Material Sciences

Vol.07 No.01(2017), Article ID:19479,9

pages

10.12677/MS.2017.71006

Microstructure and Electrical Properties of (1−x)(K0.5Na0.5)NbO3-xBa0.985La0.01TiO3 Lead-Free Ceramics

Hualei Cheng1,2*, Jian Xiao1, Peng Gao1, Yunyun Yan1, Shuanping Gao1

1Shaanxi Key Laboratory of Phytochemistry, Department of Chemistry, Baoji University of Arts and Science, Baoji Shaanxi

2State Key Laboratory of Solidification Processing, Northwestern Polytechnical University, Xi’an Shaanxi

Received: Dec. 20th, 2016; accepted: Jan. 6th, 2017; published: Jan. 9th, 2017

Copyright © 2017 by authors and Hans Publishers Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

ABSTRACT

The (1−x)(K0.5Na0.5)NbO3-xBa0.985La0.01TiO3 (KNN-xBLT, x = 0.01, 0.02, 0.04, 0.05) lead-free ceramics were prepared by the conventional solid-state sintering method. It was found that the phase structure of KNN-xBLT ceramics changed from the orthorhombic phase to the tetragonal phase with the increase of BLT content. When x = 0.04, the phase structure of KNN-xBLT ceramics was orthorhombic and tetragonal phase coexisting. The density increased and the grain size decreased with BLT increased. The dielectric constant of the KNN-xBLT ceramics increased with the increase of BLT content and the Curie temperature shifted to the low temperature in the temperature range from room temperature to 350˚C. The 0.95KNN-0.05BLT ceramic was a relaxor ferroelectric with high dielectric constant of ɛ > 4000 and the low dielectric loss of tanδ < 0.02 in the temperature range from room temperature to 350˚C. These results indicate that 0.95KNN-0.05BLT ceramics are promising candidate materials for preparing the high temperature multilayer ceramics capacitors. The 0.96KNN-0.04BLT ceramics obtain the optimum piezoelectric properties: d33 = 185 pC/N, kp = 0.39.

Keywords:Lead-Free Ceramic, Potassium Sodium Niobate, Electrical Properties

(1−x)(K0.5Na0.5)NbO3-xBa0.985La0.01TiO3无铅陶瓷的微观结构及电性能研究

程花蕾1,2*,肖健1,高鹏1,严云云1,高拴平1

1宝鸡文理学院化学与化工学院陕西省植物重点实验室,陕西 宝鸡

2西北工业大学凝固技术国家重点实验室,陕西 西安

收稿日期:2016年12月20日;录用日期:2017年1月6日;发布日期:2017年1月9日

摘 要

采用传统固相烧结法制备(1−x)(K0.5Na0.5)NbO3-xBa0.985La0.01TiO3 (KNN-xBLT, x = 0.01、0.02、0.04、0.05)无铅陶瓷并研究了BLT掺杂对KNN陶瓷性能的影响。结果表明:BLT的掺杂抑制了KNN-xBLT陶瓷晶粒的生长使陶瓷晶粒尺寸更均匀。在室温至350℃范围内,KNN-xBLT陶瓷的介电常数随着BLT掺杂量的增加而增大且居里温度向低温方向移动。0.95KNN-0.05BLT陶瓷是一种弛豫铁电体且在室温至350℃范围内最大介电常数4000,介电损耗小于0.02,暗示其在高温陶瓷电容器介质材料方面的应用潜力。在研究的组成范围内,KNN-xBLT陶瓷的相结构随BLT掺杂量的增加由正交相转变为四方相,当x = 0.04时,KNN-xBLT陶瓷为正交和四方两相共存。0.96KNN-0.04BLT陶瓷因正交相和四方相共存压电性能有所提高(d33 = 185 pC/N, kp = 0.39),但距铅基压电陶瓷的性能还有差距。

关键词 :无铅陶瓷,铌酸钾钠,电性能

1. 引言

钛酸铋钠(Bi0.5Na0.5)TiO3(简写为BNT)是过去10年间研究最广泛的钙钛矿结构无铅压电陶瓷之一。然而,由于BNT在室温下的矫顽场Ec(73 kV/cm)很高,并且很难充分极化,所以难以获得可实用的压电陶瓷。国内外学者从A位、B位和A、B位复合取代的角度作了大量改性研究,提出了若干BNT基新体系 [1] - [8] 。但改性提高BNT材料性能的同时往往伴随着退极化温度的降低,从而使得BNT材料无法获得实际使用。

