再生粗骨料或全部再生细骨料,或者同时采用部分再生粗骨料和再生细骨料,可配制出与天然骨料混凝土同样性能的再生骨料混凝土 [35] [36] 。因此,研发采用100%再生粗、细骨料配制全再生骨料混凝土,在技术上是可行的。这样可以在最大程度上利用再生骨料,并尽可能减少混凝土生产设备和拌制工艺的变动,更有利于再生骨料混凝土在预拌混凝土产业中推广应用。

因此,本课题确定了制备全再生骨料混凝土的总体目标。前期研究表明 [37] ,在配合比设计时通过调整水灰比、砂率等参数,可使全再生骨料混凝土获得优良的拌合物工作性能,并达到设定的混凝土配制强度;全再生骨料混凝土轴心抗压强度可按现行混凝土结构设计规范规定取值,但其抗拉强度和弹性模量按规范取值则偏大。作为一种新的混凝土制备方案,同其他新型混凝土一样,为了保障其在结构工程中应用的可靠度,必须研究清楚其强度发展规律 [38] [39] [40] 。因此,作为课题研究计划的组成部分,本文介绍了全再生骨料混凝土强度发展规律的研究成果。

2. 试验概况

2.1. 原材料

采用42.5和52.5级普通硅酸盐水泥,其物理力学性能实测结果见表1。

再生粗骨料按照规范GB/T 25177的规定 [1] ,由实验室5年前试验的钢筋混凝土梁破碎,经筛分为粒径5~20 mm连续级配。其物理力学性能实测结果见表2。

再生细骨料是破碎再生粗骨料过程中粒径小于5 mm的共生产物,按照规范GB/T 25176的规定 [2] ,经筛分级配而成,其物理力学性能实测结果见表3。

其他原材料包括拌合用自来水和减水率为25%的高效减水剂。

2.2. 混凝土配合比

如表4所列,全再生骨料混凝土的配合比在前期研究基础上,根据规范JGJ 55的规定的绝对体积法

Table 1. Physical and mechanical properties of cement

表1. 水泥的物理力学性能

Table 2. Physical and mechanical properties of recycled coarse aggregate

表2. 再生粗骨料的物理力学性能

Table 3. Physical and mechanical properties of recycled fine aggregate

表3. 再生细骨料的物理力学性能

Table 4. Mix proportion of recycled aggregate concrete

表4. 全再生骨料混凝土的配合比

Table 5. Test plan and curing age

表5. 试验方案与养护龄期

计算确定 [37] [41] 。42.5级水泥用于配制C30和C40全再生骨料混凝土,52.5级水泥用于配制C50全再生骨料混凝土。减水剂用量为水泥用量的0.75%~1.0%,根据拌合物工作性能加以调整。附加用水量由再生骨料吸水率确定,用于再生骨料的预湿处理。拌合程序:向搅拌机内投入再生粗骨料和再生细骨料,搅拌均匀并加入附加用水预湿1 h;加入水泥并搅拌均匀;加入拌合水和减水剂,搅拌5 min。

2.3. 试验方法

全再生骨料混凝土的坍落度试验按照规范GB/T 50080的规定进行 [42] 。抗压强度和抗拉强度试验按照规范GB/T 50081的规定进行 [43] 。边长150 mm立方体试块用于立方体抗压强度和劈裂抗拉强度试验,150 mm ´ 150 mm ´ 300 mm棱柱体试件用于轴心抗压强度试验。试件均在振动台振实,抹面后覆盖塑料薄膜。成型24 h脱模并移入温度20℃ ± 2℃的标准养护池中水养。每个强度等级的混凝土试件在同一天浇筑成型,3个一组进行同一指标试验。试验方案和养护龄期见表5。

3. 试验结果分析

3.1拌合物工作性能

全再生骨料混凝土拌合物均具有良好的粘聚性、保水性和流动性,坍落度试验值为145~165 mm。

3.2 抗压强度发展规律

立方体试块受压破坏,均呈现四个立面对称开裂、脱落的对顶锥体。棱柱体试件受压破坏,均呈现中部因横向膨胀而产生竖向裂缝,如图1所示。破坏面上没有发现压碎的再生粗骨料,呈现出再生粗骨料与水泥浆体界面的黏结破坏。因此,全再生骨料混凝土的受压破坏与普通混凝土一致。