铌酸钾钠(K0.5Na0.5)NbO3(简写为KNN)基无铅压电陶瓷近年来也受到了广泛的关注。因为KNN陶瓷不仅具有比其它无铅压电陶瓷相对较高的压电性能(d33 = 80 - 110pC/N)和较高的居里温度(420℃),而且KNN基无铅压电陶瓷与人体组织具有良好的兼容性,可以直接植入人的体内,是对人类和环境非常友好的材料,故被认为是非常有前途替代PZT的无铅压电材料 [9] - [14] 。然而,KNN固溶体的相稳定温度被限制在1140℃,故KNN陶瓷的烧结温度必须低于1140℃,所以,难于烧结是限制KNN陶瓷性能的重要因素之一。同时,与PZT陶瓷相比,KNN陶瓷的压电性能还很低,还远不能达到应用要求。为了克服上述缺陷,国内外学者作了大量研究。主要从以下几方面入手:1) 添加烧结助剂 [15] [16] [17] [18] ;2) 采用不同的烧结方法,如热压烧结和放电等离子体烧结等 [19] [20] [21] ;3) 加入不同添加剂与KNN形成二元体系 [22] [23] [24] [25] 。在这些改进方法中,通过掺杂改性能够在一定程度上改进铌酸钾钠基无铅陶的物理性能得到具有高性能的功能性材料。BaTiO3的压电性能较高但居里温度仅为120℃;KNN居里温度高但剩余极化和机械耦合系数比较高。文献报道在KNN陶瓷中添加BaTiO3组分有助于陶瓷的烧结,降低相转变温度,抑制水解,且KNN-BT陶瓷同时兼具高的居里温度和压电性能 [26] 。La3+在BaTiO3体系中取代能够提高体系的介电常数,同时使居里峰展宽,出现弥散相变特性 [27] 。鉴于文献报道基础,本文采用Ba0.985La0.01TiO3为第二组份对KNN陶瓷进行掺杂改性,制备了(1−x)(K0.5Na0.5)NbO3-xBa0.985La0.01TiO3 (KNN-xBLT, x = 0.01, 0.02, 0.04, 0.05)陶瓷,并对其结构和介电性能进行了分析和讨论。

2. 实验

本实验采用传统的固相烧结法进行样品的制备。实验原料主要为分析纯的Na2CO3 (99.8%)、K2CO3 (99.0%)、BaCO3 (99.0%)、Nb2O5 (99.9%)、La2O3 (99.0%)、TiO2 (99.0%)。按设计配比称量试剂,以无水乙醇为介质在行星式球磨机中球磨24 h。将烘干后的粉料在950℃下保温5 h进行预烧,预烧后的粉末样品中加入PVA粘结助剂,研磨造粒,并使用电动压片机在8 MPa压力下将粉料压成直径约为12 mm,厚度约为2 mm的小圆片。圆片试样经过600℃保温2 h的排胶过程后,再进行烧结。烧结时,选取烧结温度分别为1135℃、1130℃、1125℃和1110℃,保温时间为2 h,升温速率为5℃/min。在测试陶瓷试样介电性能前要在试样经打磨抛光后的表面被银,被银温度为810℃,保温30 min。

采用X射线衍射仪(荷兰X’Pert MPD Pro型自动X射线衍射仪)分析烧结后试样的物相组成;采用扫描电镜(捷克TESCAN生产的VEGA3 LMU型扫描电子显微镜)观察试样的微观形貌;使用精密LCR分析仪TH2816测量已被银试样在1 kHz,10 kHz,100 kHz,1000 kHz频率下的介电温谱和介电损耗,测量温度范围为25℃~550℃。使用TF2000测试样品的电滞回线。用ZJ-3A准静态测量仪(中国科学院声学研究所)测量d33。用HP4294A型精密阻抗测试仪测试样品的谐振—反谐振频率并计算kp。

3. 结果与讨论

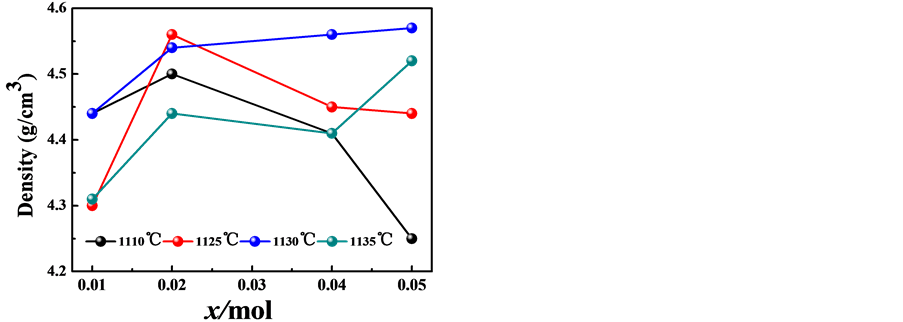

图1为不同烧结温度下KNN-xBLT (0.01 ≤ x ≤ 0.05)陶瓷的密度曲线图。由图可以看出KNN-xBLT陶瓷在烧结温度为分别为1110℃、1125℃、1130℃和1135℃时,1130℃烧结的KNN-xBLT陶瓷的密度较大,说明1130℃为该陶瓷的最优烧结温度,后面的表征测试均在最优烧结温度下进行。在最优烧结温度1130℃时,KNN-xBLT陶瓷的密度随着BLT掺杂量的增加逐渐增大,x = 0.05时,KNN-xBLT陶瓷具有最大密度,ρmax = 4.57 g/cm3。

图2为KNN-xBLT陶瓷样品的SEM照片。从图2中可以看出KNN-xBLT陶瓷样品晶粒尺寸随BLT掺杂量增加明显减小且更加均匀。x = 0.01时,KNN-xBLT陶瓷的晶粒大小不均匀,大晶粒尺寸约为7 μm,小晶粒尺寸约3 μm;x = 0.02时,KNN-xBLT陶瓷晶粒尺寸约为3 μm,有少量约为1.5 μm的晶粒掺杂在其中;x = 0.04时,KNN-xBLT陶瓷晶粒尺寸约为1 μm,晶粒尺寸比较均匀;x = 0.05时,KNN-xBLT陶瓷晶粒尺寸比较均匀约0.75 μm,陶瓷更加致密。说明BLT的掺杂抑制KNN-xBLT陶瓷晶粒的生长,使陶瓷晶粒尺寸更均匀。

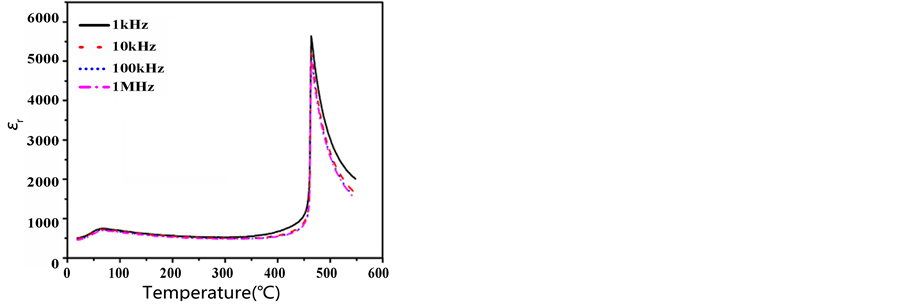

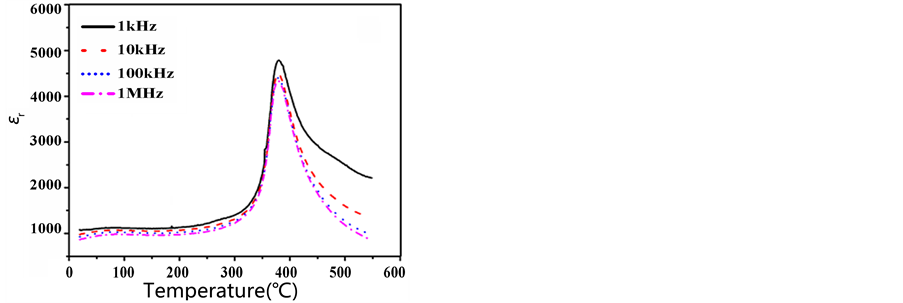

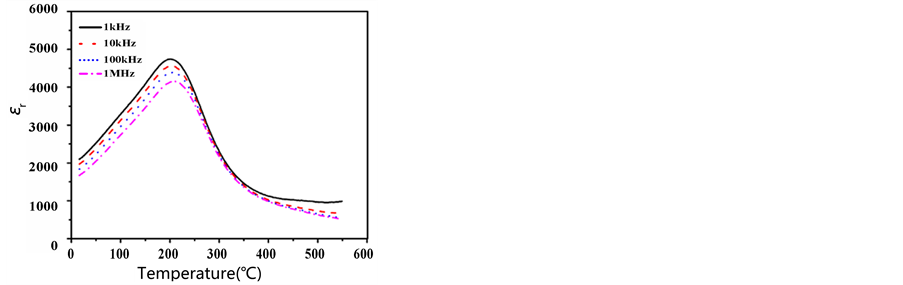

图3是KNN-xBLT陶瓷不同频率下介电常数随温度的变化曲线。BLT掺杂使KNN-xBLT陶瓷的介电性能发生有趣的变化。首先,x = 0.01时,KNN-xBLT陶瓷具有两个介电峰分别对应于正交-四方相变和四方-立方相变;x = 0.02,0.04,0.05时,KNN-xBLT陶瓷只有一个介电峰;第二,KNN-xBLT陶瓷的居里温度随BLT掺杂量的增加向低温方向偏移,居里温度分别为:475℃,400℃,225℃,200℃,这是因为Ba2+和La3+进入钙钛矿A位,Ti4+进入钙钛矿B位,类似现象出现在KNN-xBT陶瓷中 [26] 。但BLT作为掺杂组分使KNN居里温度向低温移动的幅度比BT作为掺杂组分大;第三,室温到350℃范围内

Figure 1. Variation of density and sintering temperature for the KNN-xBLT ceramics

图1. 不同烧结温度下KNN-xBLT陶瓷的密度曲线图

Figure 2. SEM micrographs of KNN-xBLT ceramics: (a) x = 0.01, (b) x = 0.02, (c) x = 0.04, (d) x = 0.05