相对于养护龄期56 d的全再生骨料混凝土抗压强度发展规律如图2所示。由图可见,抗压强度在养护龄期28 d前增长很快,随后增长减缓并在一定幅度内变动。与42.5级水泥配制的全再生骨料混凝土比较,52.5级水泥配制的全再生骨料混凝土强度增长较快。这与表1所列的52.5级水泥细度大、3 d抗压强度高直接相关,水泥颗粒细度大为水泥快速水化反应提供了更大的界面面积,水泥较高的早期强度则直接提高了全再生骨料混凝土的水泥浆体早期强度。与机制砂混凝土研究结果类似 [38] ,这些强度发展也与水灰比相关。由于本试验的拌合用水量是定值,较大的水灰比意味着可提供较多的自由水进行内养护而为水泥颗粒的持续水化反应提供了潮湿环境。然而,全再生骨料混凝土在养护龄期超过56 d之后的强度增长微弱,是与机制砂混凝土强度增长规律明显不同的。

(a)

(a)

(b)

(b)

Figure 1. Failure modes of cube and prism under compression; (a) Cube; (b) Prismoid

图1. 立方体和棱柱体受压破坏形态;(a) 立方体;(b) 棱柱体

Figure 2. The change of compressive strength with the curing age

图2. 抗压强度随养护龄期的变化

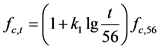

全再生骨料混凝土在养护龄期t时的立方体抗压强度fcu,t可采用式(1)预测

(1)

(1)

式中:fcu,t为全再生骨料混凝土在养护龄期t时的立方体抗压强度,MPa;fcu,56为全再生骨料混凝土在养护龄期56 d时的立方体抗压强度,MPa;t为养护龄期,d;3 ≤ t ≤ 56。当t > 56,fcu,t = fcu,56。采用42.5级水泥时,k1 = 0.45;采用52.5级水泥时,k1 = 0.33。

全再生骨料混凝土在养护龄期t时的轴心抗压强度fc,t可采用式(2)预测

(2)

(2)

式中:fc,t为全再生骨料混凝土在养护龄期t时的轴心抗压强度,MPa;fc,56为全再生骨料混凝土在养护龄期56 d时的轴心抗压强度,MPa。其他符号规定同式(1)。

图3示出了全再生骨料混凝土在养护龄期56 d内的抗压强度实测值与式(1)和式(2)计算值的比较结果。除了养护龄期3 d偏差较大外,整体上符合程度良好。

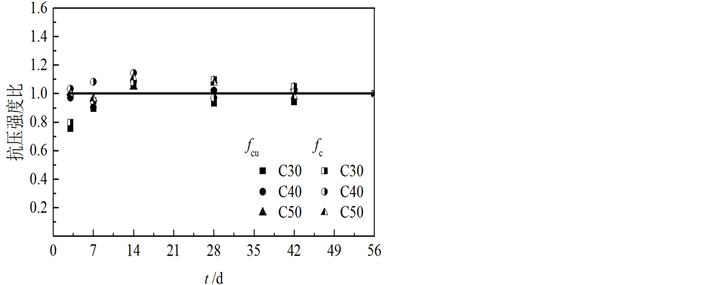

鉴于立方体抗压强度仅用于确定混凝土的强度等级,而由强度等级推算的轴心抗压强度是混凝土结构设计必须的技术指标。因此,图4绘出了不同养护龄期时全再生骨料混凝土的轴心/立方体抗压强度比 (fc,t/fcu,t),对应于C30、C40和C50全再生骨料混凝土的平均值为0.75~0.98、0.80~1.01和0.84~1.11。表

Figure 3. The change of compressive strength ratio with curing age

图3. 抗压强度比随养护龄期的变化

Figure 4. The change of axial/cubic compressive strength ratio with curing age

图4. 轴心/立方体抗压强度比随养护龄期的变化

明此比值随着抗压强度的提高而增大,这源于再生骨料间的自锁效应降低了棱柱体横向膨胀变形,有利于提高轴心抗压强度 [6] [10] 。

图4也示出了试验结果与规范GB 50010换算公式(3)计算结果的比较。试验值普遍高于计算值,意味着将全再生骨料混凝土用于混凝土结构构件的受压是安全的。

(3)

(3)