图2. KNN-xBLT陶瓷的SEM图:(a) x = 0.01,(b) x = 0.02,(c) x = 0.04,(d) x = 0.05

(a) (b)

(a) (b)

(c) (d)

(c) (d)

Figure 3. Temperature dependence of dielectric permittivity for KNN-xBLT ceramics

图3. KNN-xBLT陶瓷的介温图谱:(a) x = 0.01,(b) x = 0.02,(c) x = 0.04,(d) x = 0.05

KNN-xBLT陶瓷的介电常数随BLT掺杂量的增加而增大,与文献比较KNN-xBLT陶瓷室温到350℃范围内介电常数有很大的提高,KNN-xBLT陶瓷室温到350℃范围内最大介电常数达到4000;第四,x = 0.05时,KNN-xBLT陶瓷具有较宽的介电峰且随着测试频率的增大介电常数明显下降,说明0.95KNN-0.05BLT陶瓷具有弥散相变。

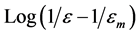

为进一步证明0.95KNN-0.05BLT陶瓷的弥散相变,图4显示了0.95KNN-0.05BLT陶瓷在10 kHz的 与

与 的变化关系。根据修正的居里-外斯定理,图中线的斜率决定g值,0.95KNN-0.05BLT陶瓷的弥散系数g经拟合为1.69,说明0.95KNN-0.05BLT陶瓷具有弥散相变。这可以有以下方面来理解:在(K0.5Na0.5)NbO3钙钛矿结构中的A位为Na+ (0.139 nm, CN = 12)和K+ (0.164 nm, CN = 12),B位为Nb5+ (0.064 nm, CN = 6)。根据离子半径匹配原则Ti4+ (0.074 nm, CN = 6)进入(K0.5Na0.5)NbO3钙钛矿结构的B位,取代Nb5+,而Ba2+和La3+的半径分别为0.135 nm和0.118 nm进入钙钛矿的A位取代(Na0.5K0.5)+。由于和原来的A位和B位离子带有不同的电荷,在A位和B位会形成局部的内电场;由于和原来的A位和B位离子具有不同的离子半径,在A位和B位会形成局部的弹力场。局部的内电场和弹力场组成了所谓的内场,这些内场的出现,阻碍了大量偶极子的耦合,只允许少量的偶极子耦合,形成了在尺度上从十几纳米到几十纳米的极性微区,由于内场的存在,这些极性微区不能继续耦合成尺度更大的铁电畴,而表现出弛豫铁电体的特征。

的变化关系。根据修正的居里-外斯定理,图中线的斜率决定g值,0.95KNN-0.05BLT陶瓷的弥散系数g经拟合为1.69,说明0.95KNN-0.05BLT陶瓷具有弥散相变。这可以有以下方面来理解:在(K0.5Na0.5)NbO3钙钛矿结构中的A位为Na+ (0.139 nm, CN = 12)和K+ (0.164 nm, CN = 12),B位为Nb5+ (0.064 nm, CN = 6)。根据离子半径匹配原则Ti4+ (0.074 nm, CN = 6)进入(K0.5Na0.5)NbO3钙钛矿结构的B位,取代Nb5+,而Ba2+和La3+的半径分别为0.135 nm和0.118 nm进入钙钛矿的A位取代(Na0.5K0.5)+。由于和原来的A位和B位离子带有不同的电荷,在A位和B位会形成局部的内电场;由于和原来的A位和B位离子具有不同的离子半径,在A位和B位会形成局部的弹力场。局部的内电场和弹力场组成了所谓的内场,这些内场的出现,阻碍了大量偶极子的耦合,只允许少量的偶极子耦合,形成了在尺度上从十几纳米到几十纳米的极性微区,由于内场的存在,这些极性微区不能继续耦合成尺度更大的铁电畴,而表现出弛豫铁电体的特征。

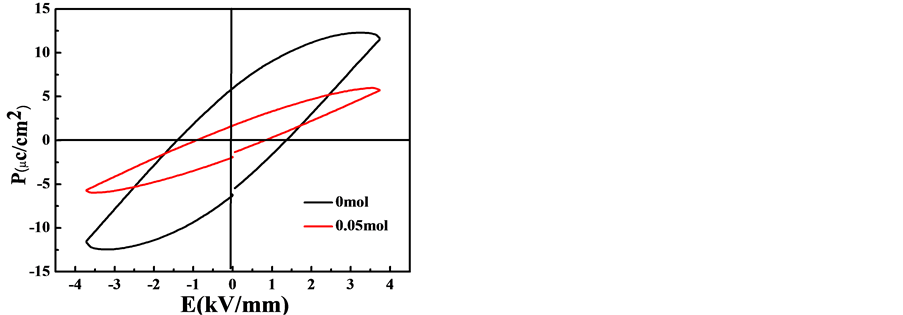

图5显示了0.95KNN-0.05BLT陶瓷在室温下的电滞回线图。由图可以看出,且0.95KNN-0.05BLT陶瓷的电滞回线比纯KNN陶瓷“瘦”。弛豫铁电陶瓷的另一个特征是具有“瘦”的电滞回线。根据钙钛矿正交相铁电体的自发极化方向在[110]方向,具有12个自发极化方向,四方相结构的铁电体具有6个自发极化方向。因此电滞回线与0.95KNN-0.05BLT陶瓷的XRD图相对应(见图7)。

图6是KNN-xBLT陶瓷在测试频率10 KHz下介电损耗随温度的变化曲线。由图可以看出测试温度从室温到350℃范围内,KNN-xBLT陶瓷的介电损耗随BLT掺杂量的增加而减小,这是与陶瓷的致密性增强,陶瓷晶粒尺寸减小变均匀有关。其中0.95KNN-0.05BLT陶瓷在室温到350℃范围内的介电损耗小于0.02。KNN-xBLT陶瓷的介电损耗在测试温度高于350℃时迅速增大主要是由于高温漏导损耗的影响。

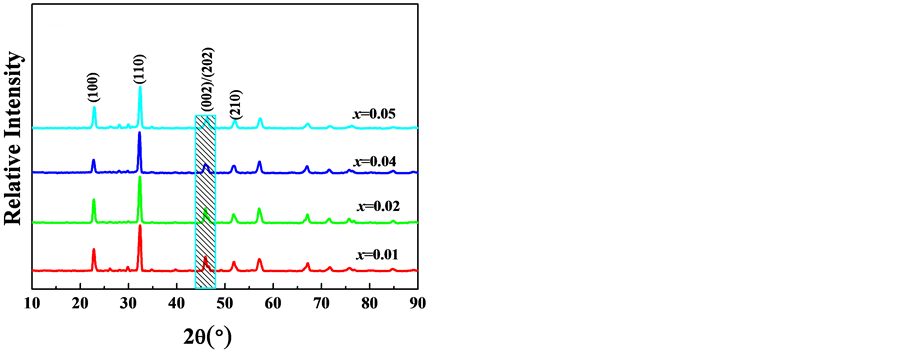

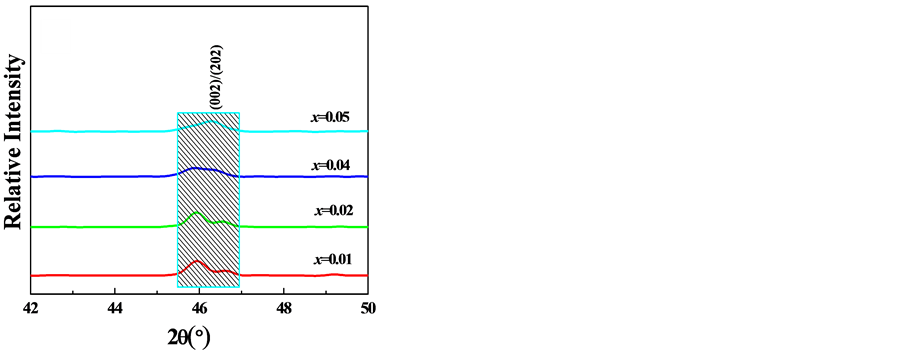

图7给出了KNN-xBLT陶瓷样品室温下的XRD图谱(27℃)。从图7(a)中可以看出,所研究的陶瓷样品均没有发现其他的杂相,为纯的钙钛矿结构。这个结果表明:BLT已经固溶于KNN中,形成单一钙钛矿结构的固溶体。研究表明:正交相的特征峰为45˚附近(202)和(020)双峰,四方相的特征峰为45˚附近(002)和(200)双峰 [28] 。根据这些特征峰和图7(b) KNN-xBLT陶瓷样品在40˚~50˚放大的XRD图谱,我们可以得出这样的结论:当x ≤ 0.02时,KNN-xBLT陶瓷为正交相钙钛矿结构,当x ≥ 0.05时,KNN-xBLT

Figure 4.  as a function of

as a function of  at 10 kHz for 0.95KNN-0.05BLT ceramics

at 10 kHz for 0.95KNN-0.05BLT ceramics

图4. 0.95KNN-0.05BLT陶瓷在10 kHz的 与

与 的变化关系图

的变化关系图

Figure 5. The room temperature polarization-electric field (P-E) hysteresis loops (at 1 Hz) for the KNN and 0.95KNN-0.05BLT ceramics sintered at the optimum sintering temperature

图5. KNN和0.95KNN-0.05BLT陶瓷在室温下的电滞回线图(测试频率:1 Hz)

Figure 6. Temperature dependence of dielectric loss for KNN-xBLT ceramics (at 10 KHz)

图6. KNN-xBLT陶瓷在测试频率10 KHz下的介电损耗图谱

(a)(b)

(a)(b)