3.3. 抗拉强度发展规律

图5为全再生骨料混凝土劈裂抗拉试验的典型破坏面,破坏面因骨料与水泥浆体界面破坏而凹凸不平,伴随有少量再生粗骨料断裂。

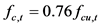

图6绘出了全再生骨料混凝土相对于养护龄期56 d时的劈裂抗拉强度发展规律。可以看出,劈裂抗拉强度与抗压强度的发展规律相似。与养护龄期28 d时比较,C30、C40和C50全再生骨料混凝土劈裂抗拉强度在养护龄期3 d时依次达到了49.1%,74.1%和88.8%,在养护龄期7 d时依次达到了71.6%、93.6%和94.2%。这意味着抗压强度高的全再生骨料混凝土,其劈裂抗拉强度的发展也较快。

由于混凝土结构设计使用的抗拉强度指标是由立方体抗压强度(强度等级)推算的,对本试验数据的统计结果可采用式(4),相关系数为0.824。

(4)

(4)

Figure 5. Splitting tensile typical failure surface

图5. 劈裂抗拉典型破坏面

Figure 6. Change of tensile strength with curing age

图6. 抗拉强度随养护龄期的变化

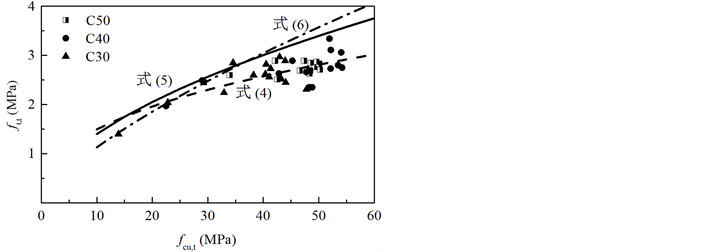

Figure 7. Comparison of test and calculated values of tensile strength

图7. 抗拉强度试验值与计算值的比较

式(4)中,ft,t为全再生骨料混凝土在养护龄期t时的劈裂抗拉强度,MPa。

图7绘出了试验结果与规范GB 50010换算公式(5) [26] 、机制砂混凝土换算公式(6) [39] 的比较。由图7可见,全再生骨料混凝土的抗拉强度试验值低于式(5)、式(6)的计算值。这表明全再生骨料混凝土的抗拉强度偏低,在混凝土结构构件设计时需要进行修正。

(5)

(5)

(6)

(6)

4. 结论

1) 同前期研究一致,采用合适的配合比和再生骨料预湿处理方法,全再生骨料混凝土的工作性能和抗压强度能够达到配制目标。在本研究仅采用水泥作为胶凝材料的情况下,全再生骨料混凝土的抗压和抗拉强度发展几乎在养护龄期56 d内完成,后期强度发展甚微,且抗拉强度增长低于同龄期抗压强度的增长。

2) 全再生骨料混凝土轴心抗压强度与立方体抗压强度的比值高于规范GB 50010的规定值,采用规范规定值用于结构构件抗压承载设计是安全的。

3) 与相同强度等级的普通混凝土比较,全再生骨料混凝土的抗拉强度偏低。结构构件设计采用抗拉强度指标时,需要进行修正。

4) 鉴于全再生骨料混凝土强度发展的影响因素复杂,本文研究结论的普适性尚需进一步的系统试验研究加以印证。

基金项目

河南省高等学校重点科研项目(16A560023),河南省新型城镇建筑技术协同创新中心(教科技[2013]638号)科研课题资助。

文章引用

姚坤奇,梁 娜,毋欢欢,裴松伟. 全再生骨料混凝土强度发展规律试验研究

Experimental Study on Strength Development of Full-Recycled-Aggregate Concrete[J]. 土木工程, 2017, 06(05): 498-507. http://dx.doi.org/10.12677/HJCE.2017.65060

参考文献 (References)

- 1. GB/T 25177-2010. 混凝土用再生粗骨料[S].

- 2. GB/T 25176-2010. 混凝土和砂浆用再生细骨料[S].

- 3. Nagataki, S., Gokce, A., Saeki, T., et al. (2004) Assessment of Recycling Process Induced Damage Sensitivity of Recycled Concrete Aggregate. Cement and Concrete Research, 34, 965-971. https://doi.org/10.1016/j.cemconres.2003.11.008

- 4. Vivian Tam, W.Y., Gao, X.P. and Tam, C.M. (2005) Microstructural Analysis of Recycled Aggregate Concrete Produced from Two-Stage Mixing Approach. Cement and Concrete Research, 35, 1195-1203. https://doi.org/10.1016/j.cemconres.2004.10.025

- 5. Li, X. (2008) Recycling and Reuse of Waste Concrete in China Part I. Material Behaviour of Recycled Aggregate Concrete. Resources, Conservation and Recycling, 53, 36-44. https://doi.org/10.1016/j.resconrec.2008.09.006

- 6. 肖建庄, 刘琼, 李文贵, 等. 再生混凝土细微观结构和破坏机理研究[J]. 青岛理工大学学报, 2009, 30(4): 24-30.