Figure 7. XRD patterns of KNN-xBLT ceramics

图7. KNN-xBLT陶瓷样品的XRD图谱

陶瓷为四方相钙钛矿结构,当x = 0.04时,正交相和四方相特征峰都比较明显,KNN-xBLT陶瓷的相结构为正交相和四方相两相共存。这是因为根据晶体化学和离子半径匹配原则,Ti4+的半径为0.074 nm,接近Nb5+的离子半径(0.064 nm)进入钙钛矿结构六配位的B位。Ba2+和La3+的半径分别为0.135 nm和0.118 nm,所以进入钙钛矿的A位取代(Na0.5K0.5)+。因此,掺杂BLT使(K0.5Na0.5)NbO3的晶胞结构发生畸变并诱导了相结构变化。

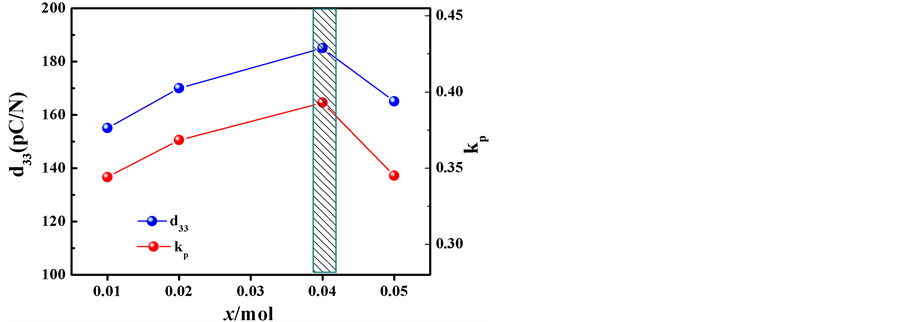

图8是KNN-xBLT陶瓷样品在室温下的压电性能。从图中可以清楚地看到,随着BLT含量的增加,样品的d33和kp均先增大后减小,当x = 0.04时,分别达到他们的最大值185 pC/N和0.39,这个结果明显的高于纯的KNN陶瓷的压电性能。另外,我们可以发现KNN-xBLT陶瓷的压电性能对组分特别敏感,当BLT的含量偏离0.04时,KNN-xBLT陶瓷的压电性能便会显著的降低,这种现象在KNN-BNT陶瓷中也有出现 [28] 。KNN-xBLT陶瓷在x = 0.04处表现出高压电性能的原因与其相结构有关。根据朗道-德尔希文理论和晶体学的结构对称性,KNN-xBLT (x = 0.04)陶瓷的相结构在室温下处于正交相和四方相共存的混合相时,自发极化方向有18个,电畴的稳定态方向也就有18个,电畴稳定态方向的增多导致极化时电畴被定向程度增加,会增加剩余极化强度Ps,同样剩余极化强度Ps的增加必然会导致压电性能的增加。第二,KNN-xBLT (x = 0.04)陶瓷的相结构在室温下是正交相和四方相共存,极化时非180畴更容易被定向,故,KNN-xBLT (x = 0.04)陶瓷表现出最高的压电性能。

4. 结论

本文采用固相烧结法制备KNN-xBLT (x = 0.01, 0.02, 0.04, 0.05)无铅陶瓷,对其相组成、微观形貌、电性能进行了分析。结果表明:

1) KNN-xBLT陶瓷的晶粒均为立方体。BLT的掺入抑制KNN-xBLT陶瓷晶粒的生长,随着BLT含量增加,陶瓷样品晶粒尺寸明显减小且更加均匀。

2) 在室温至350℃范围内,KNN-xBLT陶瓷的介电常数随着BLT掺杂量的增加而增加且居里温度向低温方向移动。0.95KNN-0.05BLT陶瓷是一种弛豫铁电体且在室温至350℃范围内最大介电常数4000,介电损耗小于0.02,暗示其在高温陶瓷电容器介质材料方面的应用潜力。

3) KNN-xBLT陶瓷的相结构随着BLT含量的增加由正交相向四方相转变。当x ≤ 0.02时,KNN-xBLT陶瓷为正交相,当x ≥ 0.05时,KNN-xBLT陶瓷为四方相。当x = 0.04时,KNN-xBLT陶瓷为正交相和四

Figure 8. Piezoelectric properties of KNN-xBLT ceramics at room temperature as a function of x

图8. KNN-xBLT陶瓷样品在室温下的压电性能

方相的混合相。0.96KNN-0.04BLT陶瓷因正交相和四方相共存压电性能有所提高(d33 = 185 pC/N, kp = 0.39),但距铅基压电陶瓷的性能还有差距。

基金项目

宝鸡文理学院重点项目(No. ZK15044),陕西省教育厅专项项目(No. 15JK1021),国家青年科学基金项目(No. 21501007)。

文章引用

程花蕾,肖 健,高 鹏,严云云,高拴平. (1-x)(K0.5Na0.5)NbO3-xBa0.985La0.01TiO3无铅陶瓷的微观结构及电性能研究

Microstructure and Electrical Properties of (1-x)(K0.5Na0.5)NbO3-xBa0.985La0.01TiO3 Lead-Free Ceramics[J]. 材料科学, 2017, 07(01): 39-47. http://dx.doi.org/10.12677/MS.2017.71006

参考文献 (References)

- 1. Suchanicz, J. (1995) Investigations of the Phase Transitions in Na0.5Bi0.5TiO3. Ferroelectrics, 172, 455-458. https://doi.org/10.1080/00150199508018512

- 2. Nagata, H. and Takenaka, T. (2001) Additive Effects on Electrical Properties of (Bi1/2Na1/2)TiO3 Ferroelectric Ceramics. Journal of the European Ceramic Society, 21, 1299-1302. https://doi.org/10.1016/S0955-2219(01)00005-X

- 3. Qu, Y.F., Shan, D., Song, J.J., et al. (2005) Effect of A-Site Substitution on Crystal Component and Dielectric Properties in Bi0.5Na0.5TiO3 Ceramics. Materials Science and Engi-neering: B, 121, 148-151. https://doi.org/10.1016/j.mseb.2005.03.023

- 4. Zhang, H.W., Deng, H., Chen, C., et al. (2014) Chemical Nature of Giant Strain in Mn-Doped 0.94(Na0.5Bi0.5) TiO3-0.06BaTiO3 Lead-Free Ferroelectric Single Crystals. Scripta Materialia, 75, 50-53. https://doi.org/10.1016/j.scriptamat.2013.11.017

- 5. Guo, Y.C., Fan, H.Q., Long, C.B., et al. (2014) Electromechanical and Electrical Properties of Bi0.5Na0.5Ti1-xMnxO3-δ Ceramics with High Remnant Polarization. Journal of Alloys and Compounds, 610, 189-195. https://doi.org/10.1016/j.jallcom.2014.04.038

- 6. Lee, Y.C., Lee, T.K., Jan, J.H., et al. (2011) Piezoelectric Properties and Microstructures of ZnO-Doped Bi0.5Na0.5TiO3 Ceramics. Journal of the European Ceramic Society, 31, 3145-3152. https://doi.org/10.1016/j.jeurceramsoc.2011.05.010

- 7. Liu, X.M., Guo, H.Z., Tan, X.L., et al. (2014) Evolution of Structure and Electrical Properties with Lanthanum Content in[(Bi1/2Na1/2)0.95Ba0.05]1−xLaxTiO3 Ceramics. Journal of the European Ceramic Society, 34, 2997-3006. https://doi.org/10.1016/j.jeurceramsoc.2014.03.017

- 8. Lu, W.Z., Wang, Y., Fan, G.F., et al. (2011) The Structural and Electric Properties of Li- and K-Substituted Bi0.5Na0.5TiO3 Ferroelectric Ceramics. Journal of Alloys and Compounds, 509, 2738-2744. https://doi.org/10.1016/j.jallcom.2010.10.041

- 9. Wu, J.G., Xiao, D.Q. and Zhu, J.G. (2015) Potassium-Sodium Ni-obate Lead-Free Piezoelectric Materials: Past, Present, and Future of Phase Boundaries. Chemical Reviews, 115, 2559-2595. https://doi.org/10.1021/cr5006809

- 10. Zhang, B.Y., Wu, J.G., Cheng, X.J., et al. (2013) Lead-Free Pie-zoelectrics Based on Potassium-Sodium Niobate with Giant d33. ACS Applied Materials & Interfaces, 5, 7718-7725. https://doi.org/10.1021/am402548x

- 11. Wang, X.P., Wu, J.G., Xiao, D.Q., et al. (2014) Giant Piezoelectricity in Po-tassium-Sodium Niobate Lead-Free Ceramics. Journal of the American Chemical Society, 136, 2905-2910. https://doi.org/10.1021/ja500076h

- 12. Wu, J.G. and Wang, Y.M. (2014) Two-Step Sintering of New Potassium So-dium Niobate Ceramics: A High D33 and Wide Sintering Temperature Range. Dalton Transactions, 43, 12836-12841. https://doi.org/10.1039/C4DT01712A

- 13. Zheng, T., Wu, J.G., Cheng, X.J., et al. (2014) New Potassium-Sodium Niobate Material System: A Giant-D33 and High-TC Lead-Free Piezoelectric. Dalton Transactions, 43, 11759-11766. https://doi.org/10.1039/C4DT01293C

- 14. Cha, M.S., Koh, J.H. and Lee, S.K. (2014) Influence of the Sintering Temperature and Ag2O Dopants on Microstructure and Piezoelectric Properties of 0.94(Na0.5K0.5)NbO3−0.06LiNbO3 Lead-Free Ceramics. Journal of Alloys and Compounds, 587, 729-732. https://doi.org/10.1016/j.jallcom.2013.11.021