- 7. Xiao, J., Li, W., Fan, Y., et al. (2012) An Overview of Study on Recycled Aggregate Concrete in China (1996-2011). Construction and Building Materials, 31, 364-383. https://doi.org/10.1016/j.conbuildmat.2011.12.074

- 8. Lee, G.C. and Choi, H.B. (2013) Study on Interfacial Transition Zone Properties of Recycled Aggregate by Micro-Hardness Test. Construction and Building Materials, 40, 455-460. https://doi.org/10.1016/j.conbuildmat.2012.09.114

- 9. Seo, D.S. and Choi, H.B. (2014) Effects of the Old Cement Mortar Attached to the Recycled Aggregate Surface on the Bond Characteristics between Aggregate and Cement Mortar. Construction and Building Materials, 59, 72-79. https://doi.org/10.1016/j.conbuildmat.2014.02.047

- 10. Butler, L., West, J.S. and Tighe, S.L. (2013) Effect of Recycled Concrete Coarse Aggregate from Multiple Sources on the Hardened Properties of Concrete with Equivalent Compressive Strength. Construction and Building Materials, 47, 1292-1301. https://doi.org/10.1016/j.conbuildmat.2013.05.074

- 11. Kou, S. and Poon, C. (2015) Effect of the Quality of Parent Concrete on the Properties of High Performance Recycled Aggregate Concrete. Construction and Building Materials, 77, 501-508. https://doi.org/10.1016/j.conbuildmat.2014.12.035

- 12. Lotfi, S., Eggimann, M., Wagner, E., et al. (2015) Performance of Recycled Aggregate Concrete Based on a New Concrete Recycling Technology. Construction and Building Materials, No. 95, 243-256.

- 13. Kim, H. and Goulias, D.G. (2015) Shrinkage Behavior of Sustainable Concrete with Crushed Returned Concrete Aggregate. Journal of Materials in Civil Engineering, 27, 04014204.

- 14. Katz, A. (2004) Treatment for the Improvement of Recycled Aggregate. Journal of Materials in Civil Engineering, 16, 597-603. https://doi.org/10.1061/(ASCE)0899-1561(2004)16:6(597)

- 15. Shima, H., Tateyashiki, H., Matsuhashi, R., et al. (2005) An Advanced Concrete Recycling Technology and Its Application Assessment through Input-Output Analysis. Journal of Advanced Concrete Technology, 3, 53-67. https://doi.org/10.3151/jact.3.53

- 16. Qiu, J., Tng, D.Q.S. and Yang, E.H. (2014) Surface Treatment of Recycled Concrete Aggregates through Microbial Carbonate Precipitation. Construction and Building Materials, No. 57, 144-150.

- 17. Ismail, S. and Ramli, M. (2014) Mechanical Strength and Drying Shrinkage Properties of Concrete Containing Treated Coarse Recycled Concrete Aggregates. Construction and Building Materials, No. 68, 726-739.

- 18. Cui, H.Z., Shi, X., Memon, S.A., et al. (2015) Experimental Study on the Influence of Water Absorption of Recycled Coarse Aggregates on Properties of the Resulting Concretes. Journal of Materials in Civil Engineering, 27, 04014138.

- 19. Otsuki, N., Miyazato, S. and Yodsudjai, W. (2003) Influence of Recycled Aggregate on Interfacial Transition Zone, Strength, Chloride Penetration and Carbonation of Concrete. Journal of Materials in Civil Engineering, 15, 443-451. https://doi.org/10.1061/(ASCE)0899-1561(2003)15:5(443)

- 20. Corinaldesi, V. and Moriconi, G. (2009) Influence of Mineral Additions on the Performance of 100% Recycled Aggregate Concrete. Construction and Building Materials, No. 23, 2869-2876.

- 21. Elhakam, A.A., Mohamed, A.E. and Awad, E. (2012) Influence of Self-Healing, Mixing Method and Adding Silica Fume on Mechanical Properties of Recycled Aggregates Concrete. Construction and Building Materials, No. 35, 421-427.

- 22. Brand, A.S., Roesler, J.R. and Salas, A. (2012) Initial Moisture and Mixing Effects on Higher Quality Recycled Coarse Aggregate Concrete. Construction and Building Materials, No. 26, 565-573.