- 15. Li, F.X, Xiao, D.Q., Wu, J.G., Wang, Z., Liu, C. and Zhu, J. (2014) Phase Structure and Electrical Properties of (Na0.5K0.5)NbO3−(Bi0.5Na0.5)ZrO3 Lead-Free Ceramics with a Sintering aid of ZnO. Ceramics International, 40, 14601- 14605. https://doi.org/10.1016/j.ceramint.2014.06.045

- 16. Wang, H., Zhai, X., Xu, J.W., Yuan, C. and Zhou, C. (2013) Effects of CuO Doping on the Structure and Properties Lead-Free KNN-LS Piezoelectric Ceramics. Journal of Materials Science: Materials in Electronics, 24, 2469-2472. https://doi.org/10.1007/s10854-013-1119-0

- 17. Kanga, I.Y., Seoa, I.T., Cha, Y.J., et al. (2012) Low Temperature Sintering of ZnO and MnO2-Added (Na0.5K0.5)NbO3 Ceramics. Journal of the European Ceramic Society, 32, 2381-2387. https://doi.org/10.1016/j.jeurceramsoc.2012.01.030

- 18. Azough, F., Wegrzyn, M., Freer, R., Sharma, S. and Hall, D. (2011) Microstructure and Piezoelectric Properties of CuO Added (K, Na, Li)NbO3 Lead-Free Piezoelectric Ceramics. Journal of the European Ceramic Society, 31, 569- 576. https://doi.org/10.1016/j.jeurceramsoc.2010.10.033

- 19. Jaeger, R.E. and Egerton, L. (1962) Hot Pressing of Potassium Sodium Niobates. Journal of the American Ceramic Society, 45, 209-213. https://doi.org/10.1111/j.1151-2916.1962.tb11127.x

- 20. Zhang, B.P., Zhang, L.M., Li, J.F., Zhang, H.L. and Jin, S.Z. (2005) SPS Sintering of NaNbO3-KNbO3 Piezoelectric Ceramics. Material Science Forum, 475-479, 1165-1168. https://doi.org/10.4028/www.scientific.net/MSF.475-479.1165

- 21. Lopez, R., Gonzalez, F., Cruz, M.P. and Villa-fuerte-Castrejon, M.E. (2011) Piezoelectric and Ferroelectric Properties of K0.5Na0.5NbO3 Ceramics Synthesized by Spray Drying Method. Materials Research Bulletin, 46, 70-74. https://doi.org/10.1016/j.materresbull.2010.09.034

- 22. Ha, J.Y. and Choi, J.W. (2014) Improved Piezoelectric Prop-erties of Lead-Free (1−x)(Na0.5K0.5)NbO3-x(Ba0.95 Sr0.05)TiO3 Ceramics by Particle Size Control. Ceramics International, 40, 12023-12028. https://doi.org/10.1016/j.ceramint.2014.04.041

- 23. Zheng, T., Wu, J.G., Xiao, D.Q. and Zhu, J. (2015) Giant D33 in Nonstoichiometric (K,Na)NbO3-Based Lead-Free Ceramics. Scripta Materialia, 94, 25-27. https://doi.org/10.1016/j.scriptamat.2014.09.008

- 24. Cheng, H.L., Du, H.L. and Zhou, W.C. (2013) Bi(Zn2/3Nb1/3)O3-(K0.5Na0.5)NbO3 High-Temperature Lead-Free Ferroelectric Ceramics with Low Capacitance Variation in a Broad Temperature Usage Range. Journal of the American Ceramic Society, 96, 833-837. https://doi.org/10.1111/jace.12118

- 25. Jiang, L.M., Xing, J., Tan, Z., et al. (2016) High Piezoelectricity in (K,Na)(Nb,Sb)O3-(Bi,La,Na,Li)ZrO3 Lead-Free Ceramics. Journal of Materials Science, 51, 4963-4972. https://doi.org/10.1007/s10853-016-9801-2

- 26. Lu, Y.T., Chen, X.M., Jin, D.Z. and Hu, X. (2005) Dielectric and Ferroelectric Properties of (1−x)(Na0.5K0.5)NbO3− xBaTiO3 Ceramics. Materials Research Bulletin, 40, 1847-1855. https://doi.org/10.1016/j.materresbull.2005.04.044

- 27. Lu, D.Y., Yue, Y. and Sun, X.Y., (2014) Novel X7R BaTiO3 Ceramics Co-Doped with La3+ and Ca2+ Ions. Journal of Alloys and Compounds, 586, 136-141. https://doi.org/10.1016/j.jallcom.2013.10.055

- 28. Du, H.L., Zhou, W.C., Luo, F., et al. (2008) Sintering Characteristic, Microstructure, and Dielectric Relaxor Behavior of (K0.5Na0.5)NbO3-(Bi0.5Na0.5)TiO3 Lead-Free Ceramics. Journal of the American Ceramic Society, 91, 2903-2909. https://doi.org/10.1111/j.1551-2916.2008.02528.x

*通讯作者。