- 23. Liang, Y., Ye, Z., Vernerey, F., et al. (2015) Development of Processing Methods to Improve Strength of Concrete with 100% Recycled Coarse Aggregate. Journal of Materials in Civil Engineering, 27, 04014163.

- 24. Li, J., Xiao, H. and Zhou, Y. (2009) Influence of Coating Recycled Aggregate Surface with Pozzolanic Powder on Properties of Recycled Aggregate Concrete. Construction and Building Materials, 23, 1287-1291.

- 25. Ho, N.Y., Lee, Y.P.K., Lim, W.F., et al. (2013) Efficient Utilization of Recycled Concrete Aggregate in Structural Concrete. Journal of Materials in Civil Engineering, 25, 318-327. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000587

- 26. GB 50010-2010. 混凝土结构设计规范[S].

- 27. Fathifazl, G., Razaqpur, A.G., Isgor, O.B., et al. (2011) Creep and Drying Shrinkage Characteristics of Concrete Produced with Coarse Recycled Concrete Aggregate. Cement & Concrete Composites, No. 33, 1026-1037.

- 28. Kou, S., Poon, C. and Agrela, F. (2011) Comparisons of Natural and Recycled Aggregate Concretes Prepared with the Addition of Different Mineral Admixtures. Cement & Concrete Composites, No. 33, 788-795.

- 29. Yildirim, S.T., Meyer, C. and Herfellner, S. (2015) Effects of Internal Curing on the Strength, Drying Shrinkage and Freeze-Thaw Resistance of Concrete Containing Recycled Concrete Aggregates. Construction and Building Materials, No. 91, 288-296.

- 30. Guedes, M., Evangelista, L., Brito De, J., et al. (2013) Microstructural Characterization of Concrete Prepared with Recycled Aggregates. Microscopy and Microanalysis, No. 19, 1222-1230. https://doi.org/10.1017/S1431927613001463

- 31. Evangelista, L., Guedes, M., Brito De, J., et al. (2015) Physical, Chemical and Mineralogical Properties of Fine Recycled Aggregates Made from Concrete Waste. Construction and Building Materials, No. 86, 178-188.

- 32. Evangelista, L. and Brito De, J. (2007) Mechanical Behaviour of Concrete Made with Fine Recycled Concrete Aggregates. Cement & Concrete Composites, 29, 397-401.

- 33. Evangelista, L. and Brito De, J. (2010) Durability Performance of Concrete Made with Fine Recycled Concrete Aggregates. Cement & Concrete Composites, No. 32, 9-14.

- 34. Pereira, P., Evangelista, L. and Brito De, J. (2012) The Effect of Superplasticisers on the Workability and Compressive Strength of Concrete Made with Fine Recycled Concrete Aggregates. Construction and Building Materials, No. 28, 722-729.

- 35. Manzi, S., Mazzotti, C. and Bignozzi, M.C. (2013) Short and Long-Term Behavior of Structural Concrete with Recycled Concrete Aggregate. Cement & Concrete Composites, No. 37, 312-318.

- 36. Lotfy, A. and Al-Fayez, M. (2015) Performance Evaluation of Structural Concrete using Controlled Quality Coarse and Fine Recycled Concrete Aggregate. Cement & Concrete Composites, No. 61, 36-43.

- 37. 李晓克, 郭琦, 赵顺波, 等. 全再生骨料混凝土配合比设计与试验研究[J]. 华北水利水电学院学报(自然科学版), 2013, 34(4): 53-56.

- 38. Ding, X., Li, C., Xu, Y., et al. (2016) Experimental Study on Long-Term Compressive Strength of Concrete with Manufactured Sand. Construction and Building Materials, No. 108, 67-73.

- 39. Zhao, S., Ding, X., Zhao, M., et al. (2017) Experimental Study on Tensile Strength Development of Concrete with Manufactured Sand. Construction and Building Materials, No. 138, 247-253.

- 40. 李晓克, 张晓燕, 李长永, 等. 钢纤维全轻混凝土长期强度和碳化性能试验研究[J]. 土木工程与管理学报, 2017, 34(2): 46-50.

- 41. JGJ 55-2011. 普通混凝土配合比设计规程[S].

- 42. GB/T 50080-2002. 普通混凝土拌合物性能实验方法标准[S].

- 43. GB/T 50081-2002. 普通混凝土力学性能试验方法标准[S].